Mercedes boron steel cutting is a revolutionary technology for car body restoration, utilizing advanced laser techniques on strong, precise boron steel to achieve clean cuts, minimal waste, and intricate repairs. Post-repair structural testing verifies the effectiveness and durability of this method, ensuring repaired vehicles have reliable, safe structures with maintained original strength.

Mercedes Boron Steel Cutting has emerged as a revolutionary technology, enhancing automotive manufacturing with its exceptional strength and durability. This article delves into the intricacies of this innovative process, exploring how it is verified through rigorous post-repair structural testing. We’ll uncover the methodology behind evaluating Mercedes Boron Steel Cutting’s performance and reliability, offering insights into its impact on vehicle construction and safety standards.

- Understanding Mercedes Boron Steel Cutting Technology

- Post-Repair Structural Testing Methodology

- Verifying Cutting Performance and Reliability

Understanding Mercedes Boron Steel Cutting Technology

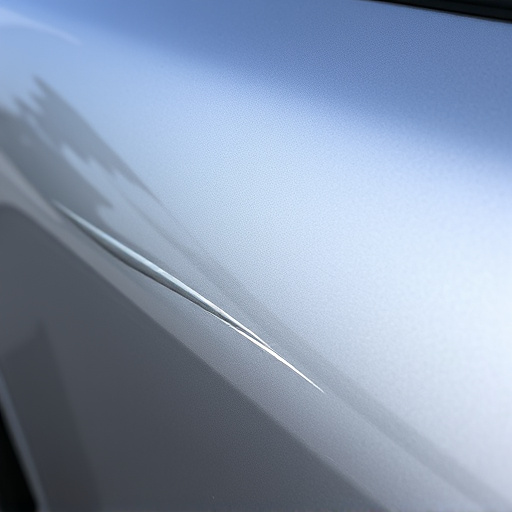

Mercedes Boron Steel Cutting is a revolutionary technology that has transformed the automotive industry, particularly in the realm of car body restoration and scratch repair. This innovative process involves using specialized equipment to precisely cut and shape boron steel, a robust and durable material known for its exceptional strength-to-weight ratio. By employing advanced laser cutting techniques, Mercedes engineers can achieve precise and clean cuts, ensuring minimal material waste and maximizing efficiency during dent removal processes.

The technology’s versatility is evident in various applications, from intricate car body panels to complex automotive components. Its precision allows for the restoration of damaged vehicles to their original specifications, providing a seamless and durable solution. This cutting-edge approach not only enhances the visual appeal of vehicles but also guarantees structural integrity, making it a preferred choice for professionals in the automotive aftercare sector, including those specializing in scratch repair and dent removal.

Post-Repair Structural Testing Methodology

Post-Repair Structural Testing Methodology plays a pivotal role in validating the effectiveness of Mercedes boron steel cutting techniques employed in auto body services. This rigorous process involves meticulous evaluation of the repaired area to ensure structural integrity and precision. Experts utilize advanced measurement tools to assess the alignment, dimensions, and overall strength of the panel after the cutting and repair procedure.

The methodology includes non-destructive testing methods such as ultrasonic scanning and digital 3D measuring systems. These techniques allow for detailed analysis of the internal structure, identifying any potential weaknesses or disparities caused by previous damage or improper repairs. By comparing these findings with original specifications, auto repair services can confirm the quality and accuracy of Mercedes boron steel cutting, ensuring that cars return to the road with reliable and safe structures.

Verifying Cutting Performance and Reliability

In the realm of automotive craftsmanship, ensuring the precision and reliability of cutting processes is paramount, especially when dealing with materials like Mercedes boron steel. To verify the cutting performance of this specialized steel, rigorous post-repair structural testing becomes indispensable. This testing protocol involves meticulous examination to ensure that the cutting edge maintains its integrity, accuracy, and durability—all critical factors for any mercedes benz repair or car paint repair endeavor.

The reliability of Mercedes boron steel cutting is not just about achieving clean, precise lines but also ensuring structural soundness post-repair. Through these tests, manufacturers can verify the steel’s ability to withstand stress and pressure without compromising its original strength, thus guaranteeing a robust and long-lasting outcome for even the most intricate scratch repair or car paint repair tasks.

Through rigorous post-repair structural testing, the superior performance and reliability of Mercedes Boron steel cutting technology have been conclusively verified. This innovative process ensures enhanced structural integrity and longevity for vehicle repairs, setting a new standard in the automotive industry. By leveraging advanced materials like boron steel, Mercedes is revolutionizing the way we approach vehicle repair and maintenance.