Mercedes gap measurement standards are crucial for ensuring precision and quality in automotive body shop repairs and auto painting. Accurate measurements guarantee perfect alignment, aesthetics, and structural integrity, with final delivery inspections checking paint finish, panel gaps, and body condition. Meticulous checks, including precise Mercedes gap measurements, are vital for flawless vehicle handovers in the luxury automotive sector, preserving original design and safety features through skilled technician use of specialized tools.

Ensure a seamless transition with accurate Mercedes gap measurement during final delivery checks. This critical process guarantees that Mercedes-Benz vehicles meet stringent quality standards before reaching buyers. Understanding the Mercedes gap measurement requirements is essential for dealership success and customer satisfaction. From suspension alignment to wheel spacing, this article explores key components, precision techniques, and best practices to streamline your final delivery inspection procedures.

- Understanding Mercedes Gap Measurement Standards

- Key Components in Final Delivery Inspection

- Ensuring Precision for Seamless Vehicle Turnover

Understanding Mercedes Gap Measurement Standards

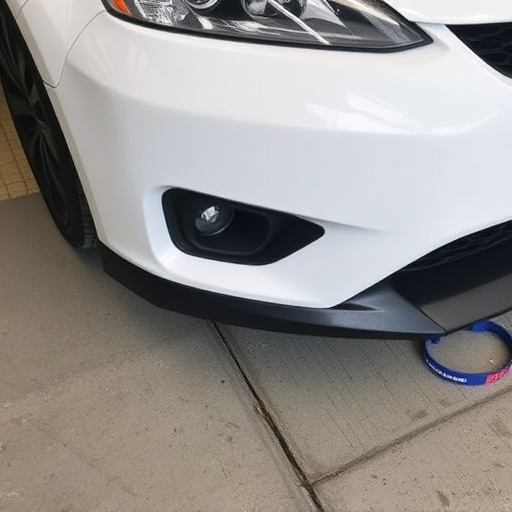

Mercedes gap measurement standards are crucial for maintaining the precision and quality that Mercedes-Benz is renowned for. In the world of automotive body shop repairs and auto painting, achieving accurate measurements is vital to ensure a seamless fit during final delivery checks. This meticulous process involves assessing various aspects of the vehicle’s body, including panel gaps, which determine the overall alignment and aesthetics of the finished product.

For an automotive restoration project, understanding these standards is essential. Proper gap measurement ensures that every curve, contour, and edge of the vehicle’s exterior aligns perfectly, creating a stunning finish that reflects the brand’s commitment to excellence. It’s worth noting that in contrast to a simple visual inspection, Mercedes gap measurement involves precise tools and techniques, ensuring that even the most subtle details are considered, making it a game-changer for professionals in the auto painting and automotive restoration fields.

Key Components in Final Delivery Inspection

The final delivery inspection of a Mercedes-Benz is a meticulous process designed to ensure every detail meets the brand’s exceptional standards. Key components in this rigorous checklist include a comprehensive Mercedes gap measurement, examining the car’s alignment and spacing between various parts. This step is vital for maintaining the vehicle’s aesthetic appeal and structural integrity, which are hallmarks of a premium automotive repair experience.

Additionally, the inspection delves into other critical areas such as paint finish, panel gaps, and overall body condition, especially when dealing with a car body shop specializing in Mercedes-Benz models. These meticulous checks are crucial to guarantee that any repairs or restoration work conducted at an automotive repair facility has been executed flawlessly, reflecting the brand’s renowned craftsmanship and precision, whether it’s for routine maintenance or extensive car body restoration.

Ensuring Precision for Seamless Vehicle Turnover

In the automotive industry, especially when dealing with luxury brands like Mercedes-Benz, precision is paramount during final delivery checks. Ensuring that every detail is up to standard sets the stage for a seamless vehicle turnover experience. One critical aspect often overlooked but crucial for maintaining quality is the accurate measurement of gaps between various components of the car body. Known as Mercedes gap measurement, this process plays a significant role in collision repair and autobody repairs, guaranteeing that all parts fit perfectly together, resulting in an aesthetically pleasing and structurally sound vehicle.

Accurate measurements ensure that any adjustments made during the repair process align with the manufacturer’s specifications. This level of detail is essential for maintaining the vehicle’s original design integrity, particularly in areas visible to the naked eye or integral to safety features. Skilled technicians utilize specialized tools to gauge these gaps, ensuring every Mercedes-Benz delivered meets the highest standards, both internally and externally, across all autobody repairs performed.

Mercedes gap measurement plays a crucial role in ensuring seamless vehicle turnover and customer satisfaction during final delivery checks. By understanding and adhering to established standards, as well as precisely measuring key components, Mercedes-Benz dealers can guarantee that each vehicle meets the highest quality criteria. This meticulous approach fosters trust among clients and solidifies Mercedes’ reputation for excellence.