Preparation is key for effective quality control inspections, with checklists guiding inspectors through verification of tools, equipment, documentation, and safe work areas, especially auto body repair-specific needs. Past inspection reports are reviewed for recurring problems, allowing for targeted prioritization. The final walkthrough ensures meticulous craftsmanship in repairs, from paint finishes to interior trim alignment. Documenting findings accurately through high-quality images and notes serves as a permanent record, facilitating communication and analysis of patterns or recurring issues, enabling informed decisions and continuous refinement of quality control strategies.

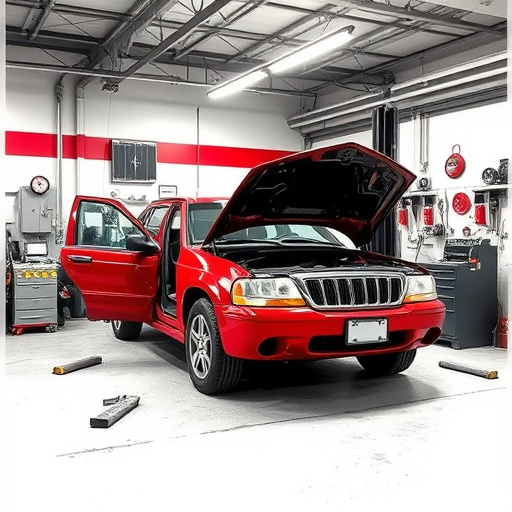

Ensure flawless projects with a comprehensive final walkthrough checklist tailored for quality control inspections. Our guide breaks down essential pre-inspection preparation, step-by-step walkthrough procedures, and post-review documentation for consistent, efficient results. Discover how this systematic approach enhances project quality, reduces errors, and streamlines your quality control processes in any industry. Implement our checklist today for improved efficiency and superior outcomes in every inspection.

- Pre-Inspection Preparation Checklist

- Conducting the Final Walkthrough

- Post-Walkthrough Documentation and Review

Pre-Inspection Preparation Checklist

Before initiating a quality control inspection, thorough preparation is key to ensuring an efficient and effective process. A comprehensive pre-inspection checklist serves as a guide for inspectors, helping them stay organized and focused on identifying potential issues across various stages of a project. This checklist typically includes verifying that all necessary tools and equipment are readily available, ensuring the work area is clean and safe, and checking if all relevant documentation and specifications are easily accessible. For auto body repairs or car body restoration projects, this might involve inspecting the workspace for proper ventilation to mitigate the risk of fumes and ensuring specialized tools for vehicle body repair are in place.

Additionally, the checklist should encompass a review of past inspection reports to identify recurring problems or areas that require special attention. By doing so, inspectors can prioritize their efforts and allocate more time to potential problem zones. This proactive approach not only streamlines the quality control inspection process but also contributes to delivering higher-quality outcomes in auto body repairs and car body restoration projects.

Conducting the Final Walkthrough

The final walkthrough is a pivotal step in any quality control inspection process, especially in the domain of automotive body shops and classic car restoration projects. It’s the moment when the dust settles and the true craftsmanship of the work becomes evident. Inspectors meticulously traverse each section of the vehicle, scrutinizing every detail from exterior paint finishes to interior trim alignment. This rigorous examination ensures that every repair, whether it’s a car collision repair or meticulous classic car restoration, meets the highest standards.

During this walkthrough, the focus shifts from identifying major issues to verifying the precision and adherence to specifications. It involves checking crucial elements like panel gaps, alignment of parts, and paint consistency. In an automotive body shop environment, where cars are transformed from damaged states to like-new conditions, a thorough final walkthrough guarantees customer satisfaction and maintains the shop’s reputation for excellence in car collision repair and classic car restoration services.

Post-Walkthrough Documentation and Review

After completing the final walkthrough, meticulous documentation becomes paramount. Inspectors meticulously record all findings, ensuring every detail is captured accurately. This includes taking high-quality images of both compliant and non-compliant areas, along with comprehensive notes describing any issues discovered during the quality control inspection. The documentation process acts as a permanent record, facilitating clear communication among the inspection team, management, and stakeholders.

Post-walkthrough reviews are crucial for enhancing the overall effectiveness of the quality control process. These reviews involve analyzing the documented findings to identify patterns, trends, or recurring problems. By examining the data collected during each walkthrough, teams can pinpoint areas requiring improvement in car dent repair, auto painting, or other relevant services. This analytical approach enables them to make informed decisions, implement necessary changes, and continually refine their quality control strategies for optimal results.

A comprehensive final walkthrough checklist is an indispensable tool for any quality control inspection process. By meticulously following this structured guide, teams can ensure that no detail is overlooked, leading to more efficient and effective quality assurance. This systematic approach, covering pre-inspection preparation, the actual walkthrough, and subsequent documentation, allows for a thorough evaluation of products or services, ultimately enhancing overall quality standards in any industry. Incorporating these practices into your quality control workflow is key to maintaining consistency and delivering top-tier results in every final inspection.