Delay concerns in collision repair cause significant scheduling disruptions due to part availability issues, labor shortages, and weather conditions. To mitigate these delays, collision centers should implement proactive measures like robust supply chains, tech-driven scheduling, structured workflow systems, advanced equipment, and regular maintenance checks, ensuring efficient resource management, higher quality work, and faster turnarounds to meet customer expectations.

Delay concerns in collision repair can significantly impact workshop scheduling and resource management, leading to inefficient workflows and higher costs. This article delves into the root causes of these delays, exploring how they affect the entire repair process. We provide actionable strategies to minimize delays, optimize repair times, and enhance overall efficiency in collision workshops. By understanding and addressing delay concerns, professionals can ensure smoother operations and better customer satisfaction.

- Understanding Delay Concerns in Collision Repair

- Impact on Workshop Scheduling and Resource Management

- Strategies to Minimize Delays and Optimize Repair Processes

Understanding Delay Concerns in Collision Repair

Delay concerns in collision repair refer to the various factors that can hinder the timely completion of auto body services and impact the overall repair scheduling process. These delays can arise from multiple sources, each causing disruptions in the workflow of collision repair shops. Understanding these delay concerns is crucial for managing expectations and ensuring efficient operations. Common issues include availability of parts, especially for specialized or rare vehicle models, which can slow down the replacement process.

Another significant factor is labor shortages, where skilled auto body technicians might be scarce, leading to backlogs and extended turnaround times. Weather conditions also play a role, with adverse weather events often causing delays in both part deliveries and work schedules. Efficient collision repair services rely on proactive measures to mitigate these delay concerns, such as maintaining robust supply chains, employing tech-driven scheduling systems, and ensuring a steady stream of skilled labor.

Impact on Workshop Scheduling and Resource Management

The delay concerns collision often result in significant disruptions to workshop scheduling and resource management. When a vehicle arrives for repair, every minute counts. Delays in assessing damage, acquiring parts, or performing complex car body repair tasks can pile up, affecting not just the current job but also subsequent appointments. This ripple effect can lead to backlogs, causing frustration among both customers and technicians who have limited availability.

Effective collision center management requires a delicate balance. While ensuring top-quality vehicle paint repair and meticulous attention to detail, staff must also be adept at multitasking and flexible scheduling. Leveraging technology for efficient resource allocation, such as digital appointment booking and parts inventory systems, can mitigate delays. Ultimately, streamlining these processes not only benefits the collision center but also enhances customer satisfaction by minimizing wait times.

Strategies to Minimize Delays and Optimize Repair Processes

Minimizing delays in collision repair is key to optimizing repair scheduling and ensuring efficient service. Auto body shops can implement several strategies to streamline their processes. One effective method is adopting a structured workflow system, enabling seamless communication between departments and technicians. This includes establishing clear protocols for damage assessment, parts ordering, and repair techniques, minimizing miscommunication and mistakes that often cause delays.

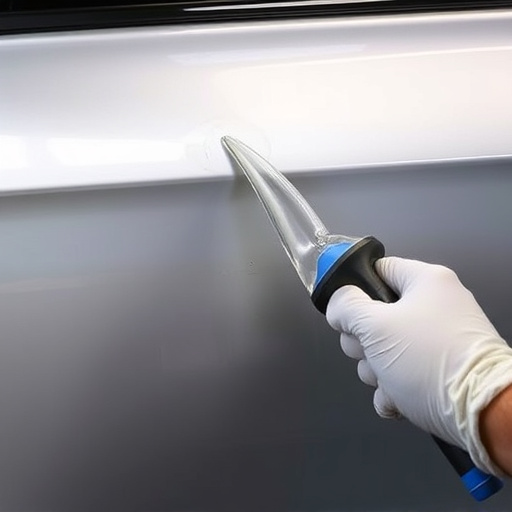

Additionally, investing in advanced equipment and training staff on their efficient use can significantly reduce turnaround time. Up-to-date technology, such as precision measurement tools and automated painting systems, enhances accuracy and speed. Utilizing these modern car bodywork services not only improves repair quality but also allows for faster turnaround, meeting customer expectations. Regular maintenance checks and proactive monitoring of inventory levels are other practical approaches to avoid delays related to parts availability and supply chain issues, ensuring prompt auto body repairs.

Delay concerns in collision repair significantly impact workshop scheduling and resource management, leading to inefficient operations. By understanding these delays and implementing strategic solutions, repair shops can optimize their processes, enhance productivity, and better serve customers. Embracing efficient practices ensures a smoother workflow, reduces wait times, and ultimately fosters a positive customer experience.