Understanding the frame and unibody structure is essential for ensuring vehicle safety during collision repair or restoration, as these components provide critical support and strength. Advanced measurement technologies like laser scanners and 3D software have revolutionized this process, offering unprecedented accuracy and efficiency compared to manual methods. Precise measurements are vital for adhering to industry standards, optimizing vehicle design for better impact protection, and facilitating efficient, safe, and cost-effective car repair services, thereby enhancing overall structural safety verification.

In the realm of structural safety verification, understanding the intricacies of a vehicle’s frame and unibody is paramount. These components form the foundation of structural integrity, crucial for passenger protection. Measuring frame and unibody dimensions accurately is not just a technical requirement but an essential step in ensuring compliance with safety standards. This article explores advanced techniques and tools used in precise measurements, delving into how they enhance overall structural design and contribute to safer vehicles.

- Understanding Frame and Unibody: The Foundation of Structural Integrity

- Measuring for Safety: Techniques and Tools for Accurate Verification

- Enhancing Safety Protocols: The Role of Precise Frame and Unibody Measurements in Structural Design and Compliance

Understanding Frame and Unibody: The Foundation of Structural Integrity

Understanding Frame and Unibody: The Foundation of Structural Integrity

In the realm of structural safety verification, whether for vehicles undergoing collision repair or in the process of auto body restoration, assessing the frame and unibody is paramount. These components form the backbone of a vehicle’s structure, ensuring its integrity during accidents and everyday driving. The frame, often considered the car’s skeleton, provides rigid support and connects various parts, while the unibody, a seamless monocoque design, offers superior strength and rigidity, enhancing overall structural safety.

Proper measurement and analysis of these elements are crucial for identifying potential weaknesses or damage following incidents like car scratch repair. By meticulously evaluating their dimensions, engineers can ensure that the vehicle retains its structural integrity, meeting safety standards and providing peace of mind for both manufacturers and owners alike during the structural safety verification process.

Measuring for Safety: Techniques and Tools for Accurate Verification

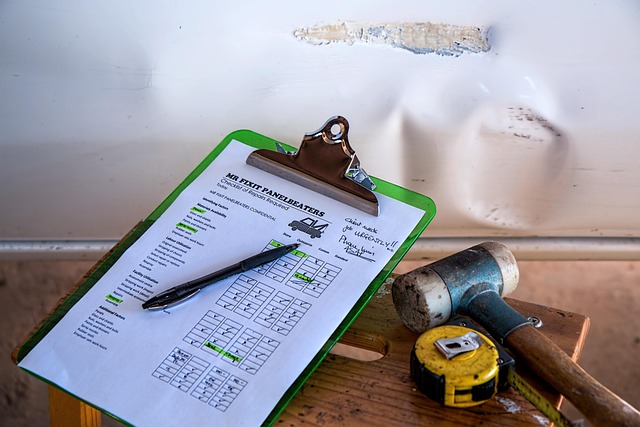

Measuring for safety is a critical aspect of structural safety verification, especially in the automotive industry where precision and integrity are paramount. Advanced techniques and tools have revolutionized how we approach frame and unibody measurements during car collision repair. Digital measuring systems, including laser scanners and 3D body measurement software, offer unprecedented accuracy and efficiency compared to traditional manual methods. These technologies capture intricate details of vehicle structures, enabling auto body shops to pinpoint precise dimensions, identify deviations, and ensure compliance with safety standards.

By employing these accurate verification methods, automotive collision repair specialists can confidently assess the structural integrity of frames and unibodies post-collision. This meticulous approach not only guarantees a safer driving experience but also facilitates more effective and efficient repairs, minimizing the time and cost associated with auto body shop operations.

Enhancing Safety Protocols: The Role of Precise Frame and Unibody Measurements in Structural Design and Compliance

In the realm of structural safety verification, precise measurements of a vehicle’s frame and unibody play a pivotal role in enhancing overall safety protocols. These critical dimensions ensure that the structure meets stringent industry standards, providing robust protection for occupants during collisions. Accurate data allows engineers to optimize designs, ensuring energy absorption and force distribution are maximized across various impact scenarios.

Furthermore, meticulous measurements facilitate effective troubleshooting during car repair services and auto bodywork processes. When issues arise, having detailed frame and unibody dimensions aids in identifying problems early on, streamlining repairs, and maintaining the structural integrity of vehicles. This meticulous approach, extending beyond routine vehicle paint repair, is essential for upholding safety standards and fostering confidence in the automotive industry.

Accurate measurement of frame and unibody dimensions is a cornerstone of effective structural safety verification. By employing advanced techniques and tools, engineers can ensure compliance with safety standards and enhance the overall integrity of structures. Precise frame and unibody measurements play a pivotal role in optimizing design, identifying potential weaknesses, and ensuring the longevity and safety of buildings—essential aspects for any successful structural safety verification process.