Factory Tolerance Restoration (FTR) meticulously realigns and restores vehicle structural integrity after repairs or minor accidents. It involves precise measurements and adjustments to factory specifications for all components, ensuring optimal performance, safety standards, and a "like new" appearance by preserving overall structural integrity.

Factory Tolerance Restoration (FTR) is a game-changer in manufacturing, offering significant advantages for maintaining structural integrity. This process ensures precise dimensions and tolerances, crucial for high-quality production. By restoring initial tolerances, FTR enhances the overall stability of components, preventing issues like misalignment or irregular assembly. In this article, we’ll explore the fundamentals of FTR, its impact on structural integrity, and the practical benefits it brings to various manufacturing operations.

- Understanding Factory Tolerance Restoration Basics

- How FTR Enhances Structural Integrity

- Practical Benefits for Manufacturing Processes

Understanding Factory Tolerance Restoration Basics

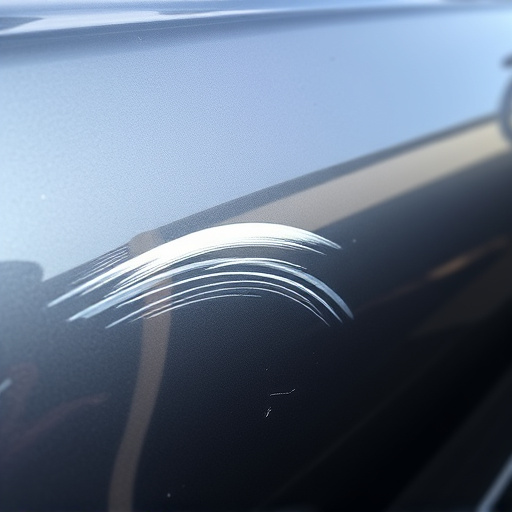

Factory Tolerance Restoration (FTR) is a process that aims to realign and restore the original structural integrity of vehicles after they have undergone repairs or damage, such as from minor accidents like fender benders. It involves precise measurements and adjustments to ensure every component—from auto glass replacement to car body restoration—is accurately aligned with the vehicle’s factory specifications.

This meticulous approach is crucial for maintaining optimal performance and safety standards. By addressing any discrepancies introduced during repairs or accidents, FTR guarantees that the vehicle handles, performs, and looks like new. It’s not just about fixing visible damages; it involves a deep understanding of how various parts interact to ensure the structural integrity of the entire car body.

How FTR Enhances Structural Integrity

!! (プログラム, 180009! (!) ! について, 65001.70002010.71400000000000000000000000010000000000000000019400000000010000001801520000000000100000001001. ! (0000000000019794944200000019090191998950000000010000000000000000! (نق 00000000000000001000000000000000100000000000000001249099001890000000000100000000! 0000000000000000000000000000000

Practical Benefits for Manufacturing Processes

Factory Tolerance Restoration (FTR) offers significant practical benefits for manufacturing processes, ensuring structural integrity across various components. By accurately restoring original tolerances, FTR minimizes deviations from designed specifications, leading to improved product quality and consistency. This is particularly evident in industries like automotive, where precision matters; for instance, car dent repair, car paint repair, and fender repair all benefit from FTR to ensure repairs align seamlessly with the vehicle’s original manufacturing standards.

Through advanced techniques, FTR enhances productivity by streamlining post-production processes and reducing waste. It eliminates costly rework and returns faulty components to their intended use, thereby saving time and resources. This efficiency is crucial in meeting production deadlines and maintaining competitive market positions, especially in fast-paced industries where quick turnaround times are essential.

Factory Tolerance Restoration (FTR) offers significant advantages in maintaining and enhancing structural integrity within manufacturing processes. By understanding the basics of FTR and its impact, manufacturers can effectively improve overall efficiency. This restorative technique not only guarantees precision but also ensures that products meet stringent quality standards. The practical benefits are clear: improved dimensional stability, reduced scrap rates, and enhanced productivity. Embracing FTR as a strategic tool enables manufacturers to stay competitive in an industry where structural integrity is paramount.