The post-repair inspection process is crucial for high-quality auto repair, ensuring structural integrity, road safety, and customer satisfaction. This meticulous evaluation includes visual examinations and specialized tool assessments of welds, frames, and panels, meeting industry standards and regulatory requirements. Effective post-repair inspections involve thoroughness, advanced tools, consistent checklists, and inspector training to guarantee reliable services, long-term vehicle safety, and performance for collision repair and car body restoration work.

In the realm of welding and frame repairs, a meticulous post-repair inspection process is paramount to ensure structural integrity and safety. This article delves into the critical aspects of this often overlooked yet vital step. Understanding why a thorough inspection matters, coupled with a structured guide, empowers professionals to deliver quality work. From preparation to final verification, this comprehensive overview outlines key considerations for an effective post-repair inspection process, ensuring peace of mind for both repairers and vehicle owners alike.

- Understanding the Importance of Post-Repair Inspection

- Step-by-Step Guide to a Comprehensive Post-Repair Inspection

- Key Considerations for Effective Post-Repair Inspection Process

Understanding the Importance of Post-Repair Inspection

A post-repair inspection is a vital step in any reputable auto repair service or automotive body shop’s process. It ensures that repairs are not only visually appealing but also structurally sound and safe for the road. This meticulous check involves examining every detail, from the quality of welds to the alignment of frames, to guarantee that the vehicle meets the highest standards. Such inspections are crucial in identifying any potential issues that might have been overlooked during the repair process, ensuring customer satisfaction, and fostering trust in the automotive body shop’s expertise.

This thorough evaluation is particularly important for complex frame repairs, which often require intricate welding techniques. Post-repair inspection allows auto repair professionals to verify the integrity of the structural components, ensuring they meet industry standards and regulatory requirements. By implementing a robust post-repair inspection process, automotive repair shops can maintain their reputation, provide reliable services, and ensure the long-term safety and performance of vehicles they service.

Step-by-Step Guide to a Comprehensive Post-Repair Inspection

A meticulous post-repair inspection process is paramount for ensuring top-notch vehicle repair services. It involves a step-by-step comprehensive evaluation to guarantee that all damage, including intricate dent removal, has been effectively remedied. The journey begins with a visual examination of the entire vehicle, meticulously scrutinizing every angle and contour to identify any residual marks or discrepancies. This initial inspection sets the foundation for subsequent, more detailed checks.

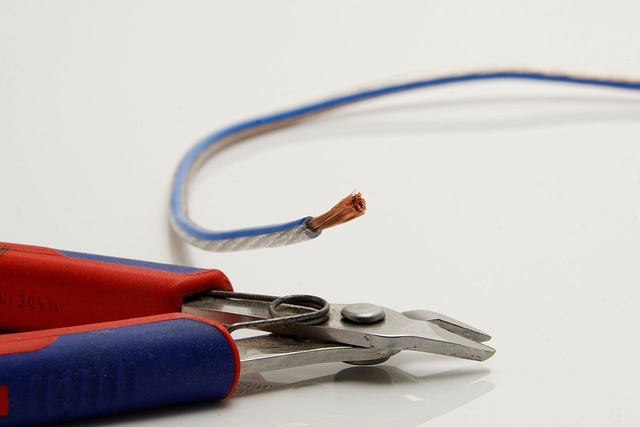

The process then delves into specific areas like welds, frames, and panels, employing specialized tools to assess structural integrity and alignment. This includes verifying that all repairs adhere to industry standards and manufacturer specifications. Any deviations or areas of concern are documented for further analysis. The final step involves a road test to ensure the vehicle handles seamlessly and all systems operate optimally after the car damage repair.

Key Considerations for Effective Post-Repair Inspection Process

The post-repair inspection process is a critical step in ensuring the quality and safety of collision repair and car body restoration work performed in an automotive body shop. Several key considerations play a pivotal role in making this process effective. First, thoroughness is paramount; inspectors should meticulously examine every aspect of the repaired area, including the welds, frame alignment, and paint finish, to ensure they meet industry standards and customer expectations.

Second, using the right tools and equipment for inspection is essential. This includes advanced technology like laser measurement devices, 3D scanning systems, and high-resolution cameras that can detect even minute discrepancies. Additionally, maintaining a consistent and standardized inspection checklist across all repair projects helps in streamlining the process, making it easier to identify potential issues early on. Moreover, continuous training for inspectors on the latest industry practices and safety protocols guarantees a comprehensive evaluation of each repair job.

The post-repair inspection process is a vital step in ensuring the quality and safety of welding and frame repairs. By meticulously following a structured approach, as outlined in this guide, repair professionals can guarantee that any work meets the highest standards. This process not only safeguards against potential issues but also fosters trust among customers, demonstrating the industry’s commitment to excellence. Implement these practices to streamline your post-repair inspection routine and maintain consistent, reliable results.