Repair Quality Inspection (RQI) ensures auto repair accuracy and reliability through rigorous assessments of structural integrity, paint quality, engine functionality, and safety systems like airbag mechanisms and crash sensors. Standardized procedures, trained personnel, identical assessment tools, regular equipment calibration, clear communication, and precise documentation are best practices for accurate RQI results.

In the realm of safety-critical industries, ensuring robust repair quality inspection (RQI) processes is paramount. This article delves into the intricacies of Safety System Verification within RQI, a process that safeguards against potential hazards and ensures product reliability. We explore foundational concepts, highlighting the key components essential for effective verification. Furthermore, best practices are presented to optimize accuracy, minimizing errors and maximizing safety in repair quality inspection.

- Understanding Repair Quality Inspection Basics

- Key Components of Safety System Verification

- Best Practices for Ensuring Accurate Results

Understanding Repair Quality Inspection Basics

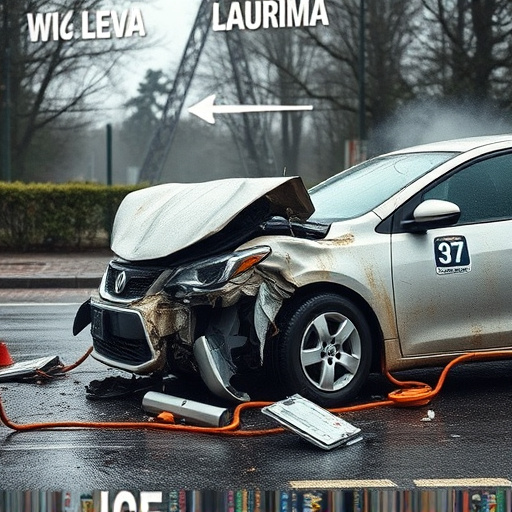

Repair Quality Inspection is a critical process that ensures the accuracy and reliability of automotive repairs. At its core, it involves a systematic evaluation of vehicles post-repair to verify that all work has been performed to the highest standards. This meticulous inspection includes checking structural integrity, paint quality (in cases like car dent removal), engine functionality, and overall vehicle safety. It’s not just about identifying visible damages; it delves into the intricate workings of auto maintenance to ensure every component is in optimal condition.

Whether dealing with a minor car dent removal or complex car body repair, the inspection process remains stringent. Professionals use advanced tools and their expertise to assess repairs, often employing visual inspections, diagnostic scans, and manual tests. The goal is not just to fix damage but to restore the vehicle to its pre-incident condition, ensuring safety and reliability on the road. This meticulous approach is a game-changer in the automotive industry, fostering trust among customers who value their auto maintenance and repair quality.

Key Components of Safety System Verification

Safety System Verification plays a pivotal role in ensuring the integrity and reliability of repair quality inspection processes in collision repair centers. This meticulous process involves several key components that work in harmony to guarantee safe and high-quality repairs. One of the primary aspects is the comprehensive assessment of vehicle safety systems, including airbag mechanisms, crash sensors, and structural integrity checks. These thorough inspections are vital to verify that each component is functional and meets the required standards, ensuring the safety of drivers and passengers during any subsequent fender repair or dent removal processes.

Additionally, training and expertise of technicians are indispensable elements in this verification process. Skilled professionals are equipped with the knowledge to identify potential issues within complex safety systems, be it a minor malfunction in an airbag module or misalignment of crash sensors. Regular training sessions on emerging technologies and industry standards further empower these experts to stay updated and provide precise repairs, such as those required in dent removal processes, ensuring that the vehicle’s safety mechanisms remain intact and operational throughout.

Best Practices for Ensuring Accurate Results

To ensure accurate results during a repair quality inspection, several best practices should be implemented. Firstly, standardizing procedures and training all personnel involved in the inspection process is essential. Everyone, from mechanics to inspectors, needs to understand and adhere to set protocols for consistent outcomes. This includes using identical assessment criteria, tools, and methods across all inspections, regardless of whether they’re performed at an auto repair near me or a specialized body shop.

Additionally, regular calibration and maintenance of inspection equipment are crucial. Tools like measuring devices, lighting, and cameras should be checked to ensure they provide accurate data. Car body restoration and car paint repair require meticulous attention to detail, so high-quality, well-maintained tools are vital. In terms of accuracy, establishing clear communication channels among team members is also important. This includes documenting findings precisely and sharing them in a standardized format for easy comparison and analysis.

Safety System Verification plays a pivotal role in ensuring the accuracy and reliability of repair quality inspections. By understanding the basics, recognizing key components, and adopting best practices, professionals can significantly enhance the integrity of their evaluation processes. Incorporating these strategies into standard operating procedures not only boosts the overall quality of repairs but also instills confidence in the safety and efficacy of the outcome for both users and stakeholders alike.