Structural damage repair in unibody and frame vehicles requires specialized skills and tools due to their intricate designs. The process begins with a comprehensive inspection using advanced diagnostics to uncover hidden damage, from frame deformities to alignment issues. Repairs involve meticulous disassembly, realignment of the frame, replacement of damaged parts, and careful painting to restore vehicles to pre-incident condition while ensuring safety standards are met, ultimately enhancing road safety and vehicle reliability.

In today’s automotive landscape, understanding structural damage repair is paramount. Whether dealing with unibody or frame vehicles, recognizing subtle signs of harm is crucial for safety and vehicle longevity. This comprehensive guide delves into the intricacies of structural damage assessment, explores essential safety considerations, and provides a step-by-step approach to effective repairs. By mastering these techniques, professionals can ensure vehicles return to their original integrity and performance.

- Understanding Structural Damage in Unibody and Frame Vehicles

- Assessment and Safety Considerations for Repairs

- Step-by-Step Guide to Effective Structural Damage Repair Techniques

Understanding Structural Damage in Unibody and Frame Vehicles

Structural damage in unibody and frame vehicles can arise from a variety of incidents, including accidents, natural disasters, or manufacturing defects. Unibody cars, known for their lightweight construction and rigid structure, often sustain damage that requires precise repair techniques to ensure safety and performance. The unibody, which combines the body and chassis into a single unit, makes traditional auto frame repair more complex. This complexity necessitates specialized knowledge and equipment to accurately assess and rectify misalignments or deformations.

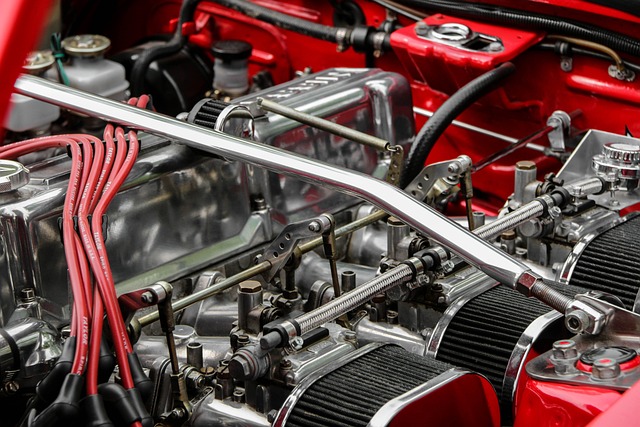

Collision repair services play a crucial role in restoring these vehicles to their pre-incident condition. Automotive repair technicians must employ advanced diagnostic tools to pinpoint the extent of structural damage, which may involve hidden remnants that require careful inspection. Effective structural damage repair involves not just fixing visible dents and cracks but also realigning components, replacing damaged parts, and ensuring the vehicle meets safety standards. This meticulous process ultimately enables vehicles to return to their original state, maintaining their integrity and reliability on the road.

Assessment and Safety Considerations for Repairs

When assessing structural damage repair for unibody or frame vehicles, safety is paramount. Before beginning any repairs, a thorough inspection is crucial to identify all damage, including hidden issues that could impact vehicle integrity. This involves meticulous examination of the car’s frame, unibody components, and critical structural elements using advanced diagnostic tools. Technicians must consider factors like the extent of deformation, alignment issues, and potential weak spots to ensure the safety of both the vehicle and its occupants moving forward.

During this phase, auto repair services professionals also evaluate the condition of auto glass repair, checking for cracks or breaks that could compromise visibility and safety. They may also recommend car paint services to address any cosmetic damage that could affect the vehicle’s structural strength over time. The primary goal is to restore the vehicle to its original specifications while adhering to strict industry standards and regulations to prevent future hazards on the road.

Step-by-Step Guide to Effective Structural Damage Repair Techniques

Structural damage repair is a critical process for both unibody and frame vehicles, especially after a vehicle collision. To effectively undertake this task, here’s a step-by-step guide:

1. Assess the Damage: Begin by thoroughly inspecting the vehicle to identify all structural damage. This includes looking for bent or cracked body panels, misaligned frames, and damaged components like doors, fenders, and hoods. Using specialized tools, measure the extent of deformation and note critical areas that need immediate attention.

2. Safety First: Before proceeding with any repair, ensure the vehicle is safe to work on. This involves securing the vehicle on a reliable jack and stand system, ensuring adequate ventilation, and donning personal protective equipment (PPE) such as gloves, safety glasses, and ear protection.

3. Disassemble Affected Components: Carefully disassemble damaged parts to gain access to hidden damage or areas that require adjustment. This step requires precision and a thorough understanding of the vehicle’s structure. Use specialized tools designed for auto body restoration to avoid causing further damage.

4. Realign and Straighten: Utilize alignment equipment to realign the frame and straighten any bent metal. This ensures proper structural integrity and a smooth, even surface for subsequent repairs.

5. Repair or Replace: Depending on the severity of the damage, decide whether to repair or replace affected components. For minor damages, specialized auto body restoration techniques can be employed, while major issues may necessitate complete replacement parts.

6. Paint and Finish: Once all structural repairs are complete, prepare the surface by sanding and cleaning. Apply high-quality paint and allow it to dry thoroughly. This step ensures not only a visually appealing finish but also protects the vehicle from future corrosion.

Structural damage repair is a critical process that ensures the safety and integrity of unibody and frame vehicles. By understanding the nature of structural damage, implementing thorough assessment protocols, and adhering to effective repair techniques, professionals can restore these vehicles to their pre-incident conditions. This comprehensive guide highlights the essential steps in the repair process, emphasizing the importance of precision, safety, and quality control for optimal results.