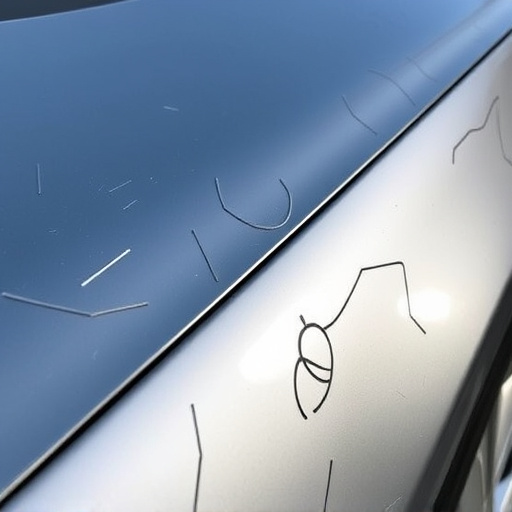

PDR (Paintless Dent Repair) is a revolutionary, non-invasive method for repairing dents and scratches on aluminum panels used in both industrial and automotive sectors. By preserving the original finish, PDR, tailored specifically for aluminum, maintains aesthetic appeal, avoids costly replacements, reduces vehicle downtime, and offers an eco-friendly solution compared to traditional methods like sandblasting or repainting. However, while minor damage often responds well, complex defects may require alternative approaches, emphasizing the importance of thorough inspection and consultation from experienced professionals.

In today’s automotive landscape, understanding the benefits of Paintless Dent Repair (PDR) for aluminum panels is crucial. This innovative technique offers a non-invasive approach to repairing dents and scratches on aluminum cars, preserving their pristine finish and enhancing their overall value. By employing PDR, auto body shops can provide efficient, cost-effective, and aesthetically superior repairs, catering to the growing demand for lightweight and durable materials like aluminum.

This article explores the advantages of PDR specifically tailored for aluminum panel repair, delving into best practices and tips to ensure optimal results.

- What is PDR and Why Aluminum Panels Benefit

- The Advantages of Using PDR for Aluminum Panel Repair

- Best Practices and Tips for Implementing PDR on Aluminum Panels

What is PDR and Why Aluminum Panels Benefit

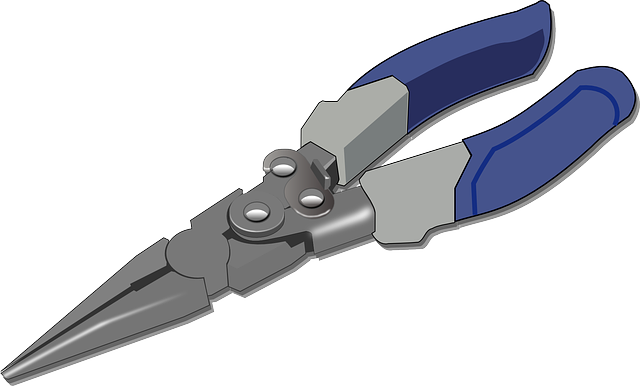

PDR, or Paintless Damage Repair, is a revolutionary technique that has transformed the way we address dents and scratches on various surfaces, including aluminum panels. This non-invasive method involves skilled technicians using specialized tools to gently work around the damaged area, restoring the panel to its original condition without the need for traditional painting or replacing the entire panel.

Aluminum panels, commonly used in both industrial and automotive applications, benefit immensely from PDR. Unlike other materials, aluminum is known for its versatility and lightweight properties, making it a popular choice in vehicle manufacturing. However, these panels are also susceptible to dents and dings, especially in car body shops or during transit. PDR offers an effective solution by preserving the original finish, maintaining the panel’s aesthetic appeal, and avoiding costly replacements. This technique is particularly advantageous for auto body restoration, ensuring vehicles return to their pre-accident condition while minimizing downtime and repair expenses.

The Advantages of Using PDR for Aluminum Panel Repair

Using PDR for aluminum panel repair offers numerous advantages over traditional methods. This non-invasive technique preserves the original factory finish, ensuring the repaired area seamlessly integrates with the rest of the vehicle. Unlike sandblasting or painting, PDR (Paintless Dent Repair) avoids damaging the metal surface or altering its protective coating.

This method is not only more environmentally friendly but also cost-effective. By minimizing material removal and eliminating the need for heavy chemicals or new paint, PDR reduces waste and labor costs associated with conventional car damage repair. Moreover, it significantly speeds up the restoration process, making vehicle repair services more efficient without compromising on quality.

Best Practices and Tips for Implementing PDR on Aluminum Panels

Implementing PDR (Paintless Dent Repair) on aluminum panels requires a careful approach to ensure optimal results and preserve the panel’s integrity. Best practices involve using specialized tools designed for non-metallic surfaces, as standard dent repair kits may not be suitable. It’s crucial to match the panel’s original finish precisely; this can often be achieved with advanced applicators that evenly distribute the filling compound.

Before beginning, thoroughly inspect the damage and assess its severity. Minor dents and dings typically respond well to PDR, but deeper or more complex defects may necessitate alternative auto body repair methods, such as traditional painting or replacement panels. Regular auto maintenance includes staying up-to-date with PDR techniques, as advancements in technology continue to improve the process’ effectiveness. For challenging cases, consult experienced professionals who specialize in both auto dent repair and vehicle body repair for aluminum vehicles.

PDR (Paintless Dent Repair) offers a highly effective and beneficial solution for repairing aluminum panels, ensuring their longevity and aesthetic appeal. By leveraging advanced techniques and tools, this method preserves the original finish while effectively removing dents and dings. The advantages are clear: reduced costs, minimal downtime, and an eco-friendly approach that minimizes waste. With the right practices and tips outlined, professionals can achieve exceptional results, making PDR a top choice for maintaining and restoring aluminum panels to their original condition.