Color spectrophotometers have become essential tools in modern auto body shops, revolutionizing car repair with precise color matching. These advanced devices measure light absorption at specific wavelengths to accurately capture an object's true color, ensuring exact replication of original vehicle finishes. Beyond paint matching, spectrophotometers are used for quality control in various processes, including finish inspection and tire composition analysis. Their use brings significant benefits, enhancing repair quality and efficiency by adhering to factory specifications, minimizing waste, reducing turnaround times, and boosting customer satisfaction with impeccable results. As a game-changer in collision repair, the color spectrophotometer is transforming the auto body shop industry.

In modern auto body shops, the color spectrophotometer has become an indispensable tool for achieving precise and flawless paint jobs. This advanced technology goes beyond traditional matching methods by providing an accurate measurement of a vehicle’s color, ensuring exact replicas regardless of the original shade’s complexity. By employing color spectrophotometers, shops can significantly enhance productivity, reduce waste, and deliver superior customer satisfaction through consistent, high-quality finishes.

- Understanding Color Spectrophotometers: Their Role in Auto Body Repair

- Advantages of Using Color Spectrophotometers in Body Shops

- How Color Spectrophotometry Enhances Paint Job Quality and Efficiency

Understanding Color Spectrophotometers: Their Role in Auto Body Repair

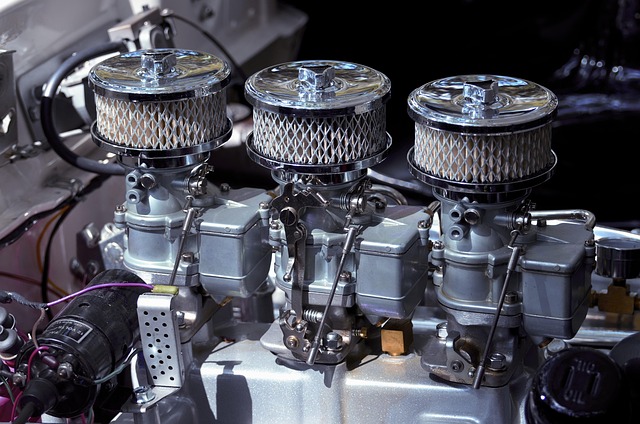

Color spectrophotometers have emerged as indispensable tools in modern auto body shops, revolutionizing the way professionals approach car body repair. These advanced devices play a pivotal role in ensuring precise color matching during restoration processes. By measuring and analyzing light absorption at specific wavelengths, spectrophotometers capture an object’s true color, making them invaluable for matching paints to the exact shade of the original vehicle finish.

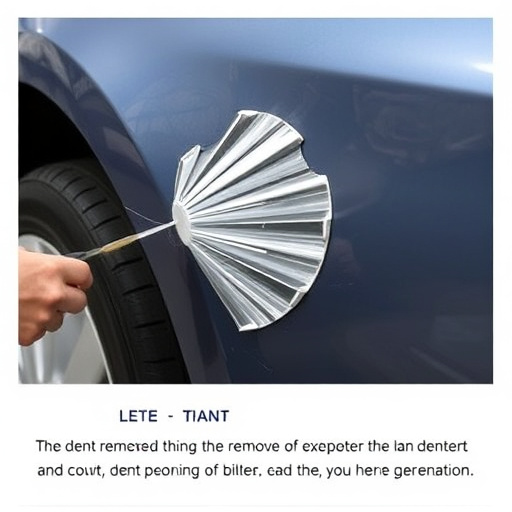

In the realm of auto body repair, achieving seamless color continuity is non-negotiable. Color spectrophotometers enable technicians to accurately assess and replicate colors, ensuring that repaired vehicles maintain their aesthetic integrity. Beyond paint matching, these instruments can also be employed for quality control in various processes, including inspecting finishes, monitoring paint thickness, and even analyzing the composition of tires (tire services) through their unique spectral signatures.

Advantages of Using Color Spectrophotometers in Body Shops

Using color spectrophotometers in modern auto body shops offers numerous advantages that enhance the quality and efficiency of repairs. These advanced tools allow for precise color matching, ensuring that vehicle paint jobs are not just visually appealing but also perfectly aligned with the original factory specifications. This accuracy is crucial in auto body painting and fender repair, where even minor variations can affect the overall aesthetics and resale value of a vehicle.

Furthermore, spectrophotometers streamline the process of vehicle dent repair by providing instant color readings and data, enabling technicians to make quick, informed decisions. This technology reduces waste, saves time, and minimizes the need for trial-and-error methods commonly used in traditional paint matching processes. As a result, auto body shops can offer faster turnaround times while maintaining high standards of craftsmanship.

How Color Spectrophotometry Enhances Paint Job Quality and Efficiency

Color spectrophotometry has transformed the paint job quality and efficiency in auto body shops. This advanced technology enables precise measurement and analysis of colors, ensuring that every repair matches the original vehicle finish perfectly. By taking spectral data, a color spectrophotometer captures the exact hue, shade, and tone, eliminating subjective human assessment.

This method enhances productivity by reducing the time spent on touch-ups and re-painting. It also minimizes waste, as accurate measurements lead to less excess paint usage. In addition, it improves customer satisfaction by delivering visually impeccable results that match the vehicle’s original aesthetics, making it an indispensable tool in modern collision repair and auto body shops.

Color spectrophotometers have become indispensable tools in modern auto body shops, offering unparalleled precision and efficiency in paint job quality. By precisely measuring and matching colors, these advanced devices ensure consistent, high-quality finishes that meet customer expectations. The advantages of color spectrophotometry are clear, from streamlined workflows to reduced waste and faster turnaround times. As the automotive industry continues to evolve, the color spectrophotometer stands as a standard for excellence in auto body repair.