Tesla structural aluminum repair demands specialized tools due to aluminum's unique properties—lightweight yet robust with distinct bonding. Advanced equipment like welding machines, hydraulic presses, and CAD software ensure precise measurements, cuts, and fusions, preserving vehicles' structural integrity. State-of-the-art paint services match original factory finishes. Strategic use of specialized gear guarantees efficient, quality repairs for Tesla vehicles, maintaining strength, performance, and value.

Tesla vehicles, renowned for their cutting-edge technology, come with unique challenges when it comes to repairs, especially structural aluminum repairs. This specialized task requires precision and the right equipment due to the car’s innovative design. In this article, we explore the specialized tools needed for Tesla structural aluminum repairs, delve into the challenges that arise during these repairs, and stress the importance of high-quality equipment in ensuring top-notch workmanship.

- Specialized Tools for Tesla Aluminum Repairs

- Challenges in Structural Aluminum Repair

- Ensuring Quality: The Right Equipment Matters

Specialized Tools for Tesla Aluminum Repairs

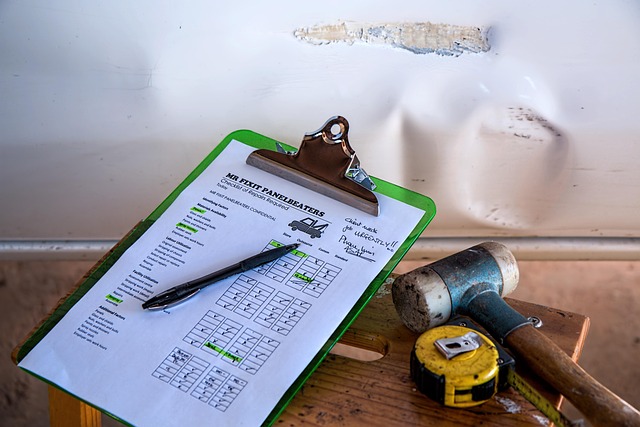

When it comes to Tesla structural aluminum repair, specialized tools are essential for achieving precision and quality results. Unlike conventional metal repairs, working with aluminum requires specific equipment designed to handle its unique properties. This includes lightweight yet robust materials and a distinct bonding process. Professionals in the auto repair services industry invest in advanced tools like specialized welding machines, hydraulic presses, and computer-aided design (CAD) software tailored for aluminum bodywork.

These tools enable precise measurements, accurate cuts, and seamless fusions, ensuring the structural integrity of the vehicle. Moreover, car paint services that specialize in Tesla repairs often employ state-of-the-art equipment to match the original factory finish perfectly. This meticulous attention to detail is crucial when dealing with Tesla’s sleek and modern designs, where any imperfection can be readily noticeable. Specialized tools not only streamline the collision repair process but also guarantee a visually appealing and long-lasting repair for Tesla owners.

Challenges in Structural Aluminum Repair

When it comes to Tesla structural aluminum repair, several unique challenges set this apart from standard car repair services. The intricate and precision-engineered nature of Tesla vehicles means that even minor accidents can result in complex damage to their lightweight yet robust aluminum bodies. Unlike traditional vehicle collision repair, where steel panels are commonly replaced, structural aluminum repair requires specialized knowledge and equipment due to the material’s unique properties.

Aluminum has distinct characteristics, such as being corrosion-resistant and lighter than steel, but it also presents challenges like reduced strength in certain directions and a tendency to deform under high impact. Repairing these vehicles necessitates advanced techniques like precision welding, specialized tools for measuring and aligning components, and an understanding of computer-aided design (CAD) to ensure accurate repairs that maintain the structural integrity of the vehicle—a key consideration in Mercedes Benz collision repair as well.

Ensuring Quality: The Right Equipment Matters

Ensuring quality in Tesla structural aluminum repair is paramount due to the unique and advanced nature of these vehicles. The right equipment plays a pivotal role in achieving precise and lasting results, especially when dealing with intricate components like aluminum bodies. Specialized tools designed for Tesla repairs allow technicians to access hard-to-reach areas, ensuring every dent or damage is accurately assessed and addressed.

Investing in top-tier equipment for car dent removal and automotive collision repair specifically tailored for Teslas guarantees that the vehicle’s structural integrity remains intact. These advanced tools enable efficient removal of dents without compromising the aluminum’s strength or aesthetics, which is crucial for maintaining the overall performance and value of the vehicle. With the right gear, mechanics can efficiently navigate complex repairs, making Tesla structural aluminum repair a seamless and reliable process.

When it comes to Tesla structural aluminum repair, specialized equipment and expertise are paramount. The unique challenges posed by this process demand precise tools that can handle intricate work with durability. Investing in the right gear ensures not only high-quality repairs but also preserves the vehicle’s integrity and aesthetic appeal. For those seeking Tesla structural aluminum repair, understanding these requirements is key to achieving superior outcomes.