The frame machine repair industry is undergoing a transformation due to rising costs driven by global supply chain disruptions, post-pandemic manufacturing challenges, and high demand for advanced services. Increased prices for key components and specialized equipment impact profitability. Collision centers adopt advanced technologies for precision and safety, but these add to customer costs. Complex vehicle designs require continuous frame machine upgrades. Urban areas face higher labor and material costs, and a shortage of skilled technicians drives up repair expenses. Shops combat rising costs with advanced technician training and digital tools, improving efficiency and competitiveness while maintaining high-quality repairs.

In recent years, frame machine repair costs have skyrocketed across the industry, posing significant challenges for auto shops and vehicle owners alike. This article delves into the factors driving these rising expenses, analyzing the current landscape of frame machine repair and exploring industry trends. We also offer practical strategies to help mitigate the impact of these cost hikes, providing insights that can benefit both professionals and consumers in navigating this evolving sector.

- Rising Costs: The Current Landscape of Frame Machine Repair

- Industry Trends: Factors Driving Increased Repair Expenses

- Strategies for Mitigating Frame Machine Repair Cost Hikes

Rising Costs: The Current Landscape of Frame Machine Repair

The landscape of frame machine repair is undergoing a significant shift as rising costs impact the entire industry. Key components and specialized equipment used in repairs have seen substantial price hikes, affecting profitability for many collision centers and auto repair shops. This trend is largely attributed to global supply chain disruptions, especially following the pandemic’s impact on manufacturing and logistics.

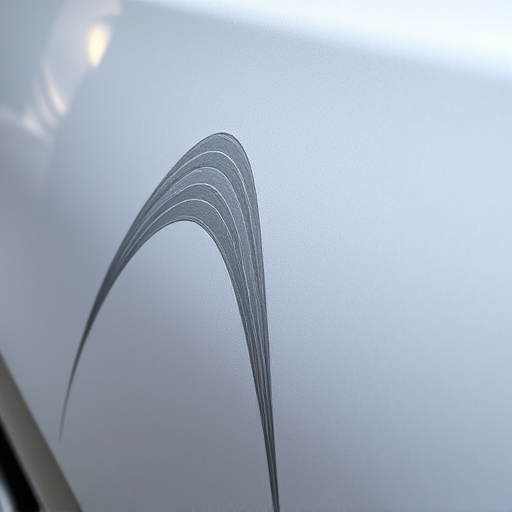

Additionally, the increasing demand for complex repairs, such as fender repair and car dent removal, has put further strain on resources. As consumers continue to prioritize vehicle aesthetics and safety, collision centers are investing in advanced technologies for precise frame alignment and structural integrity checks. These investments, while necessary for high-quality repairs, contribute to the rising costs that shops must pass on to customers.

Industry Trends: Factors Driving Increased Repair Expenses

In recent years, the landscape of frame machine repair has undergone a significant transformation, with costs rising across the industry. Several factors are driving this trend, including advancements in technology and an increased demand for specialized services, particularly in the realm of luxury vehicle repair. As vehicles become more complex, frame machines require ongoing upgrades to meet modern standards, enhancing precision and safety during the repair process.

Moreover, the rise in car collision repairs has put a strain on resources, leading to higher labor and material costs. This is especially noticeable in bustling metropolitan areas where accident rates are higher. Additionally, the scarcity of skilled technicians contributes to the overall increase in repair expenses, as shops struggle to keep up with the growing need for expert services, including those for sophisticated autobody repairs.

Strategies for Mitigating Frame Machine Repair Cost Hikes

To mitigate the rising costs of frame machine repairs across the industry, many auto shops are adopting innovative strategies. One effective approach is to invest in advanced training for technicians, ensuring they stay up-to-date with the latest technologies and techniques in frame repair. This specialized knowledge can help streamline the process, reduce labor costs, and improve overall efficiency.

Additionally, integrating digital tools and software into frame machine repair processes has proven beneficial. These solutions enable precise measurements, enhance communication between technicians, and provide detailed records of repairs. By implementing these strategies, collision repair centers and car restoration shops not only keep up with market demands but also effectively manage rising operational costs, ensuring they remain competitive in the industry while providing high-quality vehicle repair services.

As the frame machine repair industry faces escalating costs, understanding the driving trends and implementing strategic solutions is crucial. By recognizing the impact of technological advancements, material price fluctuations, and labor shortages on repair expenses, businesses can proactively mitigate these challenges. Adopting innovative techniques, investing in training, and exploring alternative sourcing strategies are key to navigating this evolving landscape. Staying agile and informed will enable frame machine repair specialists to offer competitive services while managing rising costs, ultimately ensuring long-term sustainability within the industry.