Squeeze-type resistance spot welding strengthens modern vehicles' critical components during collisions, enhancing airbag deployment and sensor functionality. This precise technique ensures structural integrity and reliable operation under extreme conditions, thereby improving auto glass replacement effectiveness and overall vehicle safety. It's vital for maintaining sensor integrity and minimizing malfunction or false readings, preserving bodywork and component durability.

“In the automotive industry, ensuring the integrity of airbag deployment and sensor functionality is paramount for passenger safety. Squeeze-type resistance spot welding (SRSW) plays a pivotal role in achieving this. This advanced welding technique offers unparalleled precision and strength, critical for joining components that must withstand extreme forces during airbags’ rapid deployment.

This article explores SRSW basics, its impact on airbag seams, and how it guarantees the reliability of sensors, ultimately contributing to enhanced vehicle safety.”

- Understanding Squeeze-Type Resistance Spot Welding Basics

- Airbag Deployment: The Critical Role of Seam Strength

- Sensor Integrity Assurance Through Advanced Welding Techniques

Understanding Squeeze-Type Resistance Spot Welding Basics

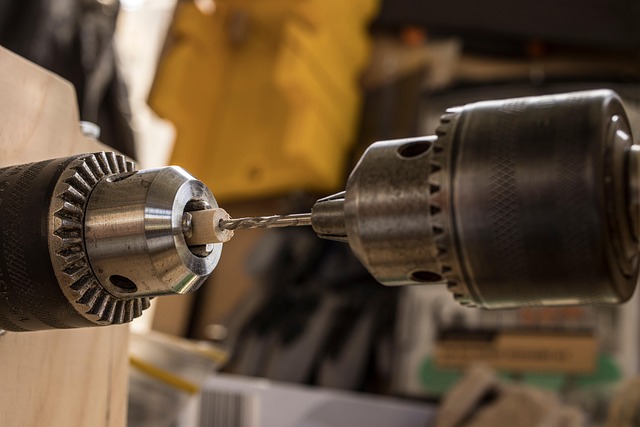

Squeeze-type resistance spot welding is a specialized process that plays a critical role in ensuring the integrity and reliability of key components in modern vehicles, especially during emergency situations like car collisions. This technique involves applying precise pressure and heat to create a robust bond between metal surfaces, often in tight or complex geometries. By focusing intense energy on specific spots, it enables manufacturers to join thin sheets of metal with exceptional strength and accuracy.

In the context of airbag deployment and sensor functionality, squeeze-type resistance spot welding guarantees the structural soundness of vehicle frames and components. This is vital during a car collision repair, where the quick and reliable deployment of airbags can be a matter of life and death. Similarly, sensors that detect crash impact and trigger safety mechanisms are securely fastened using this method, ensuring their functional integrity even under extreme conditions, thereby enhancing overall auto glass replacement and repair effectiveness.

Airbag Deployment: The Critical Role of Seam Strength

Airbag deployment is a crucial safety feature in modern vehicles, designed to protect occupants during collisions. The effectiveness of airbags heavily relies on the integrity and strength of their seams, which are created using specialized techniques like squeeze-type resistance spot welding. This method ensures that the airbag material is precisely fused together, creating a robust seal that can withstand extreme forces during deployment.

In the event of a collision, the rapid inflation of airbags requires seamless construction. Weak or improperly welded seams could lead to catastrophic failure, rendering the airbag ineffective and potentially causing further collision damage repair. Auto repair shops emphasize the importance of high-quality welding techniques, such as squeeze-type resistance spot welding, to ensure the structural integrity of these vital safety components, thereby enhancing the overall protection offered by modern vehicles.

Sensor Integrity Assurance Through Advanced Welding Techniques

In the automotive industry, ensuring sensor integrity is paramount for safety and functionality. Squeeze-type resistance spot welding plays a pivotal role in maintaining this integrity. This advanced welding technique offers unparalleled precision and strength, directly contributing to the reliability of sensors crucial for airbags and other critical systems. By creating clean, consistent welds, it minimizes the risk of sensor malfunction or false readings, which could have severe consequences in vehicle safety.

Moreover, squeeze-type resistance spot welding facilitates the integration of miniaturized sensors into tight, complex spaces within modern vehicles. This is particularly important as automotive technology evolves, requiring smaller, more efficient components. Unlike traditional welding methods, this technique allows for localized heating and precise control, preserving the structural integrity of surrounding materials, including delicate vehicle bodywork and auto glass replacement components. Thus, it ensures not just functional sensors but also the overall durability and safety of the vehicle.

Resistance Spot Welding, particularly its advanced squeeze-type techniques, plays an indispensable role in ensuring the integrity and reliability of airbags and sensors in modern vehicles. By enhancing seam strength and precision, these welding methods contribute to safer deployment of airbags and accurate sensor functionality, ultimately saving lives and protecting passengers. The ongoing development and adoption of these advanced welding techniques underscore their significance in the automotive industry’s quest for enhanced safety and performance.