Proper OEM glass replacement requires meticulous surface preparation, including cleaning and addressing damage, using suitable tools like sandpaper. Selecting UV-resistant silicone sealant for standard installations offers durability. In collision repair, structural bonding sealants ensure strong adhesion. Correct application and curing, following manufacturer guidelines, maintain sealant integrity for long-lasting, water-tight seals in car collision repair and auto body work.

When replacing original equipment manufacturer (OEM) glass, applying proper sealants ensures a secure, durable fit. This guide breaks down the process into three essential steps: preparing the surface for optimal adhesion, selecting the right sealing compound, and applying & curing the sealant effectively. By following these straightforward instructions, you’ll achieve a professional-quality OEM glass replacement, enhancing safety and aesthetics alike.

- Prepare Surface for Optimal Adhesion

- Choose the Right Sealing Compound

- Apply and Cure Sealant Effectively

Prepare Surface for Optimal Adhesion

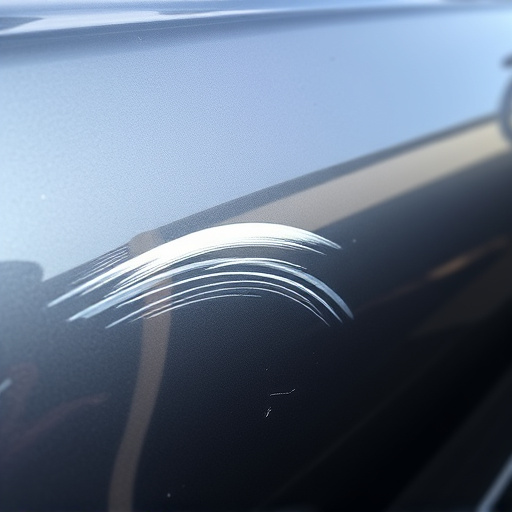

Before applying any sealant, preparing the surface is paramount for achieving optimal adhesion when conducting an OEM glass replacement. This involves thoroughly cleaning and decontaminating the area to ensure no dirt, grease, or wax residues are present. A simple solution of warm water and a mild detergent, followed by a thorough rinse and drying, can effectively remove any contaminants. It’s also crucial to address any existing damage like cracks or rough spots, as these imperfections can hinder sealant bonding.

Using the right tools for the job, such as fine-grit sandpaper to smooth out rough surfaces, is essential in achieving a seamless finish. In the case of Mercedes Benz repair or general auto maintenance, addressing surface preparation correctly sets the stage for a durable and long-lasting sealant application, contributing to the overall quality of the OEM glass replacement process.

Choose the Right Sealing Compound

When it comes to installing OEM glass, selecting the appropriate sealing compound is paramount for a successful and long-lasting result. The right sealant acts as a crucial bond between the glass and the vehicle’s structure, ensuring water tightness and preventing leakage. For an OEM glass replacement, consider using a high-quality, UV-resistant silicone sealant that offers superior flexibility and durability. This type of sealant is ideal because it can withstand temperature changes, which are common in vehicle bodies, without losing its integrity.

Choosing the correct compound also depends on the specific application. In a vehicle collision repair or paint repair scenario, where the glass may be replaced due to damage, an adhesive sealant designed for structural bonding might be more suitable. These compounds provide strong adhesion and often come with added benefits like resistance to chemicals and UV rays, ensuring the new glass is protected and secure within the vehicle body shop’s environment.

Apply and Cure Sealant Effectively

Applying and curing sealants properly is a critical step in ensuring the longevity and integrity of OEM glass replacements. After carefully preparing the surface and applying the chosen sealant, it’s crucial to allow it to cure fully before subjecting the area to any stress or pressure. This process involves more than just leaving it untouched; it requires understanding the specific curing requirements of the sealant used, which often includes maintaining a certain temperature range and avoiding direct exposure to moisture or sunlight during the initial stages.

For optimal results in car collision repair or auto body repairs involving OEM glass replacement, allow the sealant to cure according to the manufacturer’s instructions. This may involve using heat sources, such as hair dryers on low settings, to accelerate the process while ensuring it doesn’t exceed the recommended temperature threshold. Once cured, the sealant forms a protective barrier, enhancing the bond between the glass and the vehicle’s structure, thus improving overall durability and performance, just as it would in a meticulously executed car restoration project.

When performing an OEM glass replacement, proper sealing is crucial for both the durability of the installation and the safety of the vehicle. By preparing the surface correctly, selecting the right sealant compound, and applying it effectively, you can ensure a secure fit that stands up to various weather conditions. Remember, a well-sealed glass panel enhances the overall quality of the repair, providing long-lasting protection for both the vehicle and its occupants.