Metal panel dent repair for steel and aluminum vehicles involves techniques from manual pushing to advanced "Paintless Dent Repair" (PDR). Skilled professionals use specialized tools like air compressors, dent pullers, and mallets to achieve precise, seamless repairs. The process includes assessing damage, gathering supplies, popping the dent, shaping, filling, sanding, and optional painting. High-quality tools are key for matching original finishes, benefiting both professionals and DIY enthusiasts in metal panel dent repair.

“Discover the art of metal panel dent repair, a crucial skill for maintaining your vehicle’s aesthetic appeal. This comprehensive guide delves into the techniques tailored for aluminum and steel vehicles. From understanding the unique challenges of each metal type to mastering efficient repair methods, you’ll explore powerful tools and gain a step-by-step approach.

Learn how to transform dented panels into flawless finishes, ensuring your vehicle stands out in the hustle and bustle of daily driving.”

- Understanding Metal Panel Dent Repair Techniques

- Tools and Equipment for Efficient Repair

- Step-by-Step Guide to Fixing Aluminum and Steel Dents

Understanding Metal Panel Dent Repair Techniques

Metal panel dent repair is a specialized technique crucial for restoring the aesthetic and structural integrity of both steel and aluminum vehicles. This process involves various methods tailored to address different types and sizes of dents, from minor scuffs to significant deformities. Understanding these techniques is key in ensuring effective car body repair. One common approach is the use of specialized tools like picks and hammers to gently push the dented panel back into its original shape without causing further damage or compromising the metal’s strength.

For more severe cases, a method known as “PDR” (Paintless Dent Repair) is employed. PDR utilizes advanced tools that can reach and manipulate the inner surface of the panel from behind, allowing for a precise and seamless restoration. This technique is not only efficient but also cost-effective compared to traditional auto maintenance methods. By mastering these metal panel dent repair techniques, professionals can effectively address car scratch repair and ensure vehicles return to their pre-dent condition, enhancing both their appearance and value.

Tools and Equipment for Efficient Repair

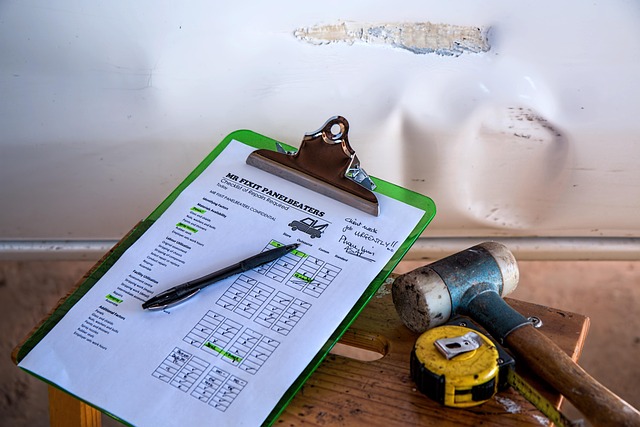

The success of metal panel dent repair, whether for aluminum or steel vehicles, heavily relies on the tools and equipment used. For efficient and effective repairs, professionals rely on a variety of specialized tools designed to handle different types and sizes of dents. These include powerful air compressors, which provide the necessary pressure for pneumatic tools like dent pullers and pounders, allowing precise control over the repair process. Additionally, handheld tools such as mallets, clamps, and scrapers ensure meticulous removal of damaged panels, preparing the surface for patching or painting.

Investment in high-quality tools is crucial for achieving seamless results that match the vehicle’s original finish. Advanced tools offer greater accuracy, faster repair times, and improved control, ultimately streamlining auto maintenance processes. This not only benefits professional auto repair services but also empowers enthusiasts to undertake fender repairs themselves with more confidence and precision.

Step-by-Step Guide to Fixing Aluminum and Steel Dents

Repairing aluminum and steel dents on your vehicle is a process that can be accomplished with the right tools and techniques. Here’s a step-by-step guide to help you get started with metal panel dent repair.

1. Assess the Damage: Begin by inspecting the dent carefully. Determine its size, depth, and location on the vehicle body. Different areas of the car have varying levels of flexibility, which will impact how the dent is repaired. Aluminum and steel both respond uniquely to pressure, so understanding these variations is key.

2. Gather Your Supplies: You’ll need specific tools for this job—a dent puller or a hammer with a rubber mallet, along with some high-quality putty knives and a metal panel repair kit. Ensure you have access to a clean, well-lit workspace at an automotive body shop or collision center.

3. Preparation: Before beginning the repair, ensure the area around the dent is cleaned and free of debris. Mask off surrounding areas with tape to prevent accidental damage during the process.

4. Popping the Dent: Using the appropriate tool, carefully apply pressure behind the dent to pop it out. This step requires precision and patience, especially with aluminum, as over-pressurizing can cause further damage or deform the panel.

5. Shaping and Smoothening: Once the dent is popped out, use putty knives to shape and smooth the surrounding area. This process involves carefully removing excess metal and blending it seamlessly with the car’s original surface.

6. Filling and Sanding: Apply the metal repair compound and let it dry as per the product instructions. Then, gently sand the repaired area until it’s even with the vehicle’s body panels. Ensure you use the right grit sandpaper for a smooth finish.

7. Painting (if required): If there are paint imperfections due to the dent, touch up the paint job using a color-matched aerosol can. Allow the paint to dry completely before reassembling any removed parts.

Metal panel dent repair is a skilled technique that can restore both aluminum and steel vehicles to their original condition. By understanding the various methods, investing in the right tools, and following a systematic approach, auto enthusiasts and professionals alike can achieve impressive results. This guide has provided insights into the essentials of metal panel dent repair, ensuring that anyone with the desire and proper knowledge can tackle dents effectively.