Understanding frame damage is crucial for estimating frame repair cost, which varies based on severity and location. Welding, a critical repair technique, offers benefits like structural restoration but increases labor costs and time due to skilled labor requirements. Proper damage assessment helps avoid unnecessary expenses, with minor issues potentially fixed without extensive welding. Comparing quotes from auto body shops balances quality and affordability, as less specialized mechanics can handle minor welding jobs at lower costs.

Welding is often integral to frame repair, but it can significantly impact the overall cost. This article delves into the intricate relationship between welding and frame damage, exploring how welding contributes to repair expenses. We’ll examine various types of frame damage, dissect the pros and cons of welding in repair processes, and offer strategic budgeting insights to help mitigate costs associated with frame repair, ensuring informed decisions for both professionals and consumers.

- Understanding Frame Damage and its Impact on Cost

- The Role of Welding in Frame Repair: Pros and Cons

- Mitigating Expenses: Strategies for Effective Frame Repair Budgeting

Understanding Frame Damage and its Impact on Cost

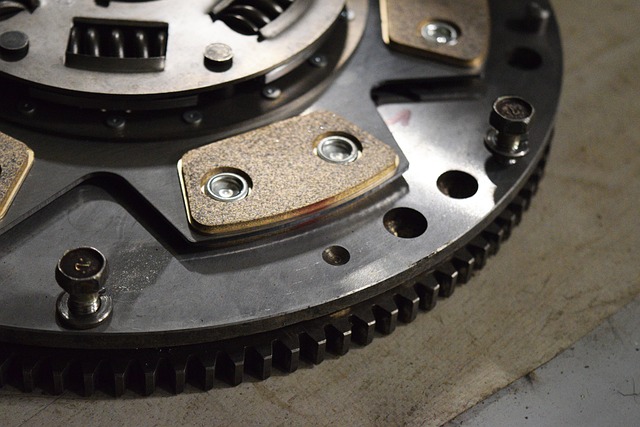

Understanding the extent of frame damage is crucial when estimating a vehicle’s frame repair cost. In automotive collision repair, the frame acts as the car’s backbone, providing structural integrity and safety features. Damage to this critical component can vary greatly, from minor dents and bends to severe crumpling or even complete deformation. Each type of damage requires a specific approach during repairs, impacting both the scope of work and the overall frame repair cost.

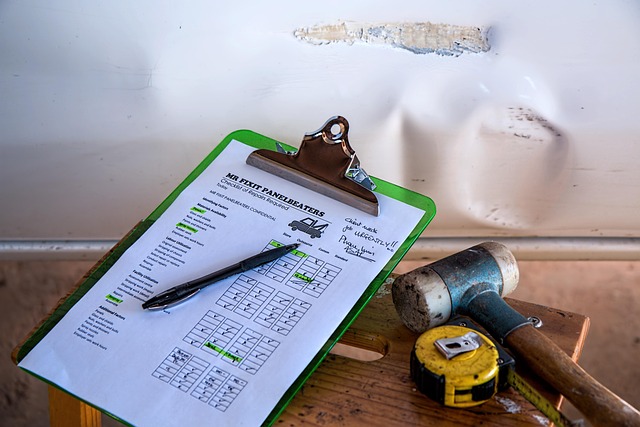

In a car body shop, technicians assess each case individually, considering factors like the severity, location, and extent of the damage. Minor frame issues might only require straightening or minor adjustments, while more significant accidents could demand comprehensive straightening or even replacement parts. These variations directly influence labor costs and the time needed to complete the vehicle repair, ultimately affecting the final frame repair cost.

The Role of Welding in Frame Repair: Pros and Cons

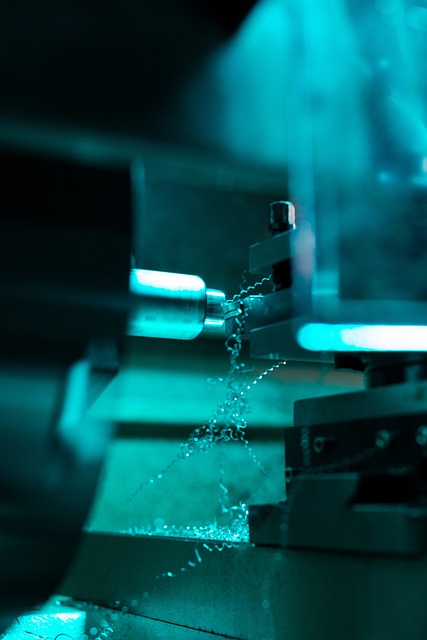

Welding plays a significant role in frame repair, offering both advantages and disadvantages when it comes to estimating the frame repair cost. It is a crucial process for restoring structural integrity to damaged vehicles, especially in cases where the frame has been bent or severely deformed. By melting and fusing metal together, welding allows technicians to join components back into their original alignment, effectively repairing the car’s skeletal framework. This technique is particularly valuable for older vehicles with solid axles and traditional suspension systems, as it can preserve the vehicle’s historical integrity while ensuring safety standards are met.

However, welding also introduces certain complexities that impact frame repair cost. Skilled labor is essential to ensure precise and clean welds, which can increase the overall expense. Additionally, extensive welding may require more time and resources, potentially adding to the labor costs of car bodywork services or car repair services. While it offers robust solutions for frame issues, the process itself can be a challenge, especially in tight quarters, demanding careful consideration during car body restoration processes.

Mitigating Expenses: Strategies for Effective Frame Repair Budgeting

When budgeting for frame repair, it’s essential to understand that welding needs can significantly impact the overall cost. To mitigate expenses, several strategies can be employed. One effective approach is to prioritize and assess the extent of the damage. Not all repairs require complex welding, so identifying minor issues early on can prevent unnecessary costs. For instance, a small dent in a fender or bumper might only need simple straightening techniques rather than extensive welding, keeping the frame repair cost under control.

Additionally, comparing quotes from different auto body shops is crucial. Each shop may have varying rates and expertise in specific vehicle models. Getting several estimates allows you to find a balance between quality work and affordable pricing. Remember, while it’s important to opt for skilled technicians for critical repairs like structural integrity checks and major component replacements (like auto glass repair or bumper repair), minor welding jobs on less critical areas could be done by less specialized mechanics at lower costs, ensuring an efficient frame repair process without breaking the bank.

Welding plays a pivotal role in frame repair, offering both advantages and drawbacks. While it can restore structural integrity, the process may significantly add to the overall frame repair cost. Understanding the extent of frame damage and implementing strategic budgeting techniques are essential to navigate these expenses effectively. By considering alternative methods and prioritizing efficient repairs, vehicle owners can mitigate the financial impact, ensuring a more affordable and comprehensive frame repair experience.