Factory tolerance restoration is a precise process that brings machinery and equipment back to original specifications, reducing repair cycle times and ensuring maximum precision. In automotive sectors, this technique enhances efficiency, safety, and structural integrity, streamlining operations, minimizing costs, and boosting customer satisfaction by enabling faster turnaround times.

Factory tolerance restoration is a game-changer in optimizing production efficiency. This process aims to minimize repair times by addressing inherent manufacturing variations, ensuring components fit together seamlessly. In today’s competitive market, understanding and implementing effective factory tolerance restoration techniques can significantly reduce downtime. By delving into the basics and exploring key benefits, this article guides you through strategies to enhance productivity, offering a roadmap for successful factory tolerance restoration.

- Understanding Factory Tolerance Restoration Basics

- Key Benefits of Reducing Repair Cycle Times

- Implementing Strategies for Efficient Restoration

Understanding Factory Tolerance Restoration Basics

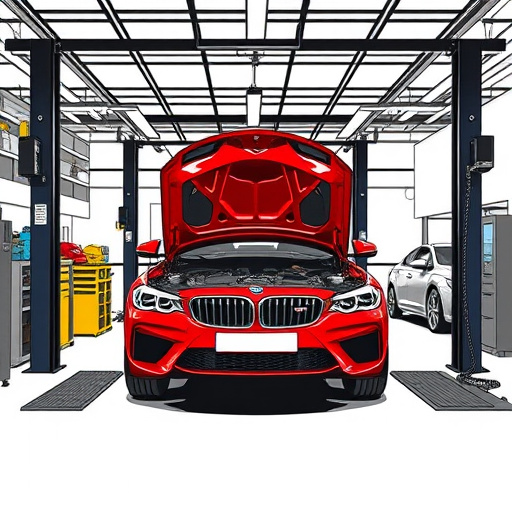

Factory Tolerance Restoration is a meticulous process designed to bring machinery and equipment back to their original specifications after wear and tear or repairs. This advanced technique involves carefully adjusting and calibrating components within a manufacturing facility, ensuring every part operates with maximum precision. By restoring these tolerances, factories can significantly reduce repair cycle times, as issues related to misalignment or inconsistent performance are minimized.

For auto repair near me or fleet repair services, maintaining tight tolerances is crucial for maintaining vehicle efficiency and safety standards. Similarly, in the realm of automotive body work, precise factory settings ensure structural integrity, leading to faster turnaround times without compromising quality. This method not only streamlines operations but also enhances overall equipment effectiveness, making it a valuable asset for any well-oiled manufacturing or auto repair shop.

Key Benefits of Reducing Repair Cycle Times

Reducing repair cycle times through factory tolerance restoration offers numerous advantages for both manufacturers and customers. One of the primary benefits is increased operational efficiency; when repairs are completed faster, production lines can maintain a steady pace, minimizing delays and maximizing output. This is particularly crucial in competitive markets where speed to market is a key differentiator.

Additionally, shorter repair cycle times translate into cost savings for automotive body shops and classic car restoration specialists. By streamlining the process, these businesses can reduce labor costs, optimize resource utilization, and potentially offer more competitive pricing without compromising quality. Faster turnarounds also enhance customer satisfaction, as owners receive their vehicles back in less time, ensuring a smoother and more convenient experience. This efficiency boost, driven by factory tolerance restoration techniques, is a game-changer for the industry, revolutionizing how automotive repairs are handled.

Implementing Strategies for Efficient Restoration

Implementing effective strategies for factory tolerance restoration is a game-changer in any car body shop or collision repair facility. This process involves meticulous techniques to ensure components align precisely, resulting in superior quality repairs. By focusing on restoration rather than solely replacement, fender repair and other similar tasks become more efficient.

Professional technicians utilize specialized tools and knowledge to realign parts within strict tolerances, eliminating the need for excessive material removal or additional modifications. This approach not only reduces repair cycle times but also minimizes the risk of compromising the structural integrity of the vehicle. Efficient factory tolerance restoration is a key differentiator in modern collision repair, ensuring that cars return to their pre-incident condition faster and safer.

Factory Tolerance Restoration (FTR) is a powerful strategy that significantly reduces repair cycle times, enhancing overall operational efficiency. By understanding the fundamentals and implementing effective restoration strategies, manufacturers can achieve faster turnaround times, minimize downtime, and optimize their production processes. FTR’s key benefits include improved part consistency, reduced scrap rates, and enhanced productivity, ultimately leading to cost savings and increased competitiveness in today’s market.