Auto body shops tackle post-collision repairs with a focus on minimizing heat damage alongside restoring vehicles to pre-accident condition. They employ advanced technologies like climate control rooms, specialized equipment, and skilled technicians to prevent invisible heat damage during welding, painting, and drying. Balancing heat application ensures structural integrity and aesthetic appeal, preserving vehicle value. Using controlled cooling, heat-resistant materials, and proper preparation reduces heat damage risk, protecting customer satisfaction and vehicle value post-incidents like fender benders or tire services.

In the realm of auto body repair, heat damage poses a significant risk, potentially leading to unsightly and costly rework. Understanding the intricacies of heat damage is paramount for shops aiming to deliver high-quality repairs. This article delves into the strategies and techniques employed by forward-thinking workshops to mitigate heat-related damage during auto body repair work. From recognizing risk factors to embracing advanced cooling methods, these measures ensure secure and cooler repair processes, safeguarding vehicles from future heat damage.

- Understanding Heat Damage Risks in Auto Body Repairs

- Essential Precautions to Mitigate Heat-Related Damage

- Advanced Techniques for Secure and Cooler Repair Processes

Understanding Heat Damage Risks in Auto Body Repairs

In the chaotic aftermath of a collision, auto body repair shops face a multifaceted challenge—not only to restore vehicles to their pre-accident condition but also to mitigate potential heat damage risks. Heat damage, often invisible yet significant, can occur during various stages of the repair process, from welding and painting to drying and curing. In a vehicle body shop, especially one offering collision repair services or frame straightening, understanding these risks is paramount for ensuring both structural integrity and aesthetic appeal.

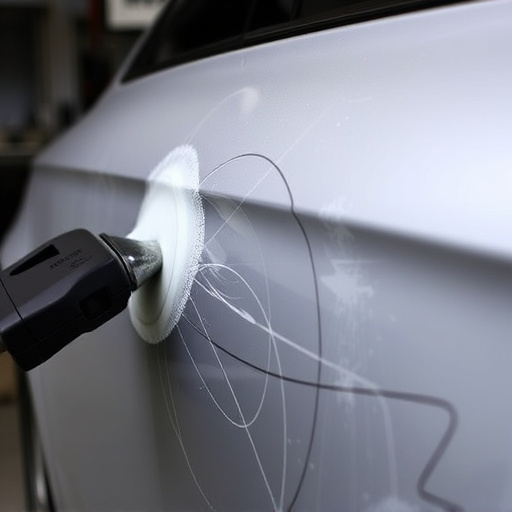

Shops employ a multitude of strategies to prevent heat damage auto body repairs. Advanced technologies like controlled climate rooms help maintain optimal temperatures during the painting process, preventing warping or blisters. Heat-resistant materials and specialized equipment are utilized in areas prone to high temperatures during frame straightening, minimizing the risk of damage to delicate parts. Moreover, experienced technicians are trained to balance heat application with precision, ensuring that every repair is not just functional but also visually seamless, preserving the vehicle’s original aesthetic and value.

Essential Precautions to Mitigate Heat-Related Damage

Preventing heat-related damage during auto body repair is paramount to ensure the longevity and aesthetic appeal of vehicles. Beyond utilizing specialized equipment with temperature control settings, shops must implement essential precautions. This includes strategically placing heat lamps or heaters away from sensitive areas, like painted surfaces or electronic components. Proper ventilation systems are also crucial to dissipate heat buildup and prevent warping or blisters in freshly repaired panels.

Furthermore, proper surface preparation before heating is vital. Technicians should carefully inspect and clean the area to be heated, removing any debris or contaminants that could lead to uneven heating or discoloration. By adhering to these practices, auto body repair shops can significantly reduce the risk of heat damage, ensuring customer satisfaction and maintaining the vehicle’s overall value during repairs, even after incidents like fender benders or tire services.

Advanced Techniques for Secure and Cooler Repair Processes

Advanced Techniques for Secure and Cooler Repair Processes

In the realm of auto body repair, protecting against heat damage is paramount, especially during the warmer months. Modern shops employ innovative strategies to ensure a cooler and more secure repair environment. One such technique involves utilizing advanced cooling systems that maintain optimal temperatures throughout the repair process. These systems prevent excessive heat buildup around sensitive components, like paint jobs and electronics, thus minimizing the risk of heat damage.

Moreover, skilled technicians adopt specialized tools and materials designed for high-temperature applications. This includes using heat-resistant adhesives and coatings, which not only withstand extreme temperatures but also contribute to a more efficient repair. By combining these advanced techniques with meticulous attention to detail, automotive repair services offer superior protection against heat damage, ensuring that vehicles are restored to their pre-incident condition while preserving the integrity of every part involved, including car dent removal when necessary.

In light of the above discussions, it’s clear that understanding and mitigating heat damage during auto body repairs is crucial for ensuring vehicle longevity and quality craftsmanship. By implementing essential precautions and adopting advanced techniques, shops can significantly reduce the risks associated with heat-related damage. These measures not only protect the integrity of the repair but also contribute to safer working conditions for technicians. In the context of modern automotive industry standards, these strategies are indispensable for maintaining high-quality repairs and customer satisfaction in the face of increasing heat damage auto body repair challenges.