Addressing repair quality concerns through proactive measures like training, communication, and equipment investment is crucial for automotive shops. Gaps in training, communication, and materials lead to visible work disparities and potential safety issues. Best practices include rigorous technician training, transparent communication, and clear estimates. Real-world examples show that strategic interventions improve repair quality, enhance customer satisfaction, and foster loyalty.

In today’s complex manufacturing landscape, ensuring repair quality is paramount. This article delves into the critical issue of repair quality concerns and offers actionable insights for manufacturers. We first uncover common challenges, from inconsistent part replacement to lack of proper training, that often lead to resolution issues. Next, we explore industry best practices proven to mitigate these problems. Finally, real-world success stories highlight effective strategies, demonstrating how organizations have transformed their repair quality through innovative approaches and data-driven decisions.

- Uncovering Common Repair Quality Concerns

- Industry Best Practices for Resolution

- Real-World Success Stories of Quality Improvements

Uncovering Common Repair Quality Concerns

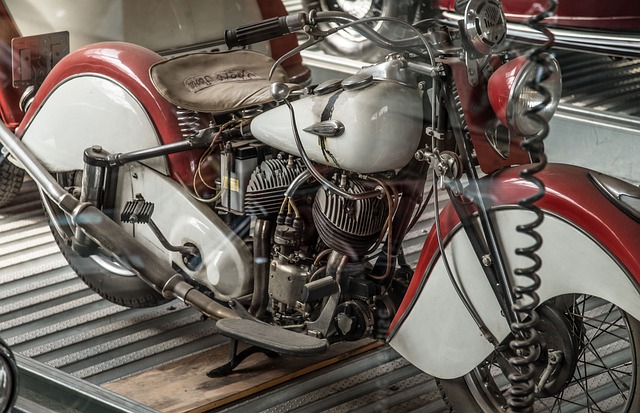

In the realm of automotive maintenance, ensuring repair quality is paramount to customer satisfaction and safety. Common repair quality concerns often arise from miscommunication between customers and repair shops, inadequate training among technicians, or subpar materials used in the fixing process. These issues manifest as visible disparities in work quality, such as uneven paint jobs resulting from car paint services, or structural weaknesses lingering after car body repair sessions. Unaddressed, these problems can lead to further damage, unsafe driving conditions, and a loss of trust between customers and body shop services.

Moreover, repairs that fail to meet industry standards can reflect poorly on both the repair shop and the brand, impacting business reputation and customer loyalty. Therefore, proactive measures are necessary to uncover and rectify these concerns. Regular quality checks, transparent communication channels, and continuous training programs for technicians in various body shop services are critical steps towards ensuring optimal repair quality across the board, be it for car paint services or more intricate car body repair tasks.

Industry Best Practices for Resolution

In addressing repair quality concerns, the automotive industry has established a set of best practices that serve as a gold standard for auto repair services and car scratch repair. These practices prioritize customer satisfaction and ensure the highest level of craftsmanship in every aspect of car repair services. One key practice is implementing rigorous training programs for technicians to maintain up-to-date skills and knowledge, specifically focusing on techniques for minor dent removal and panel restoration, such as those needed for car scratch repair.

Additionally, industry leaders emphasize clear communication with customers throughout the repair process. This includes providing detailed estimates, explaining every step of the repair, and ensuring customer approval before proceeding with any work. By fostering transparency, auto repair services can build trust and guarantee that clients are comfortable with the quality of repairs, ultimately enhancing the overall customer experience.

Real-World Success Stories of Quality Improvements

In the realm of repairing quality concerns, numerous real-world success stories highlight the transformative power of proactive measures and innovative solutions. One such example involves a leading automotive manufacturer grappling with consistent issues in their vehicle repair processes. After conducting an in-depth analysis, they identified a gap in communication between different departments, leading to misaligned expectations and subpar results. To address this, they implemented a comprehensive training program focused on improving interdepartmental collaboration. This strategic move resulted in enhanced repair quality, reduced turnaround times, and increased customer satisfaction for their vehicle repair services.

Another inspiring narrative centers around a local auto glass replacement shop that experienced high rates of customer complaints due to imperfect installations. Recognizing the issue, they invested in state-of-the-art equipment and hired certified technicians specialized in auto glass repair. By adopting these improvements, the shop not only significantly decreased repair flaws but also fostered a culture of excellence. Customers praised the meticulous craftsmanship in their car restoration processes, leading to a surge in repeat business and positive reviews, solidifying their position as a trusted provider of top-quality vehicle repair services.

In addressing real cases of repair quality concerns, it’s evident that a combination of proactive identification and industry best practices can lead to substantial improvements. By understanding common issues and implementing effective resolution strategies, businesses can enhance customer satisfaction and maintain high standards. The success stories highlighted in this article serve as a testament to the positive outcomes achievable when focusing on repair quality—a crucial aspect for any service-oriented industry.