Using genuine manufacturer parts for auto body repairs ensures superior quality, safety, and reliability compared to generic alternatives. They meet specific performance standards, come with robust warranties, and maintain vehicle integrity, including critical safety systems. Staying compliant with OEM regulations is vital for car manufacturers and repair centers to avoid safety hazards, legal issues, and decreased resale value.

In the automotive industry, ensuring vehicle longevity and safety goes beyond routine maintenance. A key factor often overlooked is the use of genuine manufacturer parts (GMPs). While aftermarket alternatives may be tempting, GMPs offer unparalleled quality and compatibility, crucial for optimal performance. This article delves into the significance of compliance with genuine parts standards, exploring challenges in the auto industry and highlighting benefits that extend from enhanced safety to extended vehicle life.

- Understanding Genuine Manufacturer Parts: The Basics

- Compliance Challenges in the Auto Industry

- Benefits of Using Genuine Parts for Longevity and Safety

Understanding Genuine Manufacturer Parts: The Basics

Genuine manufacturer parts are exactly what their name suggests – components directly sourced from the original equipment manufacturer (OEM) of a vehicle. These aren’t generic or aftermarket replacements, but exact replicas designed and built to meet the specific standards and specifications set by the carmaker. Using genuine manufacturer parts is crucial for several reasons, particularly when it comes to ensuring optimal performance and reliability in car repair services.

When you opt for genuine parts during auto painting or hail damage repair, you’re benefiting from the manufacturer’s extensive research and development. These parts are engineered to seamlessly integrate with your vehicle’s existing systems, guaranteeing a perfect fit and seamless operation. Moreover, OEM parts often come with robust warranties, offering peace of mind and added protection against future failures. This level of quality control is missing in generic alternatives, which may not meet the same rigorous standards, potentially compromising the safety and performance of your vehicle.

Compliance Challenges in the Auto Industry

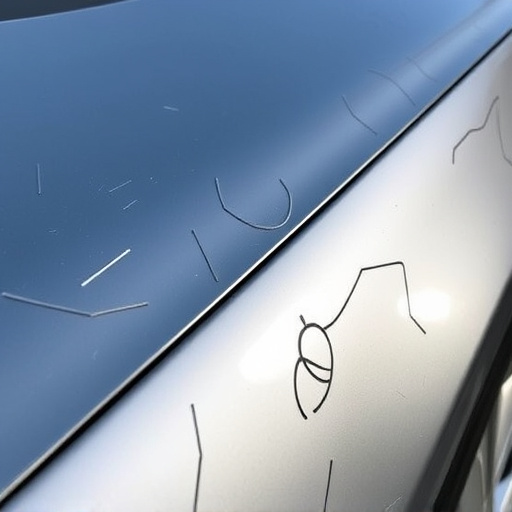

In the dynamic auto industry, compliance with ever-evolving regulations presents a significant challenge for manufacturers and collision repair centers alike. The use of genuine manufacturer parts is a critical aspect of ensuring vehicle safety and reliability, yet navigating the complex landscape of standards and certifications can be daunting. With stringent requirements for materials, manufacturing processes, and quality control in car restoration and vehicle paint repair, staying compliant is not just about meeting legal obligations but also maintaining customer trust and vehicle performance.

Manufacturers face the dual task of keeping up with technological advancements while adhering to established norms, especially as new safety features and material innovations emerge. This challenge extends to collision repair centers, which must source authentic parts to ensure proper repairs that align with original equipment manufacturer (OEM) specifications. The implications of non-compliance can be severe, leading to potential safety hazards, reduced vehicle resale value, and legal repercussions for both manufacturers and repair facilities.

Benefits of Using Genuine Parts for Longevity and Safety

Using genuine manufacturer parts for auto body repairs and collision repair offers significant advantages that go beyond mere aesthetics in vehicle restoration. These original equipment components are designed and engineered to meet specific performance standards set by the manufacturers, ensuring optimal functionality and safety features. The precision-milled materials and cutting-edge manufacturing processes guarantee a seamless fit during installation, reducing the risk of future mechanical issues.

Moreover, genuine parts often come with enhanced warranty coverage, providing peace of mind for vehicle owners. This ensures that any potential problems arising from defects or malfunctions will be addressed efficiently, minimizing downtime and repair costs. The use of authentic parts is especially critical in maintaining the integrity of safety systems, such as brakes, airbags, and lighting mechanisms, which are paramount for the well-being of drivers and passengers.

Genuine manufacturer parts play a pivotal role in ensuring vehicle longevity and safety. By adhering to compliance standards, auto industries can mitigate risks and provide consumers with high-quality products. The benefits of using authentic parts are clear: enhanced performance, improved reliability, and peace of mind. Staying informed about these regulations is crucial for both manufacturers and consumers alike, fostering a market that values safety and quality.