Tesla's structural repair training equips professionals with advanced skills in dent repair, structural integrity, and best practices tailored to Tesla manufacturing. This rigorous program ensures high-quality repairs, enhancing vehicle excellence and longevity while meeting Tesla's commitment to cutting-edge technology and superior craftsmanship. Through hands-on learning and meticulous quality control, technicians gain precision for complex repairs across diverse vehicle models, boosting customer satisfaction and fostering body shop service excellence.

Tesla vehicles are renowned for their cutting-edge technology and innovative design. However, like any vehicle, they require meticulous structural repair when damage occurs. This article delves into the critical aspect of Tesla structural repair training, highlighting quality control steps essential for maintaining the brand’s high standards. From understanding stringent repair guidelines to implementing hands-on training, we explore key procedures ensuring consistent, top-tier repairs for these advanced electric vehicles.

- Understanding Tesla Structural Repair Standards

- Key Quality Control Procedures in Repair Process

- Hands-On Training for Consistent Results

Understanding Tesla Structural Repair Standards

Tesla structural repair training is designed to equip professionals with a deep understanding of the brand’s stringent quality control measures. These standards are pivotal in maintaining Tesla’s reputation for innovative, high-quality vehicles. The program delves into meticulous procedures that ensure precision and integrity during car bodywork, particularly focusing on dent repair and structural integrity.

Participants gain insights into best practices tailored to Tesla’s unique manufacturing processes, enabling them to excel in the specialized field of automotive body shop repairs. By mastering these techniques, technicians can contribute to the overall excellence and longevity of Tesla vehicles, aligning with the brand’s commitment to cutting-edge technology and superior craftsmanship.

Key Quality Control Procedures in Repair Process

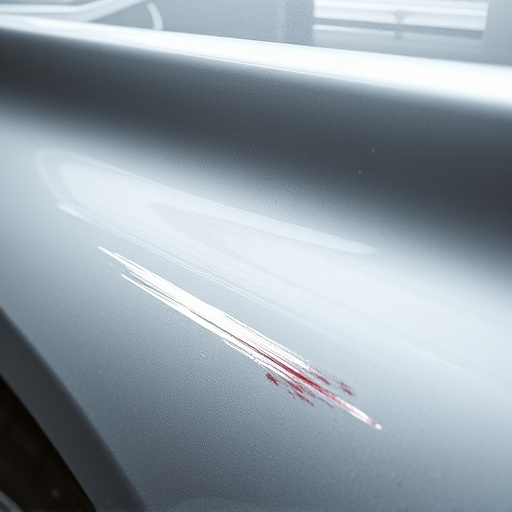

In the realm of Tesla structural repair training, mastering key quality control procedures is paramount to ensuring every fix meets the electric vehicle manufacturer’s stringent standards. The process begins with meticulous inspection, where skilled technicians meticulously examine the damaged area, identifying each imperfection and measuring against original factory specifications. This step is crucial in determining the extent of repairs needed, from panel replacement to intricate welding, ensuring precision and accuracy throughout.

After initial assessment, a comprehensive disassembly and cleaning follow to prepare the vehicle body shop for repair work. This involves removing loose debris, applying degreasers, and meticulously wiping down surfaces to create a clean canvas. In a collision center environment, this meticulous attention to detail sets the stage for seamless integration of new and repaired components, ultimately delivering a superior-quality restoration that matches the excellence of original Mercedes Benz collision repair standards.

Hands-On Training for Consistent Results

The Tesla structural repair training program is designed to provide technicians with hands-on experience and a deep understanding of quality control measures. This immersive approach ensures that every repair, no matter how complex, is executed consistently and to the highest standards. Trainees learn to identify even the subtlest defects, mastering the art of precision alignment and panel replacement. The emphasis on hands-on training translates directly into improved outcomes for automotive body shop customers, ensuring their vehicles not only look like new but also function flawlessly.

This focused training goes beyond mere theory by equipping technicians with practical skills applicable to various vehicle models, including high-end brands like Mercedes Benz Repair. By participating in simulated scenarios and working on real cars, trainees gain valuable experience that prepares them for the diverse challenges they’ll encounter in their daily work. This hands-on approach is crucial in achieving exceptional results, fostering a culture of excellence within the body shop services, and ultimately enhancing customer satisfaction.

Tesla structural repair training is revolutionizing the industry standards with a strong emphasis on quality control. By understanding the key procedures and participating in hands-on training, repair technicians can consistently deliver superior results that meet Tesla’s high standards. This commitment to excellence ensures that repaired vehicles not only function optimally but also maintain their iconic aesthetic appeal, setting a new benchmark in the automotive sector.