Quality control inspections are essential for maintaining product excellence, customer satisfaction, and vehicle safety across industries, especially automotive manufacturing and repair. Safety verification is a critical component of these inspections, ensuring products meet standards, preventing failures, and fostering trust. Effective practices involve training inspectors, understanding industry standards, and utilizing advanced technologies to adapt across industries, prioritizing precision and safety in processes like auto body painting.

In today’s competitive market, ensuring product excellence through rigorous quality control inspections is paramount. This article delves into the integral aspect of safety verification, a critical component within every quality control inspection process. Understanding these inspections forms the foundation for delivering superior products to consumers. By focusing on safety verification, manufacturers can safeguard end-users and uphold product reliability. We explore effective strategies to implement these practices, ensuring every step aligns with consumer protection.

- Understanding Quality Control Inspections: The Foundation of Product Excellence

- The Role of Safety Verification: Ensuring Consumer Protection and Product Reliability

- Implementing Effective Safety Verification Practices: Strategies for Every Inspection Process

Understanding Quality Control Inspections: The Foundation of Product Excellence

Quality control inspections are a cornerstone in ensuring product excellence across various industries, especially automotive manufacturing and repair. These meticulous processes involve a comprehensive evaluation of products or services to identify any deviations from established standards or specifications. Every aspect is scrutinized to guarantee that what leaves the production line or workshop meets the required quality criteria. This involves everything from checking physical attributes like dimensions and finish to functional testing to ensure performance aligns with design intent.

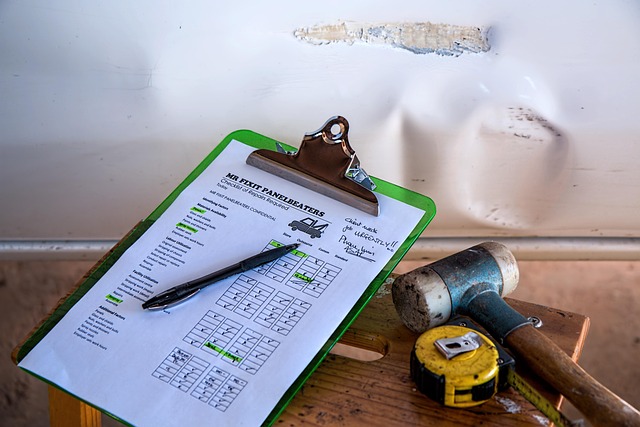

In the context of auto repair, a quality control inspection goes beyond merely checking if a car’s dent removal was effective; it verifies every step of the collision center’s work, from initial assessment to final reconditioning. This ensures that auto repair services are not just executed but also delivered at a consistent, high standard. Effective quality control inspections are crucial for maintaining customer satisfaction and building trust in services like dent removal and other auto repair processes, ultimately contributing to the overall safety and reliability of vehicles on the road.

The Role of Safety Verification: Ensuring Consumer Protection and Product Reliability

Safety verification plays a pivotal role within every quality control inspection, serving as the safeguard between consumers and potential hazards. It’s not just about checking if a product functions; it’s about ensuring that said product is safe to use. In industries such as automotive, where vehicle bodywork often undergoes rigorous repairs after car collisions, safety verification becomes an indispensable step in the quality control process.

This meticulous verification goes beyond visual inspections and material checks. It involves stringent testing and evaluation to confirm that every component meets safety standards, functioning optimally and preventing failures that could lead to accidents or injuries. By integrating this vital step into standard operating procedures, manufacturers and repair shops ensure consumer protection and product reliability, fostering trust among their clientele.

Implementing Effective Safety Verification Practices: Strategies for Every Inspection Process

In the realm of quality control inspections, safety verification is an indispensable component that ensures not just product excellence but also worker protection and environmental sustainability. Effective safety verification practices transform every inspection into a comprehensive process that goes beyond surface-level checks. It involves training inspectors to identify potential hazards, understanding industry standards, and employing advanced technologies for accurate assessments.

For auto repair services and car paint services, where precision and safety are paramount, implementing these strategies is crucial. Auto body painting processes, for instance, require meticulous attention to detail not just in aesthetics but also in the handling of hazardous chemicals and equipment. Safety verification ensures that every step, from preparation to application and curing, adheres to strict protocols, minimizing risks and maximizing quality outcomes. These practices are adaptable to various industries, fostering a culture of safety and excellence in every quality control inspection.

Every successful quality control inspection hinges on integrating thorough safety verification, not just as an add-on but as a core component. By prioritizing consumer protection and product reliability through rigorous safety checks, manufacturers can ensure their products meet the highest standards. Implementing effective safety verification practices across every inspection process fosters a culture of excellence, ensuring that only safe and reliable goods reach the market. This holistic approach to quality control inspections is vital for maintaining customer trust and market competitiveness in today’s stringent regulatory environment.