Safety sensor recalibration is a critical, often overlooked aspect of vehicle maintenance, crucial for advanced driver-assistance systems (ADAS) performance and safety. Legal requirements and warranty terms mandate regular recalibration to avoid severe consequences, including legal liability and voided coverage. Proactive consumer involvement ensures optimal sensor accuracy and sensitivity, enhancing overall vehicle safety and reliability.

In many industries, safety sensor recalibration is not just a best practice—it’s a legal requirement. This is especially true for critical systems where accurate sensors can mean the difference between life and death. Non-compliance with calibration standards can lead to severe consequences, including fines, equipment failure, and even liability issues. This article explores the legal and warranty implications of inadequate sensor recalibration, while offering best practices for regular and precise safety sensor recalibration to mitigate risks and ensure optimal system performance.

- Understanding Safety Sensor Recalibration Requirements

- Legal and Warranty Implications of Inadequate Calibration

- Best Practices for Regular and Accurate Sensor Recalibration

Understanding Safety Sensor Recalibration Requirements

Safety sensor recalibration is a critical aspect of vehicle maintenance that often falls under the radar for many car owners and even some automotive professionals. Understanding when and why it’s required is essential, as it plays a pivotal role in ensuring the safety features of your vehicle function optimally. Recalibration is generally necessitated by two primary factors: legal requirements and warranty terms.

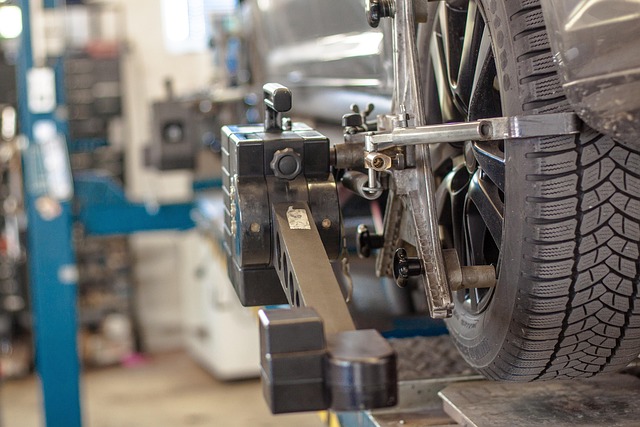

In many jurisdictions, there are strict regulations mandating regular checks and adjustments for safety sensors, especially in modern vehicles equipped with advanced driver-assistance systems (ADAS). These sensors include lane departure warnings, adaptive cruise control, and automatic emergency braking, among others. Furthermore, automotive manufacturers often include recalibration as part of the standard warranty coverage, ensuring that any potential drift or malfunction in these sensitive systems is corrected promptly. For instance, if a car has undergone a severe collision or significant frame straightening during an automotive restoration process, it’s crucial to realign and recalibrate safety sensors to maintain their effectiveness.

Legal and Warranty Implications of Inadequate Calibration

Inadequate safety sensor recalibration can have significant legal and warranty implications for both manufacturers and consumers alike. When safety sensors, such as those found in modern vehicles, fail to meet their calibrated performance due to neglect or improper maintenance, it compromises the overall safety of the vehicle. This is particularly critical in the event of an automotive collision repair, where accurate sensor readings are vital for deploying airbags and other safety systems appropriately.

In many cases, warranties explicitly state that regular maintenance, including safety sensor recalibration, is the responsibility of the owner to prevent voiding coverage. Moreover, legal precedents have established that manufacturers can be held liable for accidents resulting from defective or improperly calibrated sensors, especially if there was negligence in adhering to recommended calibration intervals. This underscores the importance of consumers being proactive about scheduling body shop services that include safety sensor recalibration as part of their car dent removal and other routine maintenance routines.

Best Practices for Regular and Accurate Sensor Recalibration

Regular and accurate safety sensor recalibration is a best practice for maintaining optimal vehicle performance and ensuring the safety of all occupants. This process involves periodically adjusting the sensitivity and accuracy of sensors responsible for detecting potential hazards, such as collisions or obstacles. Following a structured schedule, often recommended by manufacturers, allows for proactive management of these critical systems. Regular calibration ensures that sensors function at peak efficiency, enhancing overall vehicle safety and reliability.

To achieve accurate recalibration, it’s essential to follow specific procedures tailored to each sensor’s type and location. For instance, recalibrating sensors within the bumper or vehicle bodywork requires precise techniques to account for potential damage during auto maintenance or repairs. This meticulous approach guarantees that any adjustments made align with the vehicle’s structural integrity and safety standards, ultimately contributing to a safer driving experience.

Safety sensor recalibration is not just a best practice; it’s often legally mandated and a crucial component of product warranties. The implications of inadequate calibration can be severe, from legal consequences to potential safety hazards. By understanding the requirements, recognizing the importance, and adopting regular, accurate recalibration practices, manufacturers can ensure their products meet safety standards, comply with regulations, and maintain customer trust. This proactive approach not only protects against legal issues but also enhances product reliability and user safety.