Tesla aluminum PDR specialists employ advanced tools and meticulous techniques to repair and restore high-end vehicle body panels, maintaining structural integrity and aesthetic appeal while ensuring each car meets Tesla's stringent precision and quality standards.

Tesla’s adoption of aluminum for vehicle body panels has revolutionized automotive manufacturing. This shift presents unique challenges, especially during the Paint Damage Repair (PDR) process. This article explores the critical role of a Tesla aluminum PDR specialist in ensuring high-quality repairs. We delve into Tesla’s specialized PDR process, the expertise required for quality control, and advanced verification techniques that guarantee flawless results. Understanding these elements is key to maintaining the iconic Tesla finish.

- Understanding Tesla's Aluminum PDR Process

- Role of a Specialist in Quality Control

- Ensuring Excellence: Verification Techniques

Understanding Tesla's Aluminum PDR Process

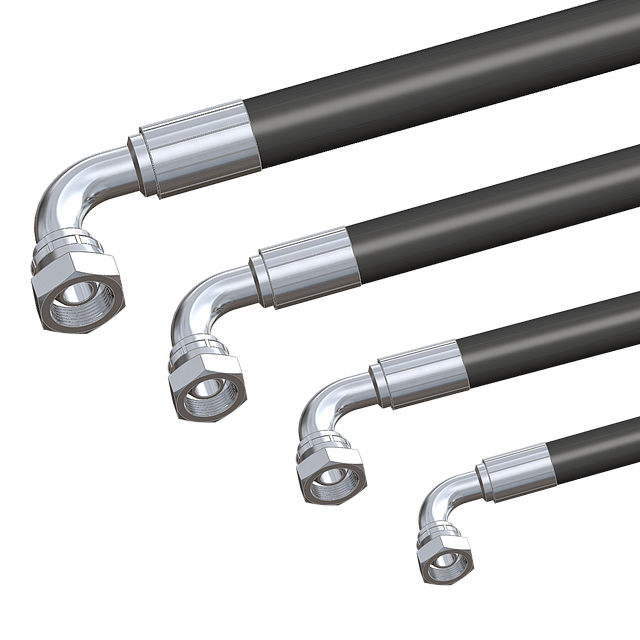

Tesla’s Aluminum PDR (Panel Replacement and Damage Repair) process is a meticulous art that requires the expertise of specialized technicians. This cutting-edge approach is revolutionizing auto glass repair, particularly for high-end vehicles like Mercedes Benz collision repair cases. The process starts with a thorough assessment to identify damage, followed by precise cutting and fitting of new aluminum panels, ensuring a seamless blend with the existing vehicle structure.

Specialists utilize advanced tools and techniques to minimize disruption to the car’s original design and finish. The attention to detail is remarkable, especially when considering classic car restoration projects. By mastering Tesla’s Aluminum PDR methods, professionals can deliver top-notch repairs, maintaining the vehicle’s integrity and aesthetic appeal, be it a modern electric vehicle or a vintage classic.

Role of a Specialist in Quality Control

In the intricate world of Tesla aluminum PDR (Panel Damage Repair) specialist and quality control verification, the role of a skilled professional cannot be overstated. A Tesla aluminum PDR specialist is a expert in their field, equipped with the knowledge and tools to meticulously assess, repair, and restore damaged car bodywork, focusing specifically on Tesla’s unique aluminum body panels. They are the guardians of quality, ensuring that every panel returned to the road meets Tesla’s stringent standards for precision and aesthetics.

These specialists play a pivotal role in preserving the integrity and value of Tesla vehicles. Beyond merely fixing dents and scratches, they conduct thorough inspections, employing advanced techniques like computer-aided design (CAD) and 3D scanning to verify repairs are precise and complete. This meticulous approach guarantees that every car leaving their shop not only looks as good as new but also performs optimally, showcasing the brand’s signature blend of innovation and craftsmanship. Whether dealing with minor fender benders or more extensive damage, a Tesla aluminum PDR specialist ensures that every repair is executed flawlessly, contributing to the overall satisfaction and safety of Tesla owners.

Ensuring Excellence: Verification Techniques

At a Tesla aluminum PDR specialist, ensuring excellence is paramount. Verification techniques play a crucial role in upholding the high standards set by both the brand and the skilled technicians. Through meticulous inspection and advanced technology, every repair is scrutinized to match the precision and quality of the original manufacturing processes. This involves careful assessment of panel alignment, paint consistency, and overall structural integrity – all vital aspects when it comes to car bodywork services.

The expertise of a Tesla aluminum PDR specialist extends beyond mere repairs; it encompasses comprehensive quality control verification. This includes utilizing specialized tools to detect even the subtlest imperfections, such as dents or scratches, in the vehicle dent repair process. By implementing these rigorous verification methods, the specialist guarantees that each car body shop job is not merely satisfactory but exceptional, reflecting the craftsmanship and attention to detail expected from Tesla’s brand identity.

Tesla’s commitment to quality is evident in their rigorous aluminum PDR (Panel Replacement Door) process, where specialists play a pivotal role. These experts ensure that each door undergoes thorough verification, from material inspection to precision fitting. By employing advanced techniques, they maintain the superior craftsmanship and sleek design for which Tesla is renowned, making every replacement as good as new. This level of dedication guarantees that drivers experience not just a repair, but an exceptional restoration that keeps their vehicles looking vibrant and original.