Plasma cutting collision repair revolutionizes automotive services with precise, clean cuts on various materials, minimizing heat impact and waste. This advanced technique, requiring strict best practices and safety gear, offers complex shapes, tight tolerances, and high-quality finishes while prioritizing employee well-being and environmental safety. Embracing plasma cutting is crucial for modern auto repair's competitiveness and efficiency, delivering superior bodywork results.

In the realm of automotive collision repair, adopting advanced technologies is crucial for shops to stay competitive. Plasma cutting collision repair stands out as a game-changer, offering precision and efficiency unmatched by traditional methods. This article delves into the heart of plasma cutting technology, exploring its advantages in shop environments, and providing best practices for safe and effective implementation. Discover why this innovative approach is revolutionizing the industry for good.

- Understanding Plasma Cutting Technology for Collision Repair

- Advantages of Using Plasma Cutting in Shops

- Best Practices and Safety Measures for Plasma Cutting Collision Repair

Understanding Plasma Cutting Technology for Collision Repair

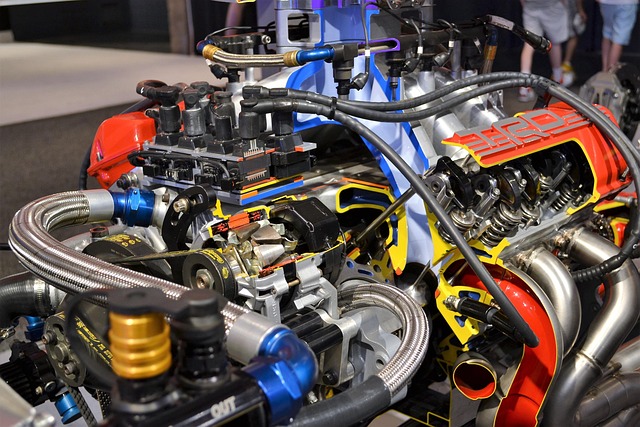

Plasma cutting technology has revolutionized collision repair in shops, offering a highly precise and efficient method for metal fabrication. This advanced technique involves using a plasma arc to cut through various materials, including damaged vehicle bodies, with exceptional accuracy. By ionizing gas into a high-energy plasma stream, the process allows for clean, fast, and precise cuts, ensuring minimal heat input and reduced material distortion.

In the context of car bodywork services and vehicle body repair, plasma cutting collision repair provides numerous benefits. It enables technicians to create complex shapes, make intricate cuts, and achieve tight tolerances, all while minimizing the risk of damage to surrounding areas. This level of precision is critical for restoring vehicles to their original specifications, ensuring a high-quality finish that meets industry standards.

Advantages of Using Plasma Cutting in Shops

In modern auto repair shops, embracing advanced technologies is key to staying competitive and delivering top-notch service. Plasma cutting collision repair stands out as a game-changer in this regard. This innovative technique offers numerous advantages over traditional cutting methods, making it a favorite among body shop services professionals. Not only does plasma cutting provide precise and clean cuts on various materials, including metal and plastic, but it also ensures minimal heat impact, preserving the integrity of the surrounding components.

By utilizing plasma cutting, auto repair shops can significantly streamline their bodywork services. It enhances efficiency by reducing preparation time and minimizing post-cutting treatments. Moreover, plasma cutting collision repair is an eco-friendly option, as it generates minimal waste compared to other methods, contributing to a more sustainable environment within the shop’s operations. These benefits collectively contribute to why many are turning to this technology for superior results in car bodywork services.

Best Practices and Safety Measures for Plasma Cutting Collision Repair

When engaging in plasma cutting collision repair, adhering to best practices and safety measures is paramount. This advanced technique, involving focused ion beams to cut or etch materials with precision, requires strict adherence to guidelines to ensure efficiency and prevent accidents. Safety glasses, protective clothing, and respirators are essential gear for any auto body repair shop conducting plasma cutting operations. These protect against flying debris, intense light, and potential fumes from heated materials.

Furthermore, proper ventilation is crucial in maintaining a safe workspace during plasma cutting collision repair. Auto repair services that incorporate this technology should ensure adequate exhaust systems and local exhaust vents to remove any harmful gases or vapors generated. Regular maintenance checks on equipment and thorough cleaning of work areas also contribute to minimizing risks associated with plasma cutting, making it a reliable method for vehicle body repair while prioritizing the well-being of employees and the environment.

Plasma cutting collision repair has emerged as a game-changer in the automotive industry, offering numerous advantages over traditional methods. By understanding the technology and implementing best practices, shops can enhance efficiency, reduce material waste, and ensure high-quality repairs. The benefits, from faster processing times to improved precision, make plasma cutting an essential tool for modern collision repair shops looking to stay competitive and meet customer expectations.