Tri-coat paint repair involves a meticulous process: damage assessment, frame straightening, preparation (cleaning, sanding, priming), base coat application for color and protection, followed by a clear top coat for durability and gloss. Realistic timeline planning considers complex repairs and environmental factors. Auto body shops achieve exceptional results through streamlined processes, advanced techniques, structured quality control, and technological advancements in color matching, enhancing customer satisfaction.

“In the realm of automotive restoration, tri-coat paint repair stands out as a meticulous process demanding precision and time. This article navigates the intricate timeline expectations of tri-coat paint repair projects. From understanding the fundamental steps to setting realistic stages and optimizing efficiency, we delve into ensuring quality control. By exploring these aspects, folks can anticipate smoother, more effective outcomes in their restoration endeavors.”

- Understanding Tri-Coat Paint Repair Process

- Setting Realistic Timelines for Each Stage

- Optimizing Efficiency and Quality Control

Understanding Tri-Coat Paint Repair Process

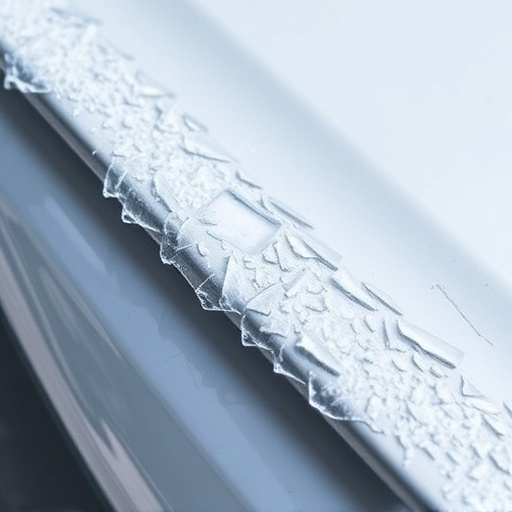

The tri-coat paint repair process involves a meticulous approach to restoring the exterior of a vehicle to its original condition. It begins with an extensive assessment to identify damage, including dents, scratches, and rust spots. This initial step is crucial as it determines the extent of the work required. Once the damage is accurately assessed, the frame straightening process can commence. This involves realigning any distorted metal panels to ensure a smooth, even surface for painting.

After frame straightening, the vehicle undergoes a meticulous preparation stage. This includes surface cleaning, sanding, and priming to create a clean canvas for the tri-coat paint job. The first coat of paint, known as the base coat, is carefully applied, often in a specialized auto repair shop, to provide color and protection. Subsequently, a clear top coat is added to seal and protect the base, creating a durable, glossy finish. This multi-step process ensures not just an aesthetically pleasing vehicle restoration but also long-lasting protection for the paintwork.

Setting Realistic Timelines for Each Stage

Setting realistic timelines is key to managing expectations for any tri-coat paint repair project. Each stage of the process, from initial assessment and surface preparation to priming and final coating, has its own unique requirements and potential delays. For instance, allowing sufficient time for complex surface repairs, such as filling and sanding, is crucial to ensuring a smooth base for subsequent coats. Similarly, environmental factors like temperature and humidity can impact drying times, requiring adjustments in the schedule.

Understanding these variables empowers both professionals and clients. Clients should be informed about potential timelines for each stage, enabling them to plan their schedules accordingly. For vehicle repair services focusing on car body restoration, setting clear expectations from the outset fosters trust and ensures everyone involved is on the same page. Remember that while aiming for efficiency, flexibility is essential to accommodate unexpected challenges, ensuring a high-quality outcome in every car body repair task.

Optimizing Efficiency and Quality Control

In the realm of tri-coat paint repair, optimizing efficiency and quality control are paramount to delivering exceptional results. By implementing structured processes and utilizing advanced techniques, auto body repair shops can streamline their work, ensuring each step aligns seamlessly with the next. This approach not only reduces turnaround time but also minimizes the likelihood of errors, leading to higher customer satisfaction.

Quality control measures, such as regular inspections and meticulous attention to detail, play a crucial role in maintaining consistency across all auto body repairs, including scratch repair and vehicle paint repair services. Additionally, leveraging technology for color matching and application can significantly enhance accuracy, making every repair job a testament to precision craftsmanship.

In conclusion, successfully managing a tri-coat paint repair project requires a deep understanding of the process, realistic timeline expectations, and efficient quality control. By setting clear goals for each stage—from preparation to final inspection—professionals can ensure top-notch results while meeting client expectations. Optimizing these aspects is key to delivering high-quality, long-lasting tri-coat paint repairs.