The Mercedes diagnostic system, powered by Advanced Driver Assistance Systems (ADAS), relies on sensors like cameras, radar, lidar, and ultrasonic transducers for safety features. Regular checks and maintenance are crucial to ensure proper sensor calibration, prevent errors, and maintain optimal performance of ADAS and active safety systems, enhancing driving experience and vehicle value.

“Uncover the intricacies of the Mercedes diagnostic system, a sophisticated network that enhances both vehicle performance and safety. This article guides you through the core components, starting with an overview of the architecture and its advanced driver assistance systems (ADAS). We then delve into practical check procedures for ADAS, followed by essential tips for calibrating and troubleshooting safety sensors. Discover how regular maintenance of these systems ensures optimal Mercedes performance and passenger protection.”

- Understanding Mercedes Diagnostic System Architecture

- ADAS (Advanced Driver Assistance Systems) Check Procedures

- Safety Sensor Calibration and Troubleshooting Tips

Understanding Mercedes Diagnostic System Architecture

The Mercedes diagnostic system is a complex network designed to monitor and optimize vehicle performance and safety. At its core, it incorporates Advanced Driver Assistance Systems (ADAS) that utilize a myriad of sensors to detect and predict potential hazards on the road. These sensors include cameras, radar, lidar, and ultrasonic transducers strategically placed throughout the vehicle. Each sensor captures critical data about the car’s surroundings, which is then processed by powerful onboard computers. This architecture allows for real-time analysis, enabling the system to make split-second decisions to enhance safety features like adaptive cruise control, lane keeping assist, and collision avoidance systems.

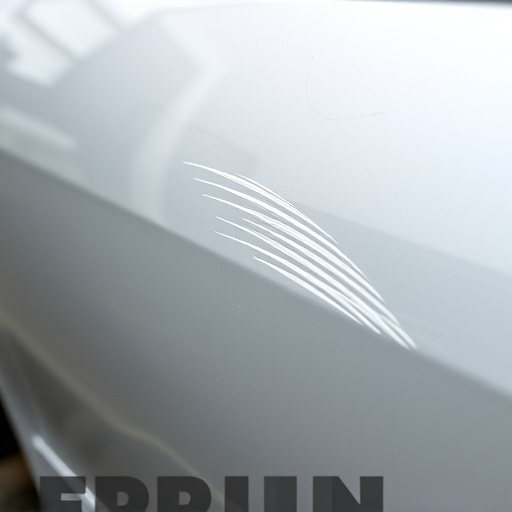

Understanding this diagnostic system architecture is crucial for vehicle restoration and repair professionals. When a car undergoes paintless dent repair or more extensive body work, ensuring that these sensors are properly calibrated and functioning is essential. Skilled technicians recognize the importance of checking ADAS components as part of comprehensive car body repair services, guaranteeing not just aesthetic restoration but also safety systems that operate flawlessly.

ADAS (Advanced Driver Assistance Systems) Check Procedures

The Mercedes diagnostic system incorporates Advanced Driver Assistance Systems (ADAS) that require regular checks to ensure optimal performance and safety. These checks are designed to monitor various sensors and components critical for ADAS functionality, such as cameras, lidars, radars, and ultrasonic sensors. Automotive repair services specialists use advanced tools to perform comprehensive scans, identifying any malfunctions or anomalies in the system.

During an ADAS check, a vehicle body shop technician will first connect a diagnostic scanner to the Mercedes’ onboard computer. This enables them to retrieve error codes and data from the ADAS modules, which can then be analyzed to pinpoint issues. Common problems may include sensor calibration errors, faulty wiring, or damaged components. Proper maintenance and timely repairs are crucial to ensure the continued effectiveness of these safety features, enhancing overall driving experience and vehicle value.

Safety Sensor Calibration and Troubleshooting Tips

Maintaining accurate calibration of safety sensors is paramount for a Mercedes diagnostic system to function at its optimal level. These sensors play a crucial role in Advanced Driver Assistance Systems (ADAS) and active safety features, ensuring the vehicle can accurately detect and react to its surroundings. Over time, sensor drift or damage can occur, leading to potential safety risks. Therefore, regular calibration checks are essential.

When troubleshooting sensor issues, automotive repair specialists should follow a systematic approach. Begin by verifying that sensors are clean and free from debris. Next, check for any loose connections, as even a minor tremor could disrupt the signal. For more complex problems, using specialized diagnostic tools can help identify faulty sensors or wiring issues. Interestingly, even services like car dent removal near these sensors can inadvertently cause disruptions if not performed correctly, underlining the need for precise maintenance and repair techniques to keep Mercedes’ advanced systems running smoothly.

Mercedes’ diagnostic system, encompassing Advanced Driver Assistance Systems (ADAS) and safety sensor checks, is a game-changer in vehicle technology. By understanding its architecture and implementing regular checks, owners can ensure optimal performance and enhanced safety features. This system’s capability to monitor and calibrate various sensors enables drivers to navigate the road with confidence, making it a cornerstone of modern automotive engineering.