Safety is paramount in plastic panel repair and replacement, with strict regulations protecting individuals and vehicles. Auto collision centers, staffed by skilled technicians, follow industry-approved practices, material compatibility, and proper application techniques to ensure structural integrity and longevity. This guide offers a range of solutions from DIY kits to professional services, empowering you to decide whether to tackle repairs yourself or seek expert help. Prioritizing long-term safety and environmental compliance through adherence to industry standards, approved materials, and technician training minimizes risks and guarantees seamless plastic panel repair and replacement outcomes.

“In today’s world, ensuring safety during plastic panel repair and replacement is paramount for structural integrity and user well-being. This comprehensive guide delves into the essential safety regulations surrounding these processes. From understanding industry standards to best practices, we explore effective strategies. We also highlight long-term safety measures, emphasizing compliance as a cornerstone of quality work. By adhering to these guidelines, professionals can ensure robust, safe solutions for plastic panel repair and replacement.”

- Understanding Plastic Panel Safety Standards

- Best Practices for Repair and Replacement Procedures

- Ensuring Long-Term Safety and Compliance

Understanding Plastic Panel Safety Standards

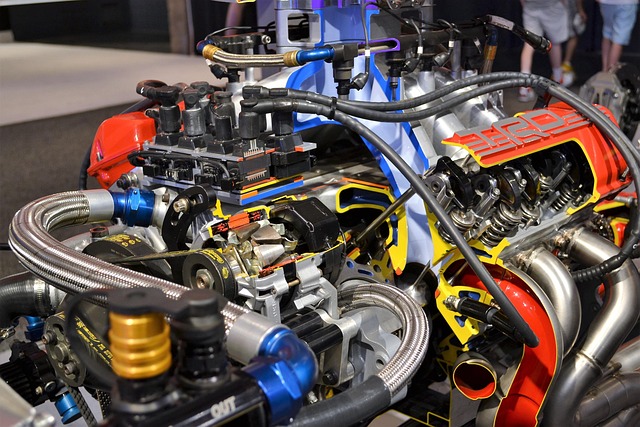

When it comes to plastic panel repair and replacement, adhering to safety standards is paramount. These regulations are designed to ensure that both the process and the final product meet specific safety criteria, protecting individuals and vehicles alike. Understanding these standards involves familiarizing yourself with industry-approved practices, material compatibility, and proper application techniques. For instance, using authentic, high-quality materials from certified suppliers ensures structural integrity and longevity, especially in cases of auto collision centers handling plastic panel repair.

In the realm of vehicle repair, including car scratch repair, safety standards require meticulous attention to detail. This involves not only correct identification of parts but also adherence to manufacturer guidelines during replacement. Skilled technicians in auto collision centers are trained to navigate these labyrinthine regulations, ensuring that every plastic panel repair or replacement is carried out effectively and securely.

Best Practices for Repair and Replacement Procedures

Ensuring Long-Term Safety and Compliance

When conducting plastic panel repair or replacement, it’s paramount to look beyond immediate solutions and ensure long-term safety and compliance. This involves adhering to industry standards and regulations designed to safeguard both individuals and the environment. Using approved materials and techniques that meet specific safety criteria is essential. For instance, in auto bodywork, ensuring that replacement parts are certified and that repair methods comply with manufacturer guidelines minimizes potential risks.

Moreover, proper training and certification for technicians are vital. Skilled professionals should be adept at handling plastic panel repairs and replacements, keeping up-to-date with best practices, and adhering to safety protocols. This not only guarantees the integrity of the work but also ensures that auto body work and painting processes are carried out without exposing workers or consumers to harmful substances.

When undertaking plastic panel repair or replacement, adhering to safety regulations is paramount. By understanding industry standards, following best practices, and ensuring long-term compliance, professionals can effectively mitigate risks associated with these procedures. Implementing these measures not only guarantees the integrity of structures but also promotes the safe handling of materials, ultimately contributing to a more secure environment in various sectors.