Model Y body damage repair involves a meticulous assessment process to identify and categorise damage, guiding technicians through specialised tools for accurate evaluation. This initial step optimises shop operations by streamlining repairs, ensuring efficient prioritisation and technique selection. Advanced technologies like CAD software and digital communication enhance performance, leading to faster turnarounds, reduced costs, higher quality, better safety standards, and increased customer satisfaction.

In today’s automotive landscape, efficient repairs are key to keeping customers satisfied and businesses thriving. For Tesla’s popular Model Y, proper body damage assessment and streamlined repair processes are essential for both quality and efficiency. This article delves into the intricacies of Model Y body damage repair, offering a comprehensive guide for assessing and fixing common issues. From understanding assessment methods to implementing operational improvements, these strategies ensure top-notch repairs and enhanced shop productivity.

- Understanding Model Y Body Damage Assessment

- Efficient Repair Processes: A Step-by-Step Guide

- Streamlining Shop Operations for Better Results

Understanding Model Y Body Damage Assessment

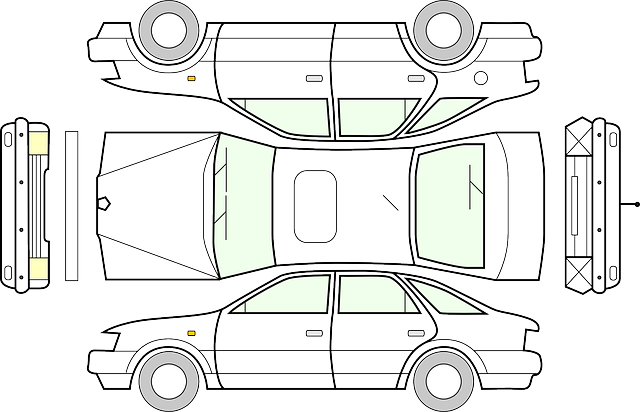

Assessing Model Y Body Damage is a meticulous process that forms the bedrock for effective repair strategies. It involves a comprehensive examination to identify and categorise various types of damage, ranging from minor dents and scratches to more significant structural issues. This initial evaluation is crucial as it dictates the course of action, ensuring every detail is considered before proceeding with any Model Y body damage repair.

Specialised tools and expertise are employed to detect even the subtlest imperfections on the vehicle’s exterior. This includes close inspection of panel gaps, paint analysis, and 3D scanning technology to pinpoint misalignments or deformities. Accurate assessment facilitates efficient shop operations by streamlining the repair process, enabling technicians to prioritise tasks and utilise the right techniques for each unique damage case, whether it’s simple dent removal, auto glass replacement, or more intricate car restoration work.

Efficient Repair Processes: A Step-by-Step Guide

Efficient Repair Processes for Model Y Body Damage Repair

The first step in Model Y body damage repair is a thorough inspection to assess the extent of the damage. This involves visually examining the vehicle’s exterior and interior, as well as performing diagnostic scans to identify any electronic or mechanical issues. Once the damage is mapped out, the repair team can prioritize tasks and allocate resources accordingly.

The next phase focuses on preparing the car for actual repairs. This includes removing damaged panels, replacing parts, and ensuring all necessary tools and materials are in place. Skilled technicians then commence the repair process, following a systematic approach to each task. Regular quality checks at every stage help maintain high standards. Finally, upon completion, a final inspection is conducted to ensure the car meets safety regulations and aesthetic expectations before handing it back to the client. This step-by-step guide ensures streamlined operations and superior results in Model Y body damage repair, reflecting the efficiency of professional car restoration services.

Streamlining Shop Operations for Better Results

In the realm of Model Y body damage repair, streamlining shop operations is a game-changer. By optimizing processes and adopting efficient practices, automotive body shops can significantly enhance their overall performance. This involves implementing advanced technologies, such as computer-aided design (CAD) software, which enables precise measurements and accurate repairs, thereby reducing time and labor costs. Moreover, integrating digital communication tools allows for seamless coordination among technicians, ensuring a smooth workflow and minimizing delays.

Efficient operations translate to better results in car dent repair and automotive body shop services. With streamlined processes, shops can accommodate more vehicles, reduce wait times, and maintain high-quality standards. Additionally, a well-organized work environment promotes safety and fosters a positive atmosphere for technicians, leading to increased productivity and customer satisfaction. These strategic steps are crucial in staying competitive in the automotive repair services industry.

Model Y body damage repair is a specialized process that, when executed efficiently, can significantly enhance shop operational productivity. By understanding detailed assessment methods and implementing streamlined repair processes, as outlined in this article, automotive professionals can achieve remarkable results while minimizing downtime for these electric vehicles. Embracing efficient operations not only benefits the shop’s bottom line but also contributes to the overall sustainability of the automotive industry by facilitating faster turnarounds and reduced resource consumption.