Laser alignment revolutionizes collision repair by offering precise, non-invasive measurements for auto glass replacement and component adjustments. It exceeds OEM standards, enhances vehicle safety and performance, saves time, resources, and streamlines processes, as proven in successful case studies involving bumper repairs and paintless dent correction.

Laser alignment is a game-changer in meeting Original Equipment Manufacturer (OEM) repair specifications. This precise, non-destructive testing method utilizes advanced technology to ensure critical components are aligned perfectly, minimizing collision risks and maximizing performance. By delving into the world of laser alignment, we explore how it enhances OEM standards, offers successful case studies, and revolutionizes the repair process for a wide range of industries.

- Understanding Laser Alignment Technology for Precision Repairs

- Enhancing OEM Specifications with Non-Destructive Testing

- Case Studies: Success Stories of Laser Alignment in Action

Understanding Laser Alignment Technology for Precision Repairs

Laser alignment technology has revolutionized precision repairs in the automotive industry, particularly for Original Equipment Manufacturer (OEM) standards. This advanced system is designed to ensure exacting measurements and adjustments, minimizing errors that could compromise safety and performance. By employing lasers, collision repair professionals can achieve remarkable accuracy when realigning components like chassis, panels, and frames.

This technology goes beyond traditional methods by offering a non-invasive approach, preserving the integrity of the vehicle’s structure. Moreover, laser alignment systems provide detailed data on misalignments, enabling technicians in an automotive body shop or car repair shop to make informed decisions for meticulous auto glass replacement or other intricate repairs. Such precision not only meets OEM specifications but also ensures the longevity and safety of vehicles undergoing restoration.

Enhancing OEM Specifications with Non-Destructive Testing

In today’s competitive automotive industry, Original Equipment Manufacturer (OEM) specifications are more stringent than ever. To meet these rigorous standards, auto body shops and tire services are turning to non-destructive testing methods like laser alignment. This advanced technology enables technicians to precisely measure and adjust various components of a vehicle without causing damage, ensuring that every repair aligns perfectly with OEM guidelines.

Laser alignment plays a pivotal role in achieving flawless results for car scratch repair and other intricate auto body shop tasks. By detecting even the subtlest misalignments, it helps address issues like tire services that are out of spec, enhancing overall vehicle performance and safety. This non-destructive approach not only saves time and resources but also ensures that every repaired vehicle leaves the shop meeting or exceeding OEM expectations.

Case Studies: Success Stories of Laser Alignment in Action

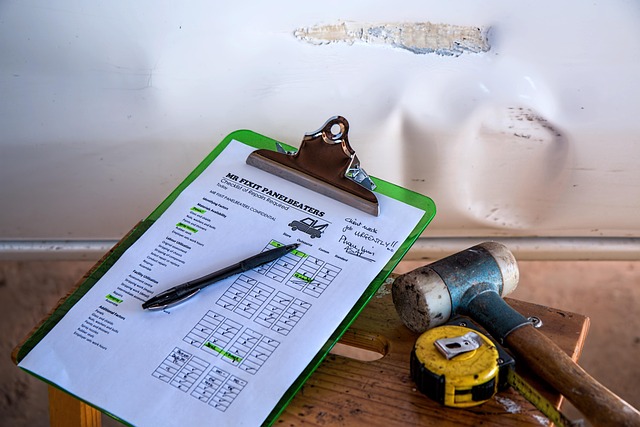

Laser alignment has proven its worth in numerous case studies, showcasing its ability to deliver precise results and meet OEM repair specifications. One notable success story involves a leading automotive manufacturer experiencing challenges with bumper repairs. By utilizing laser alignment technology, they were able to achieve remarkable accuracy in realigning damaged components, resulting in superior-quality vehicle repairs that met their stringent standards.

Another compelling example highlights the benefits of laser alignment in paintless dent repair. A specialized auto body shop encountered a complex case of multiple dents on a vehicle’s panel. With laser guidance, technicians were able to precisely locate and correct each dent, ensuring a flawless finish without the need for extensive repainting. This not only saved time and resources but also demonstrated the versatility and effectiveness of laser alignment in modern vehicle repair processes.

Laser alignment technology has proven its worth as a game-changer in the automotive repair industry, enabling technicians to meet and even exceed Original Equipment Manufacturer (OEM) specifications. By utilizing non-destructive testing methods, such as laser alignment, professionals can achieve precise repairs, ensuring vehicles return to their pre-collision state. The case studies presented demonstrate that laser alignment is not just a tool but a strategic approach that fosters success, enhances safety, and preserves the integrity of vehicles post-collision.