TIG welding collision systems are in high demand across multiple industries for their versatility and precision in complex joining tasks, particularly in automotive body shops for hail damage repair, manufacturing, construction, and aerospace sectors. These systems use intense heat to bond metals and inert gases to prevent oxidation, offering precise, efficient, and automated collision detection and repair solutions with faster turnaround times and superior quality restoration. Despite initial challenges, their adoption is driven by reduced repair times, scrap rates, and growing demand for efficient collision repairs in the automotive industry.

In today’s industrial landscape, precision and efficiency are paramount. The growing demand for TIG welding collision systems underscores this need for advanced fabrication technologies. This article delves into the intricacies of TIG welding, its diverse applications, and the emergence of automated collision detection systems. We explore the benefits and challenges associated with implementing these innovative solutions, highlighting their crucial role in revolutionizing manufacturing processes.

- Understanding TIG Welding and Its Applications

- The Rise of Automated Collision Detection Systems

- Benefits and Challenges in Implementing TIG Welding Collision Systems

Understanding TIG Welding and Its Applications

TIG welding, or tungsten inert gas welding, is a precision fusion process that joins metals by heating them to create a strong bond. This advanced technique involves directing a concentrated beam of intense heat onto the materials being joined, fusing them together. The use of an inert gas, typically argon or helium, creates an environment free from oxygen, preventing oxidation and ensuring clean welds.

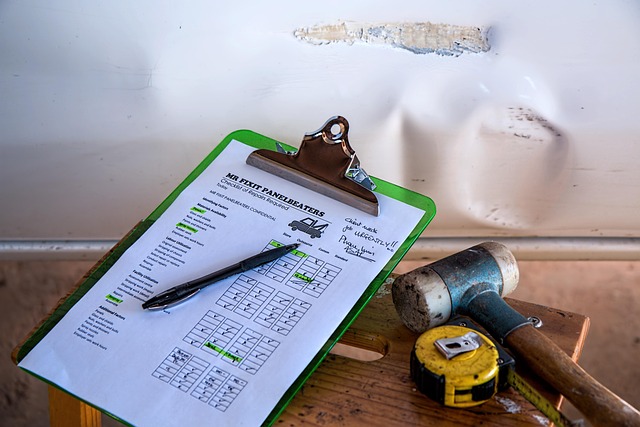

TIG welding collision systems are in high demand across various industries due to their versatility and effectiveness in handling complex joining tasks. These systems are particularly useful for automotive body shops dealing with hail damage repair or fender benders, where precise and consistent welding is crucial for restoring vehicles to their pre-collision condition. The same technology also finds application in manufacturing, construction, and aerospace sectors, ensuring the structural integrity of components and assemblies through collision damage repair processes.

The Rise of Automated Collision Detection Systems

The advent of advanced automation has significantly transformed various industries, and the automotive sector is no exception. One notable development is the rise of automated collision detection systems, which are revolutionizing how car body shops and auto repair services address damage. These cutting-edge technologies employ sophisticated sensors and algorithms to swiftly and accurately identify impacts and deformations on vehicles, providing a crucial step in the repair process.

TIG welding collision systems have emerged as essential tools within these automated frameworks. By seamlessly integrating with advanced scanning and imaging technologies, these systems enable autobody repairs that are both precise and efficient. This not only reduces the time required for collision assessment but also ensures more accurate and consistent results, ultimately enhancing the quality of post-accident vehicle restoration in modern car body shops.

Benefits and Challenges in Implementing TIG Welding Collision Systems

Implementing TIG (Tungsten Inert Gas) welding collision systems offers several significant advantages for industrial processes, particularly in sectors like automotive body work and vehicle bodywork. These advanced systems enhance precision and efficiency, enabling faster repair and restoration times in collision repair centers. With their ability to produce clean, strong welds on a variety of materials, TIG welding collision systems reduce scrap rates and improve overall productivity.

However, there are challenges associated with integrating these systems into existing workflows. Initial costs can be high, requiring substantial investments for specialized equipment and training. Moreover, adapting to TIG welding’s precise requirements may demand modifications in shop layouts and procedures, especially for centers accustomed to traditional methods. Despite these challenges, the growing demand for efficient collision repair services in the automotive industry drives the adoption of TIG welding collision systems, promising long-term benefits for both businesses and consumers.

The growing demand for TIG welding collision systems in industry reflects a trend towards enhanced precision, safety, and efficiency. Automated collision detection systems have revolutionized TIG welding by minimizing errors and maximizing part integrity. While implementation comes with benefits like improved productivity and reduced material waste, challenges such as initial costs and training requirements must be addressed. As the adoption of these systems continues to rise, businesses that invest in cutting-edge TIG welding collision technology will be better positioned to thrive in today’s competitive manufacturing landscape.