Digital frame measuring software revolutionizes car paint services and autobody repairs by eliminating manual calculations and physical templates, offering accurate measurements with a few clicks. This technology streamlines processes, ensures consistent results, and reduces time and resources compared to traditional methods. Choosing the right hardware and software involves understanding requirements like accuracy, object size, and surface complexity. Integrating digital frame measuring solutions can enhance Mercedes Benz collision repair, balancing initial costs with long-term cost savings and workflow streamlining.

In today’s digital age, accurate frame measurement is essential for various applications, from graphic design to construction. This article delves into the world of digital frame measuring tools, specifically comparing software and hardware options. We explore popular software choices, dissecting their features and limitations, while also understanding the underlying hardware requirements. By analyzing accuracy, cost-effectiveness, and performance, readers will gain insights to make informed decisions for their specific needs in the realm of digital frame measuring.

- Exploring Digital Frame Measuring Software Options

- Understanding Hardware Requirements and Limitations

- Comparing Features, Accuracy, and Cost: A Comprehensive Look

Exploring Digital Frame Measuring Software Options

When it comes to digital frame measuring tools, software options offer a versatile and cost-effective solution for various industries, including automotive. Exploring digital frame measuring software allows professionals in car paint services and autobody repairs to streamline their processes efficiently. These software applications provide accurate measurements and precise digital representations of frames, enabling easy comparison and analysis.

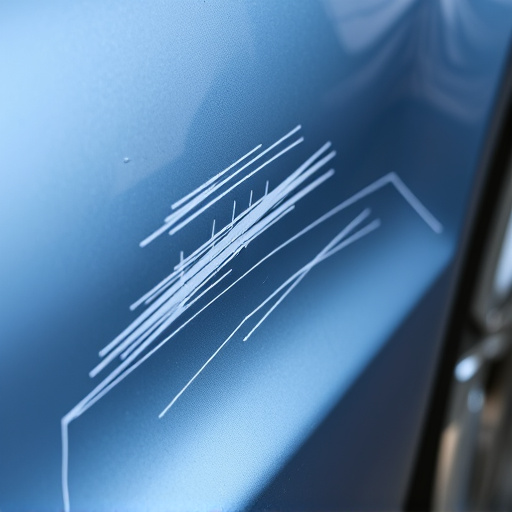

Unlike traditional methods, digital frame measuring software eliminates the need for manual calculations and physical templates. With just a few clicks, users can capture detailed measurements, ensuring consistent and repeatable results. Moreover, many software solutions offer additional features like 3D modeling and virtual prototyping, which are invaluable for auto repair shops looking to enhance their workflow. This technology is a game-changer, especially when compared to the time and resources required for traditional measuring methods, making it an attractive option for those seeking modern car paint services or autobody repairs.

Understanding Hardware Requirements and Limitations

When considering digital frame measuring tools, understanding the hardware requirements and limitations is paramount. These systems often rely on specialized equipment such as high-resolution cameras, laser scanners, or 3D imaging sensors to capture precise measurements of objects. The choice of hardware depends on factors like measurement accuracy needed, object size, surface complexity, and whether the digital frame measuring software will be used for simple inspections or complex repairs, akin to tasks seen in a collision repair shop or scratch repair service.

For instance, while a basic digital frame measuring setup might suffice for measuring smaller, simpler objects, such as frames or signs, more advanced hardware may be required for intricate or larger items like vehicle dent repair cases. The software itself should also align with these hardware capabilities, ensuring accurate and reliable measurements. Consider the resolution, processing power, and data storage needs of your chosen digital frame measuring solution to ensure it aligns with both your project scope and hardware limitations.

Comparing Features, Accuracy, and Cost: A Comprehensive Look

When comparing digital frame measuring software and hardware options for applications like Mercedes Benz collision repair or general vehicle repair services, a comprehensive analysis is crucial. Features, accuracy, and cost are key aspects to consider. Software solutions typically offer versatility with functions such as 3D modeling, virtual measuring, and design modifications, making them ideal for detailed tasks in dent removal and vehicle restoration. However, they may require substantial initial investment in hardware like high-resolution cameras and calibration equipment.

On the other hand, dedicated hardware systems, while often more expensive upfront, provide precise measurements with minimal setup. These systems are designed for speed and accuracy, making them suitable for high-volume workshops focusing on straightforward repairs. In terms of cost-effectiveness per measurement, software can be competitive once integrated into existing workflows, especially when considering the potential for streamlining multiple stages of vehicle repair services, akin to dent removal processes.

When it comes to digital frame measuring solutions, both software and hardware options offer unique advantages. Software applications provide flexibility and accessibility for quick measurements on various devices, while specialized hardware ensures precision and speed in professional settings. By understanding the features, accuracy, and cost of each option, businesses and individuals can make informed decisions to suit their specific needs in the digital frame measuring realm.