Electronic measuring equipment, featuring sensors, circuits, and algorithms, is a modern workshop game-changer. Digital multimeters, laser tools, and CAD software enable precise diagnoses and repairs across industries like automotive and bodywork. These devices enhance accuracy in tasks from electrical testing to detailed design work, ensuring efficiency and safety through reliable measurements. Key types include calipers, distance meters, multimeters, and 3D scanners, each with unique applications. Safety and regular calibration are vital for maintaining the integrity of these high-precision tools.

“Unraveling the world of electronic measuring equipment: a crucial guide for professionals and enthusiasts alike. From understanding the fundamental concepts to exploring diverse tools like multimeters, oscilloscopes, and calipers, this article offers an insightful journey. Discover their applications across various industries, from construction to electronics manufacturing. Furthermore, we delve into safety practices and maintenance tips to ensure accurate readings and prolong device lifespan. Equip yourself with knowledge on these indispensable electronic measuring tools.”

- Understanding Electronic Measuring Equipment: The Basics

- Types of Electronic Measuring Tools and Their Applications

- Importance, Safety Precautions, and Maintenance Tips

Understanding Electronic Measuring Equipment: The Basics

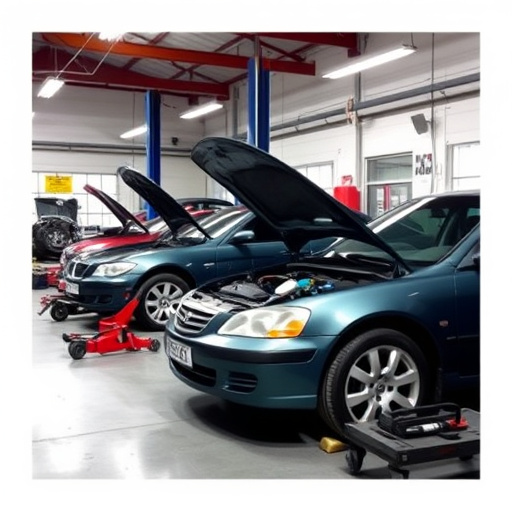

Electronic measuring equipment plays a pivotal role in modern workshops, revolutionizing how we assess and rectify issues across various industries, from automotive repair to vehicle bodywork. These tools leverage advanced technologies like sensors, circuits, and software algorithms to deliver precise measurements, enabling technicians to diagnose problems efficiently.

At its core, such equipment includes devices like digital multimeters, laser measuring tools, and computer-aided design (CAD) software. Digital multimeters, for instance, allow users to measure voltage, current, resistance, and more, while laser measures offer unparalleled accuracy in gauging distances and angles. CAD programs, meanwhile, facilitate the creation of detailed plans and specifications, enhancing precision during auto frame repair or other intricate vehicle bodywork tasks.

Types of Electronic Measuring Tools and Their Applications

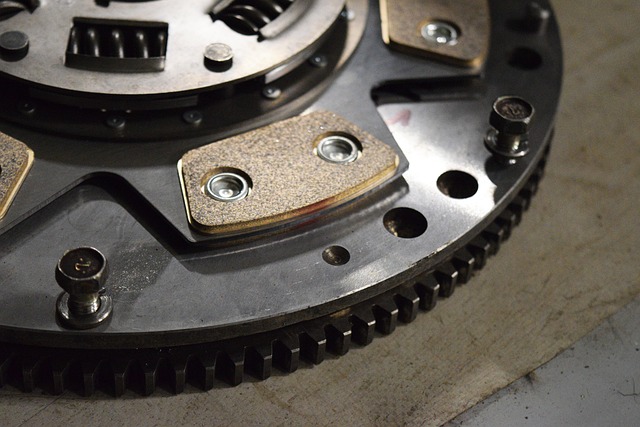

The world of electronic measuring equipment offers a diverse range of tools designed to cater to various industries and applications. From precision engineering to automotive repairs, these devices play a pivotal role in ensuring accuracy and efficiency. Among the most common types are digital calipers, which excel at measuring dimensions with remarkable accuracy, making them indispensable for tasks such as bumper repair and auto body work in vehicle body shops.

Other notable tools include laser distance meters, ideal for quickly and accurately measuring distances, heights, and areas; multimeters for testing electrical circuits and components; and 3D scanners, which capture detailed measurements of objects’ surfaces, useful across industries from manufacturing to architecture. Each tool has its unique application, whether it’s ensuring intricate metalwork alignment in a vehicle body shop, facilitating complex auto body repairs, or aiding in the creation of precise architectural models.

Importance, Safety Precautions, and Maintenance Tips

The reliability and accuracy of electronic measuring equipment play a pivotal role in various industries, especially in fields like automotive, construction, and manufacturing. This advanced technology ensures precise measurements, enabling professionals to make informed decisions and achieve exceptional results. Accurate readings from devices such as calipers, micrometers, and digital gauges are crucial for quality control, ensuring that products meet the required standards. In the realm of auto maintenance and collision repair shops, these tools are indispensable, helping mechanics diagnose issues and perform precise repairs.

When it comes to handling electronic measuring equipment, safety is paramount. Proper precautions must be taken to protect against electrical hazards, static discharge, and potential injuries associated with high-precision instruments. Regular maintenance is equally vital; keeping these devices clean, calibrated, and in optimal condition ensures their longevity and accuracy. Simple steps like periodic calibration, using appropriate protective gear during operation, and storing equipment in controlled environments can significantly extend their lifespan and maintain their reliability, fostering a safe and efficient work environment, especially in the auto collision repair sector.

Electronic measuring equipment plays a vital role in various industries, offering precise and efficient data collection. By understanding the different types and their applications, as well as implementing safety precautions and regular maintenance, users can maximize the benefits of these tools. Whether for construction, manufacturing, or research, investing in reliable electronic measuring devices is key to achieving accurate results and ensuring safety on the job.