TIG welding auto body offers technicians precise control for intricate repairs, ideal for complex bodywork and diverse materials like steel, aluminum, and titanium. It excels in structural fixes and cosmetic enhancements, ensuring superior repair quality, precision, strength, and aesthetic appeal while streamlining workflows.

TIG welding auto body has emerged as a game-changer for auto technicians, offering unparalleled precision and control in repairs. This article explores the multifaceted benefits of this advanced technique, including its versatility in joining and repairing diverse materials, and its ability to enhance the strength and durability of car bodies. By leveraging TIG welding, technicians can achieve superior results, ensuring vehicles not only look their best but also perform optimally on the road.

- Enhanced Precision and Control for Auto Repairs

- Versatility in Material Joining and Repair

- Improved Strength and Durability of Car Bodies

Enhanced Precision and Control for Auto Repairs

TIG welding auto body offers auto technicians an unparalleled level of precision and control when undertaking repairs. Unlike traditional welding methods, TIG (Tungsten Inert Gas) welding allows for precise manipulation of heat input, enabling technicians to make intricate adjustments during the welding process. This enhanced control is particularly beneficial in complex vehicle bodywork scenarios where maintaining structural integrity while achieving a seamless finish is paramount.

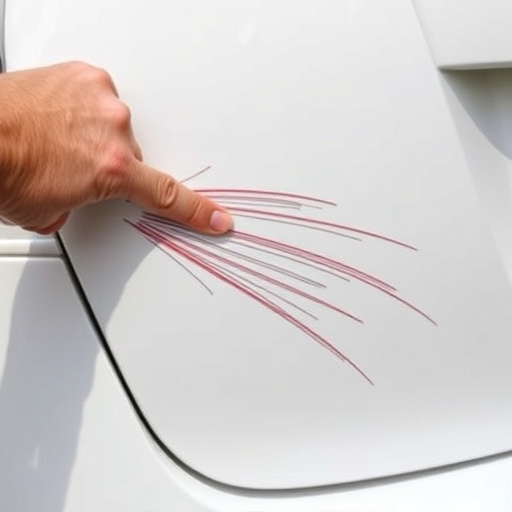

For auto collision centers and their skilled technicians, TIG welding translates to more effective scratch repair and restoration of vehicle bodywork. Its versatility allows for both heavy-duty structural repairs and meticulous finishing touches, ensuring that every vehicle leaves the shop looking like new. This advanced technique not only boosts the overall quality of auto body repairs but also streamlines the process, saving time and resources in the long run.

Versatility in Material Joining and Repair

TIG welding auto body is a versatile technique that allows technicians to seamlessly join and repair various materials commonly found in vehicle body shops. This method is particularly beneficial for fender repair and classic car restoration projects, where precision and strength are paramount. By using TIG welding, technicians can work with different metals, including steel, aluminum, and even titanium, ensuring durable and aesthetically pleasing results.

The versatility of TIG welding extends to its ability to handle intricate designs and complex geometries. This makes it ideal for both structural repairs and cosmetic enhancements, providing a single solution for various challenges encountered during fender repair or classic car restoration processes.

Improved Strength and Durability of Car Bodies

TIG welding auto body is renowned for significantly enhancing the strength and durability of vehicle structures. This highly precise and specialized technique fuses metal components together with exceptional precision, creating robust bonds that withstand significant stress and pressure. By employing TIG welding, car repair shops can ensure that the rebuilt or repaired sections of a car’s body are as strong as, if not stronger than, the original manufacturing standards.

This enhanced structural integrity is particularly beneficial for dent repair and car paint repair processes. When dealing with damaged panels, TIG welding allows technicians to precisely fill in gaps and contours while maintaining structural soundness. The result is a seamless fusion that leaves no trace of previous damage, ensuring both aesthetic appeal and long-term functional reliability.

TIG welding auto body offers a game-changing approach for auto technicians, combining enhanced precision, versatility, and superior strength. By mastering this technique, professionals can elevate their repair and restoration skills, ensuring durable and visually appealing outcomes. Incorporating TIG welding into automotive practices is a step towards revolutionizing the industry, providing both functional and aesthetic advantages that cater to modern vehicle demands.