Frame repair technology revolutionizes auto body shops by automating damage assessment, calculation, and measurement, reducing repair times and labor costs. Using advanced tools like CAD software and robotic welders, technicians precisely repair frames while minimizing rework. This digital approach streamlines processes, enhances efficiency, and saves money for businesses and consumers alike.

Frame repair technology is transforming the automotive industry, offering a faster, more cost-effective solution for damaged vehicle frames. This advanced system streamlines the repair process, reducing labor hours and minimizing part replacement costs. By understanding the fundamentals of frame repair technology and its benefits, auto shops can implement this game-changing tech to enhance efficiency and stay competitive in today’s market. Explore these strategies to leverage frame repair technology for optimal results.

- Understanding Frame Repair Technology: The Basics

- Benefits of Advanced Frame Repair Systems

- Implementing Frame Repair Tech: Strategies and Tips

Understanding Frame Repair Technology: The Basics

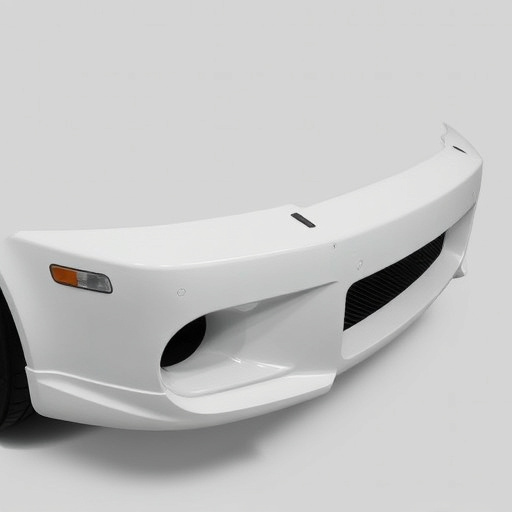

Frame repair technology has revolutionized vehicle collision repair, offering a faster and more efficient solution for both technicians and customers. At its core, this innovative approach involves specialized equipment and precision techniques to mitigate damage to a vehicle’s frame, which is often the most critical component in a car’s structure. By employing advanced tools like robotic welders and computer-aided design (CAD) software, technicians can accurately assess and repair dents and misalignments caused by accidents or impacts.

This technology streamlines the dent repair process, significantly reducing the time typically spent on manual labor. Traditional frame repairs often required intricate measurements and adjustments, a task that could take days or even weeks. With frame repair technology, these processes are digitized, enabling faster and more precise results. Consequently, car paint services can be better integrated into the overall restoration, ensuring a seamless finish that restores the vehicle to its pre-accident condition, all while minimizing labor costs for auto body shops.

Benefits of Advanced Frame Repair Systems

The advancements in frame repair technology have brought about significant advantages for both automotive body shops and vehicle owners. One of the key benefits is the substantial reduction in repair time. Traditional frame repairs often involved intricate manual labor, leading to longer turnaround periods. However, modern systems streamline the process by utilizing advanced tools and techniques. Automated systems can quickly identify damage, calculate repairs, and provide precise measurements, ensuring faster and more efficient work.

Additionally, these innovative technologies minimize labor costs. By automating repetitive tasks, automotive body shops can reduce their reliance on extensive manual labor, which is often the most significant expense in car body repair. This not only benefits businesses by increasing profitability but also offers customers more affordable repair options. With frame repair technology, vehicle owners can expect quicker turnarounds and potentially lower bills for their car body shop visits.

Implementing Frame Repair Tech: Strategies and Tips

Implementing Frame Repair Tech involves a strategic approach to maximize efficiency and minimize costs. One key strategy is training. Ensuring that technicians are well-versed in the latest frame repair technology, including computer-aided design (CAD) software and advanced measurement tools, is vital. This allows them to accurately assess and correct collision damage, reducing the need for costly rework.

Additionally, shops should invest in high-quality equipment tailored to frame repair. This includes specialized tools like robotic welding machines, precision measuring devices, and frame straighterners. Standardizing on these tools ensures consistency and efficiency in autobody repairs. Incorporating digital documentation and cloud-based systems can also streamline processes, facilitating better tracking of vehicle history and reducing manual errors commonly associated with traditional paper-based record-keeping, thereby contributing to overall cost savings in collision damage repair.

Frame repair technology has proven to be a game-changer in the automotive industry, offering significant advantages in terms of reduced repair time and labor costs. By implementing advanced systems and strategies, mechanics can streamline the frame repair process, leading to increased efficiency and cost savings for both repair shops and vehicle owners. This innovative approach to auto maintenance is reshaping the way we address structural damage, ensuring safer and more affordable repairs for all.