In the manufacturing sector, hazardous waste management is crucial to prevent environmental damage and worker/community health issues from improper disposal of toxic chemicals and by-products. Auto repair facilities, for example, require robust strategies involving eco-friendly practices, specialized technologies, regulatory adherence, comprehensive planning, and staff training to handle solvents and paints safely. Implementing sustainable hazardous waste management minimizes pollution, promotes resource reuse, complies with regulations, and fosters environmental safety and sustainability in manufacturing.

Hazardous waste management is an indispensable practice within manufacturing, addressing the critical need to mitigate environmental impact and ensure worker safety. This article delves into the essential role of effective hazardous waste management in manufacturing. We explore the nature of hazardous materials, their potential impacts, and dissect the strategic strategies for implementation. Understanding these elements is vital for embracing sustainable practices and fostering a responsible industrial landscape.

Key focus areas include: understanding hazardous waste, its impact on manufacturing; exploring the benefits of efficient management; and implementing sustainable solutions to minimize risks and environmental harm.

- Understanding Hazardous Waste and Its Impact in Manufacturing

- The Role of Effective Hazardous Waste Management

- Strategies for Implementing Sustainable Practices

Understanding Hazardous Waste and Its Impact in Manufacturing

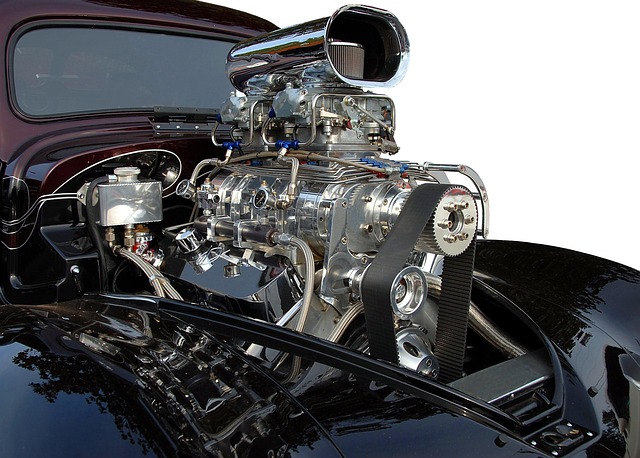

In the manufacturing sector, hazardous waste is a significant concern that demands careful consideration and efficient management strategies. It encompasses a wide range of materials, from toxic chemicals to harmful by-products and residuals generated during various industrial processes. These wastes can have severe environmental and health implications if not handled properly. In manufacturing, where complex operations involve the use of numerous chemicals and machines, understanding the potential risks associated with hazardous waste is paramount. For instance, auto frame repair and auto collision repair facilities often deal with toxic substances like solvents and paints, which, when improperly disposed of, can contaminate soil, water bodies, and air.

The impact of inadequate hazardous waste management in manufacturing settings can be devastating. It not only poses risks to workers’ health but also threatens nearby communities and ecosystems. Leaks or spills of hazardous materials can lead to long-term environmental damage, affecting local flora and fauna. Moreover, improper disposal practices can contribute to air pollution, respiratory issues, and even cancer among residents living near industrial areas. Therefore, implementing robust hazardous waste management systems is crucial for manufacturers to ensure the well-being of their employees, surrounding communities, and the environment at large. This includes adopting eco-friendly practices, utilizing specialized waste treatment technologies, and adhering to strict regulatory guidelines to mitigate risks associated with hazardous waste generation and disposal.

The Role of Effective Hazardous Waste Management

Effective hazardous waste management plays a pivotal role in the manufacturing sector, ensuring the safety and sustainability of operations. It involves the careful handling, treatment, storage, and disposal of potentially harmful substances generated during various industrial processes. By implementing robust hazardous waste management strategies, manufacturers can significantly reduce environmental pollution, mitigate health risks for employees and surrounding communities, and comply with stringent regulatory frameworks.

This process is especially crucial in industries like auto body services and vehicle collision repair, where the handling of toxic chemicals, such as solvents and paints, is common. Proper management includes identifying hazardous materials, implementing appropriate containment measures, training staff on safe practices, and utilizing specialized equipment for treatment or recycling. It also involves regular monitoring and reporting to track waste generation and ensure responsible disposal, contributing to a cleaner and healthier environment while promoting the efficient use of resources in car body restoration processes.

Strategies for Implementing Sustainable Practices

Implementing sustainable practices in hazardous waste management is a multifaceted approach that begins with comprehensive planning. Manufacturing facilities should first conduct thorough assessments to identify all potential sources of hazardous materials, including those from processes like vehicle paint repair and car restoration in automotive body shops. Once identified, these areas require specialized handling and disposal methods. Engaging experts in hazardous waste management can provide valuable insights into the most efficient and eco-friendly solutions.

Strategic implementation involves adopting circular economy principles, where waste is minimized, and resources are reused or recycled. For instance, implementing closed-loop systems for paint recycling in automotive body shops not only reduces hazardous waste but also offers economic benefits. Additionally, training employees on proper waste segregation and disposal techniques ensures compliance with environmental regulations and fosters a culture of sustainability within the manufacturing sector.

Hazardous waste management is not just a regulatory requirement but a crucial strategy for manufacturing industries to thrive sustainably. By implementing effective waste management practices, manufacturers can minimize environmental impact, protect worker health and safety, and even reduce costs in the long run. It’s a vital step towards creating a greener, more responsible future for the industry and our planet. Effective hazardous waste management is a game-changer that fosters a safer, healthier, and more eco-conscious manufacturing landscape.