Infrared curing equipment revolutionizes automotive aftermarket services with its advanced technology, offering faster drying and curing times for coatings, adhesives, and sealants compared to traditional methods. Its precise, controlled heating ensures optimal curing conditions without damaging sensitive materials, benefiting dent repair by enabling quicker repairs while maintaining vehicle structure integrity and auto body painting by improving finish durability. Adopting this equipment in vehicle body shops significantly boosts productivity, reduces cycle times, optimizes operations, and enhances customer satisfaction. As a game-changer across various industries, including frame, paint, and dent repair, continuous technological advancements and automation will further elevate its role in workshop productivity and industrial innovation.

Infrared curing equipment has emerged as a game-changer in industrial settings, offering unprecedented control over drying and curing processes. This technology utilizes focused infrared radiation to swiftly heat materials, revolutionizing shop productivity. By understanding how these systems function and their unique advantages, businesses can harness their potential to streamline operations. From rapid drying times to improved material properties, infrared curing equipment promises significant time savings and enhanced efficiency, making it an essential consideration for modern workshops.

- Understanding Infrared Curing Equipment and Its Functionality

- The Impact on Shop Productivity: Advantages and Time Savings

- Optimizing Processes and Future Considerations for Enhanced Efficiency

Understanding Infrared Curing Equipment and Its Functionality

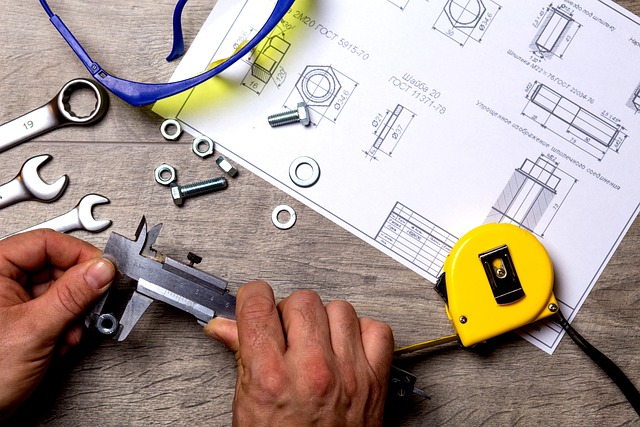

Infrared curing equipment represents a significant advancement in the realm of automotive aftermarket services, particularly for tasks such as car dent repair and auto body painting. This innovative technology utilizes focused infrared radiation to accelerate the drying and curing process of various coatings, adhesives, and sealants used in car bodywork. By emitting energy in the infrared spectrum, these machines efficiently heat the surface being treated, leading to faster cure times compared to conventional methods.

The functionality of infrared curing equipment lies in its ability to provide precise and controlled heating, ensuring optimal curing conditions without over-drying or damaging sensitive materials. This is especially beneficial for car dent repair, where quick and even heating can facilitate faster repairs while maintaining the integrity of the vehicle’s structure. In auto body painting applications, infrared technology ensures that coatings adhere properly, leading to more durable finishes and reducing the overall time required for bodywork restoration projects.

The Impact on Shop Productivity: Advantages and Time Savings

The adoption of infrared curing equipment in a vehicle body shop brings about significant advantages that directly impact overall productivity. One of the key benefits is the rapid drying and curing process it offers, which can save considerable time compared to traditional methods. This efficiency is particularly noticeable in auto detailing and vehicle body repair processes where speed is essential to meet customer demands and manage workloads.

With infrared technology, the energy emitted speeds up chemical reactions, ensuring that paints, adhesives, and coatings set much faster. This leads to reduced cycle times for various tasks, enabling shops to handle a higher volume of vehicles in a given timeframe. As a result, shop managers can optimize their operations, improve job turnaround, and enhance customer satisfaction by delivering services more efficiently.

Optimizing Processes and Future Considerations for Enhanced Efficiency

Infrared curing equipment has revolutionized many industries, including auto frame repair, car paint repair, and car dent repair, by significantly optimizing processes. This technology offers precise control over the curing process, reducing both cycle times and material waste. By quickly hardening coatings, adhesives, and sealants, infrared systems enhance productivity and streamline workflow in workshops, allowing for faster turnaround times and increased customer satisfaction.

Looking ahead, the future of infrared curing equipment holds even greater efficiency potential. Advancements in technology are continually improving the versatility and accuracy of these systems, enabling them to adapt to a wider range of applications across various sectors. As industries strive for even higher levels of productivity, the integration of smart sensors and automated processes will further refine the role of infrared curing equipment, ensuring that it remains at the forefront of enhancing overall shop productivity.

Infrared curing equipment has emerged as a game-changer in industrial shops, significantly enhancing productivity through rapid drying and curing processes. By understanding its unique functionality and optimizing its integration into existing workflows, businesses can experience substantial time savings and improved efficiency. As the demand for faster production cycles continues to rise, investing in infrared technology becomes an increasingly strategic move, promising a brighter future for shop operations.