Specialty trim repair requires seamless integration with vehicle surfaces, flawless paint application, and high-quality materials, tools for lasting durability. Cheaper alternatives risk subpar outcomes compromising aesthetics. Regular inspection is crucial to avoid frequent touch-ups after shoddy repairs.

In the realm of home improvement, specialty trim repair projects demand meticulous craftsmanship. However, signs of poor workmanship can mar the final result, leading to unsightly defects and reduced longevity. This article guides you through identifying visible issues, from uneven surfaces to low-quality materials and tools. Learn to recognize red flags that indicate a job poorly done, ensuring your investment in specialty trim repair yields a durable, aesthetically pleasing outcome.

- Identifying Visible Defects and Unevenness

- Materials and Tools: A Sign of Quality or Compromise?

- Longevity and Durability: Red Flags to Watch Out For

Identifying Visible Defects and Unevenness

When it comes to specialty trim repair, visible defects and unevenness are clear indicators of poor workmanship. Upon close inspection, a professionally executed repair should exhibit seamless integration with the surrounding vehicle surfaces. Any visible gaps, misalignments, or uneven finishes suggest that the job was not done meticulously. For instance, if the repaired area appears lower or higher than adjacent panels, it points to subpar frame straightening techniques during the process.

Additionally, car paint services that are part of a specialty trim repair project should be free from blemishes and imperfections. Uneven paint application, noticeable touch-ups, or distinct color variations can all signal that the automotive body work was not carried out by skilled professionals. These defects not only compromise the aesthetic appeal but also affect the long-term durability of the vehicle’s exterior.

Materials and Tools: A Sign of Quality or Compromise?

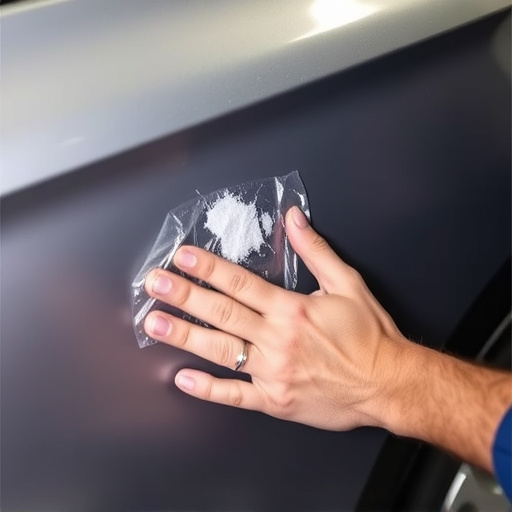

The choice of materials and tools is a critical indicator of workmanship in any specialty trim repair project. High-quality products are essential for ensuring durability and longevity of the repair. Professional technicians invest in top-tier materials, from fine finishes to specialized adhesives, as these directly impact the final result. Cheaper alternatives may seem appealing, but they often lead to subpar outcomes, with repairs that lack finesse and fail to blend seamlessly with the existing trim.

Furthermore, the tools employed can expose the level of expertise and commitment to quality. Outdated or poorly maintained tools can leave marks, scratches, or inconsistent finishes, indicating a compromise in workmanship. Conversely, modern, well-maintained toolsets demonstrate an investment in precision and attention to detail, ensuring that every aspect of the repair is executed with care, resulting in a professional and flawless finish, much like those seen in top-tier car restoration and tire services for minor scuffs and car scratch repairs.

Longevity and Durability: Red Flags to Watch Out For

When it comes to specialty trim repair, longevity and durability should be a top priority. Red flags that indicate poor workmanship often manifest in the form of short-lived repairs. If you notice that freshly repaired areas start showing signs of damage or deterioration within a short period, it’s a clear indication of subpar work. For instance, flaking or peeling paint, visible gaps or misalignments, and weak adhesion between the repair and the original trim are all red flags. These issues not only compromise the aesthetic appeal but also suggest that the underlying structure is not as robust as it should be.

In the realm of auto maintenance, including fender repair and car bodywork services, craftsmanship is paramount. Skilled technicians understand the importance of using high-quality materials and applying proper techniques to ensure repairs stand the test of time. In contrast, shoddy workmanship can lead to ongoing issues, requiring frequent touch-ups or complete redo jobs. Therefore, when investing in specialty trim repair, it’s crucial to scrutinize the work for any signs of haste or carelessness, ensuring that your vehicle retains its beauty and value over the long term.

In assessing the quality of specialty trim repair projects, paying close attention to visible defects, material choices, and long-term durability is paramount. By identifying uneven surfaces, subpar tools and materials, and signs of wear or damage early on, homeowners and professionals alike can avoid costly repairs down the line. Choosing high-quality components and employing skilled craftsmanship ensures these intricate details not only look excellent but also withstand the test of time, preserving the beauty and value of any property.