Tesla's aluminum welding certification ensures rigorous testing and high-quality control for vehicle components, prioritizing safety and structural integrity. This process is critical for long-term vehicle performance, especially in advanced electric car designs, reducing risks from bodywork damage and preserving original standards during repairs like auto glass replacement.

Tesla’s commitment to innovation extends to its aluminum welding processes, highlighted by their recent certification program. This article delves into the significance of this certification, focusing on how it bolsters long-term vehicle safety and reliability. By understanding Tesla’s stringent aluminum welding standards and the vital role of certification, we uncover the advantages for electric vehicles, ensuring a safer and more durable future in transportation. Explore these key aspects to grasp the full impact of Tesla’s aluminum welding certification.

- Understanding Tesla's Aluminum Welding Standard

- The Role of Certification in Ensuring Safety

- Longevity and Reliability: Benefits for Electric Vehicles

Understanding Tesla's Aluminum Welding Standard

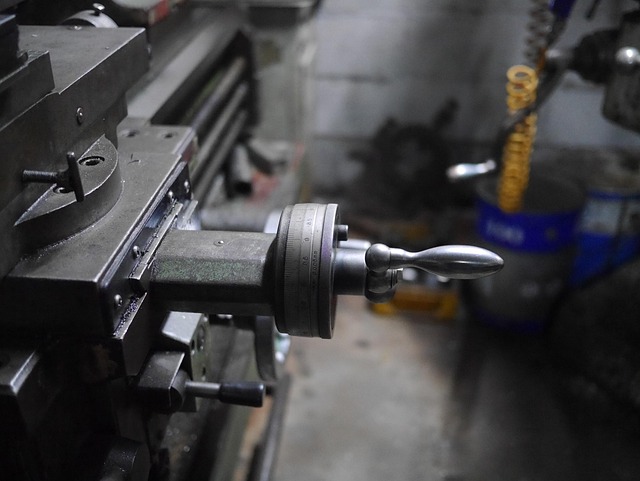

Tesla’s commitment to safety is well-documented, and a significant aspect of this is their stringent standards for material quality and manufacturing processes. One such critical area is Tesla aluminum welding certification, which ensures that every component undergoes rigorous testing to maintain structural integrity over the vehicle’s lifetime. This standard applies across various parts, from body panels to frames, using advanced techniques like laser welding to create seamless bonds.

The process involves specialized training for technicians and adherence to precise specifications to pass inspection. Tesla’s aluminum welding certification program is designed to uphold the highest quality control, ensuring that every vehicle undergoes thorough checks to prevent any potential issues related to auto body services or bodywork repairs. This emphasis on excellence in vehicle body repair reflects Tesla’s vision of creating durable, reliable, and safe electric vehicles for the future.

The Role of Certification in Ensuring Safety

The Tesla aluminum welding certification plays a pivotal role in ensuring long-term vehicle safety, especially for electric car models that boast advanced design and materials. This certification is more than just a stamp of approval; it guarantees that every weld on Tesla vehicles meets stringent industry standards. Skilled technicians, armed with this knowledge and expertise, can create robust bonds between aluminum components, enhancing structural integrity.

This process is crucial in mitigating potential hazards associated with car bodywork, including auto collision centers where repairs are frequent. With aluminum’s increasing use in automotive manufacturing, proper welding techniques become essential for maintaining the vehicle’s original performance and safety standards. It also simplifies subsequent tasks like auto glass replacement, ensuring that every repair complements the overall structural integrity of the car.

Longevity and Reliability: Benefits for Electric Vehicles

Electric vehicles (EVs), like their gasoline counterparts, require rigorous testing and high-quality construction to ensure longevity and reliability. One key aspect that sets EVs apart from traditional cars is the use of lightweight materials, such as aluminum, in their manufacturing. Tesla, a pioneer in the EV industry, understands this crucial factor for improving vehicle efficiency and safety.

The Tesla aluminum welding certification underscores the company’s commitment to excellence in automotive craftsmanship. By implementing rigorous standards and training for its welders, Tesla ensures that the structural integrity of its vehicles remains uncompromised over time. This is especially important for EVs, as their lightweight frames must withstand the rigors of daily driving while also meeting stringent safety regulations. Regular maintenance, including top-notch aluminum welding practices, plays a vital role in preserving the vehicle’s structural integrity and overall performance, ultimately contributing to a longer lifespan and better reliability compared to vehicles with less advanced manufacturing processes, such as those involving car dent repair or automotive body work.

Tesla’s commitment to innovation extends to its aluminum welding standards, which are now certified for long-term vehicle safety. This certification is a game-changer in the electric vehicle (EV) industry, ensuring that the intricate welds in Tesla vehicles meet rigorous quality and safety criteria. By adopting advanced welding techniques and obtaining this certification, Tesla reinforces its position as a leader in EV manufacturing, offering drivers peace of mind and contributing to the overall reliability and longevity of its vehicles.