Composite material repair is a specialized field crucial for industries like aerospace, automotive, and construction. Skilled technicians use tailored methods to address unique challenges posed by these materials' complex structures. Advanced repairs demand specialized tools, training, and quality assurance, especially in automotive applications where composite components enhance safety and efficiency. Auto body shops investing in equipment and courses ensure precise, high-quality repairs while meeting stringent safety standards.

In today’s advanced manufacturing landscape, composite materials are revolutionizing industries due to their exceptional strength-to-weight ratio. However, repairing these complex structures presents unique challenges. This article explores the pivotal role of expertise in enhancing composite material repair processes. We delve into understanding the properties and challenges of composites, highlighting why skilled technicians are indispensable. Additionally, it discusses advanced repair techniques, tools, training, and quality assurance methods that underscore the importance of expert knowledge in ensuring robust and reliable composite repairs.

- Understanding Composite Materials: Properties and Challenges

- The Importance of Expertise in Repair Techniques

- Advanced Repairs: Tools, Training, and Quality Assurance

Understanding Composite Materials: Properties and Challenges

Composite materials, a modern marvel in various industries, are known for their exceptional strength-to-weight ratio and durability. These materials, often used in aerospace, automotive, and construction sectors, consist of two or more distinct components with unique properties combined to create a new material with superior characteristics. For instance, carbon fiber reinforced polymers offer high stiffness and low weight, making them ideal for building lightweight yet robust structures. However, repairing composite materials presents unique challenges compared to traditional metal repairs.

When damage occurs in composite structures, such as cracks or delaminations, addressing these issues requires a deep understanding of material behavior. Unlike conventional collision repair processes focusing on auto glass replacement or auto repair services, composite material repair involves precise techniques and specialized knowledge. The challenge lies in ensuring the integrity of the entire structure, as repairs must be tailored to each specific composite type, considering factors like fiber orientation and matrix composition. This expertise is crucial for maintaining the structural integrity and performance of composite materials across various applications, including automotive components.

The Importance of Expertise in Repair Techniques

The expertise of skilled technicians is paramount in the realm of composite material repair, where precision and knowledge are key. Composite materials, often used in modern vehicle construction, present unique challenges during repair processes due to their complex nature and varied compositions. Unlike traditional metal bodywork, these materials require specialized techniques and tools for effective repair, ensuring structural integrity and aesthetic quality.

A technician’s expertise involves a deep understanding of different composite types, their properties, and the most suitable repair methods. In the case of vehicle dent repair, for instance, an expert can assess the damage and choose between various techniques like heating, cold extraction, or using specialized tools to gently pull out dents, each with its own set of advantages and limitations. This level of knowledge ensures that auto body repair is not just visually appealing but also structurally sound, preventing further complications in the future, whether it’s for vehicle dent repair or more intricate composite material repairs.

Advanced Repairs: Tools, Training, and Quality Assurance

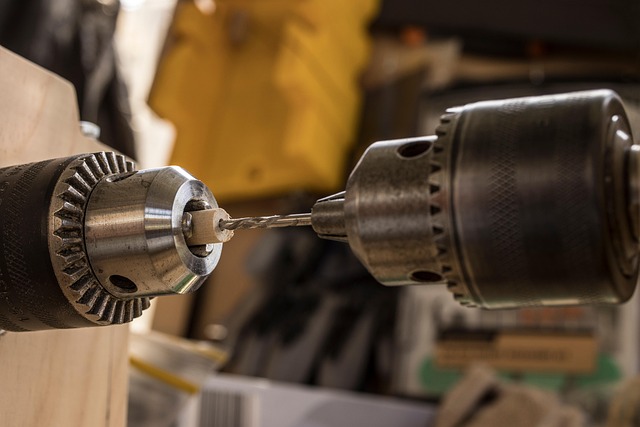

Advanced composite material repairs require a sophisticated approach, encompassing specialized tools, comprehensive training, and stringent quality assurance measures. The automotive industry, particularly car body shops and fleet repair services, is increasingly adopting composite materials due to their lightweight properties and enhanced structural integrity. As such, auto body shops must invest in state-of-the-art equipment designed for intricate composite repairs, ensuring precision and minimal material wastage.

Training plays a pivotal role in equipping technicians with the expertise needed for complex repairs. Specialized courses and workshops focused on composite material repair techniques are essential. These programs provide hands-on experience, enabling professionals to master various methods, from fiber reinforcement to advanced bonding techniques. Furthermore, implementing robust quality assurance protocols guarantees consistent and high-quality repairs across different fleet repair services, maintaining safety standards and customer satisfaction in auto body shops.

In conclusion, the expertise plays a pivotal role in achieving high-quality composite material repairs. By understanding the unique properties and challenges of these materials, professionals can master advanced repair techniques using specialized tools and comprehensive training. Implementing strict quality assurance measures ensures durability and longevity in composite material repair processes, ultimately enhancing structural integrity and safety across various industries.