Factory seam duplication is a critical process in modern vehicle manufacturing and maintenance, ensuring quality control, structural integrity, and safety standards. It accurately replicates seams from original parts, reducing defects, minimizing rework costs, and enabling efficient paintless dent repairs. Skilled technicians use specialized tools to maintain aesthetic and functional excellence, preserving car value for high-quality bodywork and reputable restoration services.

In modern vehicle manufacturing, factory seam duplication plays a pivotal role in enhancing overall vehicle quality. This precise process ensures that seams on parts like panels and interiors are consistent across every unit rolled off the assembly line. By mimicking the exact conditions of factory production, factory seam duplication catches defects early, leading to significant cost savings and efficiency. Moreover, it bolsters safety and reliability, as consistent seam quality is paramount for vehicle integrity.

- Enhancing Quality Control: Factory Seam Duplication

- Cost Savings and Efficiency in Manufacturing

- Ensuring Safety and Reliability Through Duplication

Enhancing Quality Control: Factory Seam Duplication

Factory seam duplication plays a pivotal role in enhancing quality control within modern vehicle manufacturing. By accurately replicating seams from original parts, this process ensures consistency and precision across every component, be it in the construction of new bodies or during intricate autobody repairs. This meticulous approach significantly reduces the likelihood of defects and deviations, ultimately leading to improved structural integrity.

Moreover, factory seam duplication becomes even more critical in scenarios involving tire services or car collision repair. In these cases, precise duplication guarantees that repaired vehicles maintain their original standard of quality and safety. This is particularly crucial for preserving the vehicle’s overall performance and reliability after such services, ensuring drivers can continue to experience smooth rides without compromising on safety measures.

Cost Savings and Efficiency in Manufacturing

Factory seam duplication is a process that plays a significant role in modern vehicle manufacturing, offering substantial cost savings and operational efficiency. By accurately duplicating factory seams, car bodywork services can streamline the production line, reducing the time and labor required for manual repairs or replacements. This precision ensures that every vehicle leaves the assembly line with consistent quality standards, minimizing the need for costly rework.

Moreover, the ability to perform paintless dent repair using advanced techniques, often facilitated by factory seam duplication, further enhances efficiency. Auto body services can quickly and effectively address minor dents and scratches without the need for extensive repainting or panel replacement. This not only saves on materials and labor costs but also reduces downtime for vehicle owners, making it a game-changer in the industry.

Ensuring Safety and Reliability Through Duplication

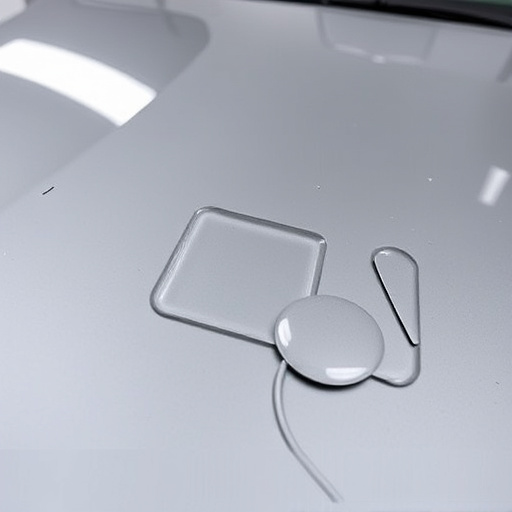

In modern vehicles, factory seam duplication plays a pivotal role in ensuring safety and reliability on the road. Every vehicle’s exterior is composed of numerous panels, meticulously joined together through precise seams. Duplicating these seams during repairs or restoration closely mirrors the original factory work, maintaining structural integrity and aesthetic precision. This meticulous process involves skilled technicians who employ specialized tools and techniques to recreate the exact specifications set by the manufacturer.

By replicating the factory seam duplication process, car repair shops and restoration specialists can guarantee that the vehicle’s body is as robust and safe as when it left the assembly line. It prevents potential weaknesses or structural issues that could compromise the overall performance and security of the vehicle. Moreover, this level of craftsmanship contributes to preserving the car’s value, making it a key aspect in high-quality car bodywork services and a vital component for any reputable car restoration process.

Factory seam duplication is not just a technique but a vital process ensuring modern vehicles meet the highest standards of quality, safety, and efficiency. By duplicating seams in manufacturing, automakers can streamline production, reduce costs, and guarantee consistent results. This method is an essential tool for maintaining rigorous quality control, ultimately enhancing consumer confidence in vehicle reliability and performance.