TIG welding auto body is a revolutionary technique in vehicle repair and restoration, offering precise, strong metal fusion with minimal heat input. Its benefits include superior strength, durability, and precision reproduction of original designs, making it ideal for structural repairs and aesthetic enhancements. TIG welding minimizes damage to surrounding materials, especially in delicate restoration work, ensuring damaged auto bodies are restored seamlessly to their original condition, ready for subsequent painting processes.

TIG welding auto body has emerged as a game-changer in vehicle repair, offering precise and durable solutions. This article delves into the intricate world of TIG welding, exploring its techniques and benefits specifically tailored for auto body work. We’ll guide you through the meticulous process, highlighting its advantages and challenges. Discover why this method is the preferred choice for repairing and restoring vehicles, ensuring long-lasting strength and aesthetics.

- Understanding TIG Welding Auto Body: Techniques and Benefits

- The Process of TIG Welding in Vehicle Repair

- Advantages and Challenges: Why It's a Preferred Choice for Auto Body Work

Understanding TIG Welding Auto Body: Techniques and Benefits

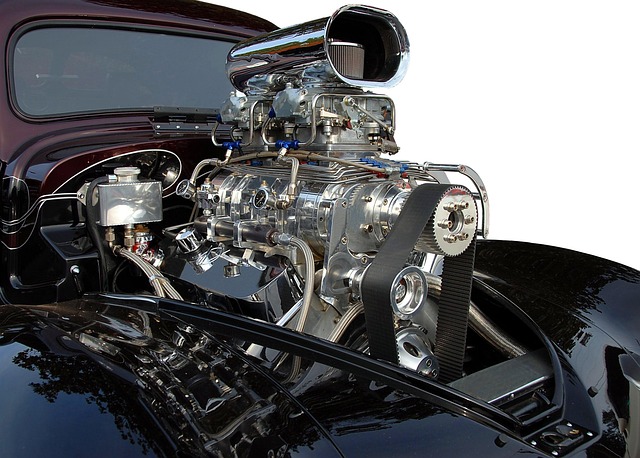

TIG welding auto body is a specialized technique that has transformed the landscape of vehicle repair and restoration. This advanced process involves using a tungsten inert gas torch to fuse metal components together, creating strong and precise bonds. By focusing on precision and control, TIG welding allows for intricate designs and complex shapes, making it ideal for both structural repairs and aesthetic enhancements in auto body services.

The benefits of TIG welding auto body are numerous. It offers superior strength and durability compared to traditional welding methods, ensuring the longevity of vehicle structures. This technique is particularly advantageous in auto body repair and restoration projects, as it enables precise reproduction of original designs and intricate details. Moreover, TIG welding generates minimal heat input, reducing the risk of metal distortion or damage to surrounding materials, making it a preferred method for delicate auto body restoration work.

The Process of TIG Welding in Vehicle Repair

TIG welding auto body is a specialized technique that has revolutionized vehicle repair and restoration. This process involves using a non-consumptive welding method where a small, concentrated heat source is employed to melt and join metal. A protective gas environment is maintained during the weld, ensuring minimal contamination from oxygen, which can cause porosity in the final joint. The result is a strong, precise, and clean connection between the auto body parts.

In a collision center or car restoration setting, TIG welding offers unparalleled precision. It allows for intricate and complex welds on delicate components, such as panels, frames, and fenders, without damaging surrounding materials or affecting the overall aesthetic of the vehicle. This meticulous approach is particularly beneficial in fine-tuning damaged auto bodies, ensuring they return to their original condition after repairs, including auto painting processes.

Advantages and Challenges: Why It's a Preferred Choice for Auto Body Work

TIG welding auto body has emerged as a preferred choice for vehicle repair and restoration due to its unique advantages. This highly precise method allows for detailed and intricate work, ensuring structural integrity and superior quality finishes in car bodywork services. The use of a non-consumable electrode and controlled heat input enables TIG welders to produce strong, clean, and aesthetically pleasing joints, rivaling the original craftsmanship of auto body restoration.

Despite its benefits, TIG welding auto body also presents certain challenges. The process requires skilled labor and specialized equipment, making it potentially costlier than some other welding methods. Additionally, the need for a protective atmosphere around the weld pool can lead to longer completion times. However, these challenges are often outweighed by the superior strength and durability of TIG-welded components, ensuring vehicles not only look like new but also maintain enhanced structural integrity over time, enhancing safety and performance.

TIG welding auto body has emerged as a preferred choice in vehicle repair due to its precision, strength, and versatility. This article has explored the techniques and benefits of TIG welding, detailed the process involved, and highlighted the advantages and challenges it presents compared to other methods. By understanding these aspects, it’s clear that TIG welding offers superior results, ensuring vehicles not only look good but also maintain structural integrity. As a result, it remains a go-to solution for professional auto body work.