Quality control inspections are vital for building and maintaining a solid reputation in precision-driven industries like automotive repair and restoration. These meticulous processes involve comprehensive evaluations of materials, craftsmanship, and design specifications at every stage of production. For auto painting services, inspectors assess preparation, priming, layering, and final coats to ensure color accuracy, surface smoothness, and durability. Rigorous quality control inspections foster consumer trust, guarantee high-quality products or services, and differentiate reputable shops in competitive markets, ultimately driving repeat business and positive word-of-mouth referrals.

In today’s competitive market, a shop’s reputation is built on rigorous quality control inspections. These practices ensure product excellence, fostering customer trust and driving business growth. Understanding the importance of thorough inspections, implementing stringent standards, and measuring their impact on both brand perception and client satisfaction is paramount for success. This article explores these key aspects, delving into how quality control inspections serve as the backbone of a reputable shopping experience.

- Understanding Quality Control Inspections: The Backbone of Reputable Shopping

- Implementing Rigorous Practices: Ensuring Product Excellence and Customer Trust

- Measuring Success: The Impact of Quality Control on Business Reputation and Customer Satisfaction

Understanding Quality Control Inspections: The Backbone of Reputable Shopping

Quality control inspections are a meticulous process that serves as the cornerstone for building and maintaining a solid shopping reputation. These inspections go beyond basic checks to ensure every product meets stringent standards. It involves a comprehensive evaluation of materials, craftsmanship, and adherence to design specifications at various stages of production. For industries like automotive repair and restoration, such as mercedes benz repair or car body restoration, where precision is paramount, quality control inspections are vital.

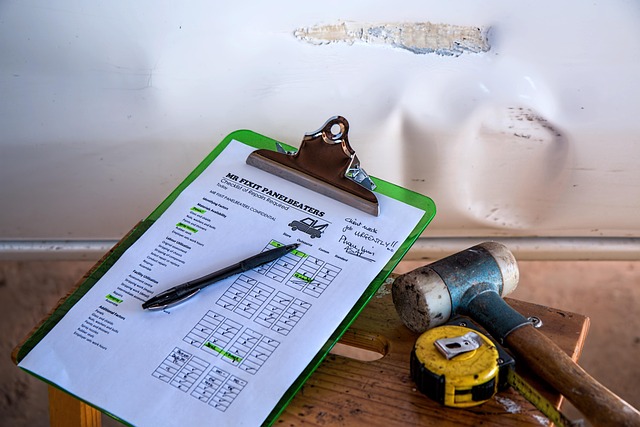

In the context of auto painting, for instance, inspectors scrutinize not just the final coat but also the preparation, priming, and layering processes, ensuring color accuracy, surface smoothness, and durability. By implementing rigorous quality control inspection practices, businesses foster trust among consumers, guaranteeing that products or services delivered are of the highest caliber. This commitment to excellence is what sets reputable shops apart in a competitive market.

Implementing Rigorous Practices: Ensuring Product Excellence and Customer Trust

In today’s competitive market, building a solid reputation requires more than just offering products or services; it hinges on meticulous quality control inspection practices. By implementing rigorous standards, businesses ensure that every item leaving their facilities meets the highest possible criteria. This commitment to excellence is pivotal in fostering customer trust and loyalty. When consumers know that a brand conducts thorough quality checks on its offerings—be it auto detailing, automotive collision repair, or dent removal services—they gain confidence in the product’s reliability and performance.

Such practices not only guarantee superior products but also set a brand apart from its competitors. In industries where precision is paramount, like automotive repairs, maintaining strict quality control inspection standards becomes even more critical. It ensures that every detail is addressed, every dent removed, and every repair executed with meticulous care. This dedication to meticulousness reflects positively on the brand’s reputation, encouraging repeat business and positive word-of-mouth referrals.

Measuring Success: The Impact of Quality Control on Business Reputation and Customer Satisfaction

The success of any business, especially those offering specialized services like body shop services, heavily relies on its ability to consistently deliver high-quality outcomes. Quality control inspection plays a pivotal role in achieving this goal. It acts as a vigilant guard, ensuring every product or service rendered meets stringent standards and aligns with customer expectations. By meticulously scrutinizing each aspect of the work, from material selection to final assembly, businesses can identify and rectify imperfections before they reach the client.

This meticulous process has profound implications for both business reputation and customer satisfaction. Positive experiences stemming from rigorous quality control in body shop services or auto body restoration, for instance, foster trust and encourage repeat business. Conversely, poor quality control can lead to damaging reviews, negative word-of-mouth, and a tarnished brand image. Therefore, investing in robust quality control inspection practices is not merely an option but a strategic necessity for maintaining a competitive edge and ensuring long-term success in any industry, be it vehicle body repair or intricate auto body restoration projects.

Quality control inspections are the unsung heroes of reputable shopping, ensuring product excellence and fostering customer trust. By implementing rigorous practices, businesses can significantly enhance their reputation and drive customer satisfaction. These inspections serve as a crucial metric for gauging product quality, identifying areas for improvement, and ultimately, navigating the competitive market with confidence.