Quality control inspection is a vital process for auto repair and restoration industries, ensuring excellence and consistency. Trained inspectors conduct thorough evaluations, using advanced tools to verify repairs against industry standards and manufacturer specs. Regular training enhances consistent results. Robust quality control procedures mitigate risks, reduce liability, protect shop reputation, and foster customer satisfaction, setting reputable workshops apart in the market.

Quality control (QC) inspection is a vital process that repair shops employ to ensure accuracy and reduce liability. By implementing rigorous QC procedures, shops can mitigate risks associated with faulty repairs, protecting both their reputation and customers. This article delves into the fundamentals of quality control inspection, highlights critical roles within the shop, and emphasizes the significance of consistent QC practices in minimizing legal exposure for automotive repair businesses.

- Understanding Quality Control Inspection Basics

- Key Roles in Ensuring Repair Shop Accuracy

- Mitigating Risk Through Consistent QC Procedures

Understanding Quality Control Inspection Basics

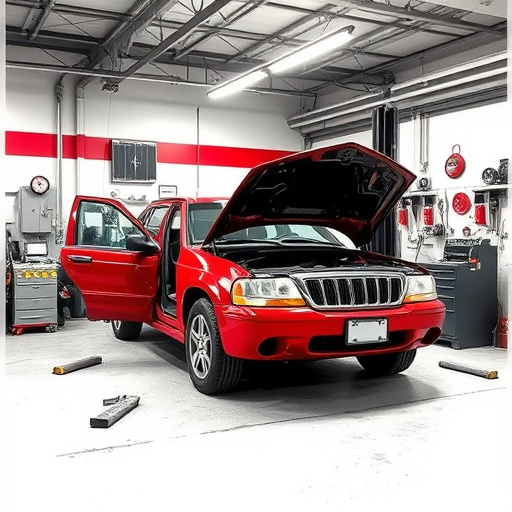

Quality control inspection is a fundamental process that plays a pivotal role in ensuring excellence within auto repair services and vehicle restoration industries. It involves a systematic evaluation of a product or service, in this case, car repairs and renovations, to verify if they meet predefined standards and specifications. This meticulous practice is not just about identifying defects but also about maintaining consistency and upholding the reputation of repair shops.

By implementing robust quality control measures, repair shops can significantly reduce potential liabilities associated with subpar work. These inspections act as a safeguard, ensuring that every vehicle leaving the workshop adheres to safety regulations and performance expectations. This proactive approach not only enhances customer satisfaction but also fosters trust in car repair services, distinguishing reputable workshops from their counterparts.

Key Roles in Ensuring Repair Shop Accuracy

In any collision repair shop, be it a specialized luxury vehicle repair center or a general car collision repair facility, several key roles contribute to ensuring accuracy in repairs. The first line of defense is the highly trained and experienced inspectors who conduct thorough quality control inspections. These professionals are tasked with meticulously evaluating every aspect of the repair process, from the initial assessment of damage to the final quality check. They ensure that all work adheres to industry standards and manufacturer specifications, using advanced tools and techniques for precise measurements and analysis.

The inspector’s detailed reports serve as a critical reference point for technicians. This collaborative effort between inspection and repair teams is vital in minimizing errors and ensuring customer satisfaction. Regular training sessions on quality control procedures further enhance the team’s ability to deliver consistent, high-quality results, whether they’re handling routine maintenance or complex luxury vehicle repair tasks.

Mitigating Risk Through Consistent QC Procedures

Implementing robust quality control (QC) procedures is a powerful strategy for car repair shops to mitigate risks and reduce liability associated with their services. By establishing consistent QC processes, shops can ensure that every repair or service performed adheres to set standards and specifications. This proactive approach significantly minimizes the chances of errors, oversights, or subpar work that could lead to customer dissatisfaction and potential legal repercussions.

For instance, in scratch repair or fender repair services, a detailed QC inspection ensures that the repairs are not only visually appealing but also structurally sound. It involves meticulous checks at each stage of the process, from assessing the damage to evaluating the quality of materials used and the craftsmanship. Such thoroughness not only guarantees customer satisfaction but also provides a layer of protection for the shop against claims of negligence or poor workmanship.

Quality control (QC) inspection plays a pivotal role in minimizing liability for repair shops. By implementing consistent QC procedures, shops can ensure accurate repairs, mitigate risks, and protect their reputation. Understanding the basics of QC, assigning clear roles, and adhering to structured procedures are essential steps towards achieving this goal. A robust quality control system not only enhances customer satisfaction but also serves as a shield against potential legal issues.