Computer-aided repair design (CARD) software revolutionizes vehicle repairs by providing precise tools for detailed repair planning. Using 3D modeling and virtual simulations, CARD enhances accuracy, reduces time, and minimizes costs compared to manual methods. Adhering to best practices, including high-quality data and industry-standard software, ensures effective CARD implementation for superior repair outcomes.

In today’s tech-driven world, computer-aided repair design (CARD) techniques are revolutionizing the way we approach complex repairs. This comprehensive guide delves into the intricacies of CARD software, exploring its key features and tools that streamline efficiency. Learn best practices for accurate and effective design implementation, empowering you to navigate intricate repair processes with confidence. By mastering these techniques, professionals can enhance productivity and ensure superior outcomes in diverse industries.

- Understanding Computer-Aided Repair Design Software

- Key Features and Tools for Efficient Repairs

- Best Practices for Accurate and Effective Designs

Understanding Computer-Aided Repair Design Software

Computer-aided repair design software has revolutionized the way collision centers, auto glass repair shops, and vehicle repair facilities approach their work. This advanced technology provides a suite of tools that streamline the design process, ensuring accuracy and efficiency from start to finish. By integrating digital solutions, professionals in these industries can create detailed, precise plans for repairs, enabling them to effectively communicate with clients and stakeholders.

These software platforms offer a range of features, including 3D modeling, virtual prototyping, and simulation capabilities. With such tools, technicians can virtually visualize the repair process, predict potential issues, and optimize solutions. This not only enhances the overall quality of work but also reduces the time and cost associated with traditional manual design methods. As technology continues to evolve, computer-aided repair design software will undoubtedly play a pivotal role in shaping the future of vehicle repair services.

Key Features and Tools for Efficient Repairs

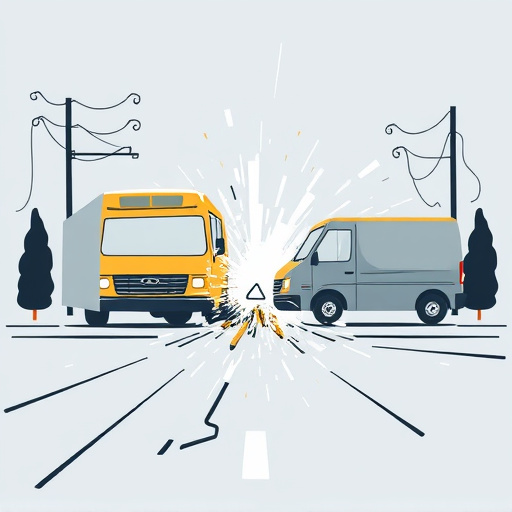

In today’s digital age, computer-aided repair design (CARD) has revolutionized the way we approach vehicle repairs, particularly in body shop services. Efficient CARD tools offer precise measurements and detailed visualizations, enabling technicians to navigate complex auto maintenance tasks with enhanced accuracy. These systems streamline the process from initial assessment to final restoration, ensuring that even minor repairs like a fender bender are handled swiftly and effectively.

Key features of modern CARD software include advanced 3D modeling capabilities, allowing for virtual simulations of repair procedures. This technology not only aids in identifying damage but also facilitates the estimation of parts required, minimizing errors often associated with manual calculations. Additionally, these platforms provide access to a vast library of vehicle models and configurations, simplifying the task of locating specific repair manuals and specifications. Integrating CAD (Computer-Aided Design) principles ensures repairs are not just visually accurate but geometrically precise as well, leading to longer-lasting and more aesthetically pleasing outcomes for body shop services.

Best Practices for Accurate and Effective Designs

Achieving precision and efficiency in Computer-Aided Repair Design (CARD) requires adhering to best practices that ensure accurate and effective outcomes. Before initiating any design, thorough understanding of the vehicle’s structure, including detailed 3D models, is crucial. This involves meticulous research and high-quality input data to avoid errors later in the process. Utilizing industry-standard software, keeping tools and techniques up-to-date, and double-checking dimensions, tolerances, and material properties are all vital steps for success.

For car body restoration or automotive repair projects, CARD offers immense benefits, allowing for precise measurements and modifications of car bodywork. This is particularly valuable when dealing with intricate shapes, curves, and joints in vehicle components. By integrating advanced simulation tools, designers can predict how a car body will perform under various conditions, ensuring structural integrity and optimal repair solutions. Regular backups and version control are also essential best practices to mitigate risks and facilitate collaboration among design teams.

Computer-aided repair design (CARD) software is transforming the way we approach complex repairs, offering precise solutions in less time. By understanding the key features, best practices, and leveraging efficient tools, professionals can maximize the benefits of CARD techniques. This guide equips readers with the knowledge to navigate this powerful technology, ensuring accurate, effective, and streamlined repair processes. Integrate these practices into your workflow for enhanced productivity and improved outcomes in the digital age.