Tesla aluminum welding certification ensures safe, high-quality repairs for modern and classic vehicles using lightweight aluminum components. The rigorous process includes strict guidelines, proficiency in Tesla-specific parts, and adherence to safety protocols, maintaining structural integrity, aesthetics, and long-term performance, aligning with Tesla's innovation and quality standards.

Tesla’s commitment to innovation extends to its aluminum welding processes, with a recently introduced certification program setting new standards in safety and quality. This comprehensive guide delves into the stringent guidelines that welders must adhere to, ensuring every joint is not just structurally sound but also safe for both workers and the environment. Through rigorous testing and training, Tesla certifies welders, guaranteeing superior craftsmanship across its global operations.

- Tesla Aluminum Welding Certification: Safety First

- Strict Guidelines for Certified Welders

- Ensuring Quality through Rigorous Standards

Tesla Aluminum Welding Certification: Safety First

Tesla aluminum welding certification is a critical aspect of ensuring safety and quality in both modern and classic vehicle repair services. With aluminum becoming increasingly prevalent in automotive manufacturing, especially in models designed for sustainability, proper welding techniques are essential to prevent structural weaknesses or failures. The certification process sets strict guidelines to educate and equip technicians with the knowledge to handle these delicate processes safely.

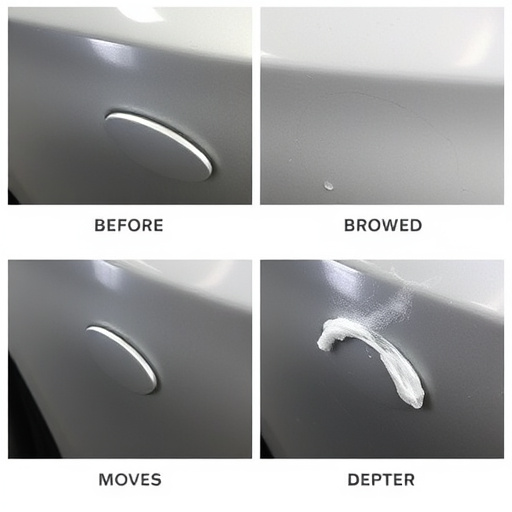

This certification prioritizes not just the integrity of new vehicles but also classic car restoration projects. By adhering to stringent safety protocols, welders can effectively mitigate risks associated with hail damage repair, ensuring that every joint is as strong as the day it was factory-built. This commitment to excellence not only guarantees the structural soundness of repaired or restored vehicles but also reinforces Tesla’s reputation for cutting-edge technology and rigorous quality control in vehicle manufacturing.

Strict Guidelines for Certified Welders

The Tesla aluminum welding certification process is governed by stringent safety guidelines designed to ensure the highest quality and reliability in all welds. These guidelines cover everything from the types of equipment allowed to the specific techniques employed, with a particular focus on minimizing hazards associated with high-temperature metalwork. For instance, certified welders must use approved welding procedures and materials that meet Tesla’s exacting standards, while adhering to strict personal protective equipment (PPE) protocols to safeguard against burns, arcs, sparks, and other potential dangers.

Furthermore, the certification requires welders to demonstrate proficiency in handling and manipulating aluminum sheets and components specific to Tesla vehicles, including vehicle bodywork, fender benders, and other intricate parts. This involves mastering techniques to ensure structural integrity, aesthetics, and long-term performance of the welded sections, reflecting Tesla’s commitment to both innovation and safety in their electric vehicles.

Ensuring Quality through Rigorous Standards

Achieving a Tesla aluminum welding certification is not merely about mastering the technique; it’s a commitment to upholding uncompromising quality standards. The process is meticulously designed to ensure every weld meets or exceeds the rigorous criteria set forth by Tesla for their high-quality, lightweight aluminum construction. This involves not just technical proficiency but also adherence to strict safety guidelines, as missteps in this intricate process could compromise structural integrity and vehicle performance.

The certification program encompasses comprehensive training on best practices specific to Tesla vehicles, focusing on both efficiency and precision. Welders undergo rigorous testing to demonstrate their ability to create robust bonds while maintaining the aesthetic integrity of the vehicle body—a critical factor for luxury vehicle repair, given the meticulous craftsmanship expected in the Tesla brand. This emphasis on quality ensures that any repairs or modifications involving Tesla aluminum welding adhere to the same stringent standards that have made Tesla vehicles renowned for their advanced engineering and sleek design.

The Tesla Aluminum Welding Certification sets a new standard in the industry, ensuring that all welders adhere to strict safety guidelines. By implementing these rigorous protocols, Tesla promotes not only superior quality but also fosters a culture of safety within its manufacturing processes. This commitment to excellence is what makes the Tesla aluminum welding certification a game-changer in the automotive sector.