Before replacing frame rails, conduct thorough damage assessments and strategic planning. Sourcing compatible rails from reputable suppliers is crucial for proper alignment and safety standards. Modern tools and methods streamline the process, reducing repair times and ensuring high-quality results while maintaining structural integrity.

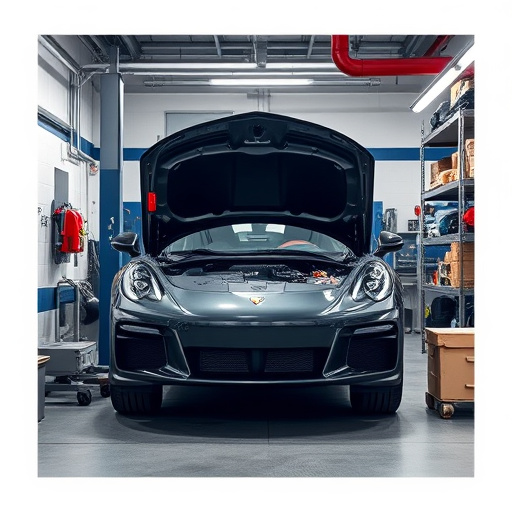

Efficient frame rail replacement is a critical process for auto body shops, ensuring vehicle structural integrity and customer satisfaction. This article explores best practices for a streamlined workflow. We’ll guide you through assessing frame rail damage and planning, sourcing compatible replacement rails, and adopting installation techniques that prioritize speed and precision. By following these steps, you can enhance your shop’s efficiency and deliver high-quality frame rail replacement services.

- Assessing Frame Rail Damage and Planning

- Sourcing Compatible Replacement Rails

- Streamlined Installation Techniques for Speed and Precision

Assessing Frame Rail Damage and Planning

Before initiating any frame rail replacement, a thorough assessment of the damage is crucial. This involves meticulous inspection of the frame’s structural integrity, identifying areas of stress concentration, and evaluating potential impact on safety standards. Technicians in auto repair shops should consider both visual cues and advanced diagnostic tools to accurately gauge the extent of frame rail damage. Planning for replacement involves gathering necessary materials, ensuring compatibility with the vehicle’s make and model, and factoring in labor costs associated with collision damage repair.

A well-planned frame rail replacement workflow streamlines the process, leading to faster turnaround times and potentially saving clients money. By balancing precision assessment with strategic planning, auto repair shops can deliver high-quality results, offering tire services that restore vehicles to their pre-accident condition, while also enhancing safety for future drives.

Sourcing Compatible Replacement Rails

When undertaking a frame rail replacement, one of the most critical steps is sourcing compatible rails. This process demands meticulous attention to ensure the new rails align with your vehicle’s make and model. Autbody shops should turn to reputable suppliers who specialize in automotive parts, especially those offering a range of options for different car types.

A quick online search for “auto repair near me” or a visit to local auto body services can help you find professionals well-versed in frame rail replacement. They can guide you in selecting the right rails, ensuring they meet safety standards and fit perfectly, thereby streamlining your automotive repair process.

Streamlined Installation Techniques for Speed and Precision

In the realm of automotive repairs, especially for those indulging in classic car restoration, efficient frame rail replacement is a game-changer. Streamlined installation techniques have revolutionized the process, ensuring speed and precision. Auto repair services now employ advanced tools and methods to simplify what was once a labor-intensive task. This involves using specialized equipment that aligns and secures the new frame rails with exacting measurements, minimizing adjustments and errors.

The adoption of these modern practices has significantly shortened the frame rail replacement process, enabling automotive repair services to deliver high-quality results more promptly. It’s not just about speed; precision is paramount to ensure structural integrity and long-lasting repairs in both contemporary and classic vehicles.

Efficient frame rail replacement is a multifaceted process that requires careful planning, sourcing of compatible parts, and streamlined installation techniques. By assiduously following best practices outlined in this article—from assessing damage and planning to sourcing replacements and implementing precise installation methods—automotive professionals can significantly enhance workflow efficiency, ensuring top-quality results in less time. These strategies are instrumental in minimizing downtime and maximizing productivity during frame rail replacement procedures.