Frame machine repair demands a thorough pre-repair assessment to determine damage extent, structural imbalances, and complementary service needs. This process considers vehicle age, condition, and maintenance history for accurate diagnosis, preventing further damage. Meticulous inspections using specialized tools identify issues, followed by cleaning, precise adjustments, coating, and reinforcement. Regular post-repair maintenance, including cleaning and lubrication, ensures sustained optimal performance and longevity of the frame machine.

“Optimizing Equipment Manufacturing (OEM) offers invaluable insights into the art of frame machine repair, ensuring these versatile tools remain in top condition. This comprehensive guide delves into the essential pre-repair assessments crucial for accurate diagnosis. We then provide a step-by-step repair process, detailing effective techniques. Post-repair maintenance is also covered, emphasizing its role in longevity and performance. By adhering to OEM recommendations, technicians can master frame machine repair, enhancing efficiency and extending equipment lifespan.”

- Understanding Frame Machine Repair: Essential Pre-Repair Assessments

- Step-by-Step Guide to Effective Frame Machine Repair Techniques

- Post-Repair Maintenance: Ensuring Longevity and Performance of Frame Machines

Understanding Frame Machine Repair: Essential Pre-Repair Assessments

Understanding Frame Machine Repair involves a meticulous pre-repair assessment to ensure the process is both effective and efficient. Before diving into any frame machine repair, it’s crucial to conduct a thorough inspection of the vehicle. This includes evaluating the extent of damage, checking for any structural imbalances, and assessing the need for accompanying services like tire services or car paint repair. Auto repair specialists should also consider the age and condition of the vehicle’s frame, as well as its historical maintenance record, to accurately gauge the required repairs.

These initial assessments are vital for setting realistic expectations and avoiding unnecessary procedures. Proper diagnosis is key in preventing further damage and ensuring that auto repair services align with the specific needs of the vehicle. By taking this strategic approach, repair technicians can deliver high-quality results, ensuring that the vehicle’s structural integrity is restored to its optimal condition.

Step-by-Step Guide to Effective Frame Machine Repair Techniques

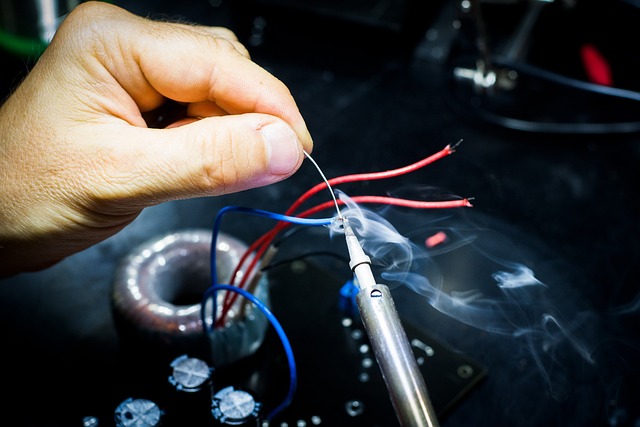

Proper frame machine repair is a critical aspect of auto bodywork, ensuring vehicles return to their pre-accident condition. To achieve this, OEM (Original Equipment Manufacturer) recommends a systematic approach that involves several key steps. First, thoroughly inspect the frame for any damage or misalignments using specialized tools designed for accurate measurements. This initial evaluation helps identify areas needing repair and ensures every detail is accounted for.

Next, prepare the frame by cleaning it to remove dirt, grease, or debris that could interfere with bonding or painting. Following this, make precise cuts or adjustments as required to realign the frame components. Utilize high-quality tools and materials throughout the process, adhering strictly to manufacturer guidelines. Once the frame is properly aligned and prepared, apply appropriate coatings or reinforcements to prevent future damage, effectively completing the frame machine repair process in a collision repair shop or auto bodywork facility.

Post-Repair Maintenance: Ensuring Longevity and Performance of Frame Machines

After successful frame machine repair, proper maintenance is key to maintaining longevity and optimal performance of your equipment. Regular cleaning and inspection are essential steps in this process. Remove all debris and dirt from the machine’s surface and internal components after each use to prevent dust buildup, which can lead to wear and tear over time.

Additionally, keeping the frame machine well-lubricated according to the manufacturer’s recommendations ensures smooth operation and prevents metal-on-metal friction. Consistent maintenance not only prolongs the life of your frame machine but also guarantees it continues to deliver precise results in auto dent repair, auto painting, and other related services.

Proper frame machine repair is a critical aspect of maintaining equipment longevity and performance. By understanding essential pre-repair assessments, following effective step-by-step techniques, and implementing post-repair maintenance, OEMs can ensure their machines operate at peak efficiency. Adhering to these recommendations not only extends the lifespan of frame machines but also minimizes downtime, ultimately contributing to enhanced operational productivity.