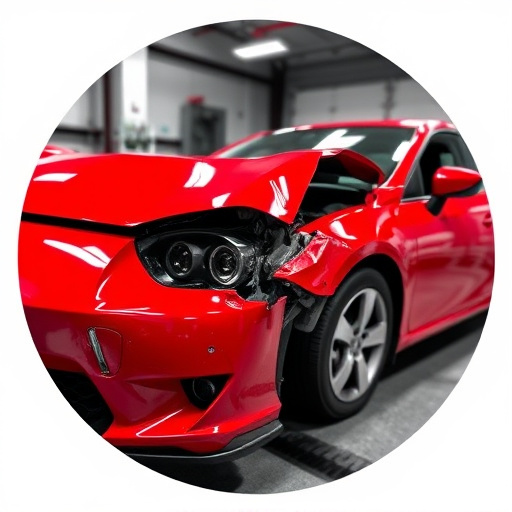

Plastic welding techniques are vital for repairing modern vehicles' complex plastic components after a crash, ensuring structural integrity and aesthetic restoration, while meeting rising demand for efficient collision repairs.

“In the realm of automotive restoration, plastic welding collision repairs have emerged as a game-changer. This innovative technique addresses common crash damage areas that traditional methods might struggle with. From crumpled fenders and bumper repairs to intricate interior components, plastic welding offers precise, durable solutions.

This article delves into the process, benefits, and applications of this modern approach, providing insights into why it’s a preferred choice for many professionals in the industry.”

- Identifying Common Car Crash Damage Repairable by Plastic Welding

- The Process of Plastic Welding for Collision Repairs: Step-by-Step Guide

- Benefits and Applications: Why Choose Plastic Welding for Collisions?

Identifying Common Car Crash Damage Repairable by Plastic Welding

In the event of a car crash, it’s crucial to identify damage that can be effectively repaired by plastic welding techniques. Many common collision areas often seen in auto accidents are suitable for this specialized process. Car body shops and collision repair centers equipped with plastic welding capabilities can address various issues, including dented or cracked plastic components such as fenders, bumpers, and door panels. These parts, when damaged, can be restored to their original condition, ensuring a seamless fit and maintaining the vehicle’s structural integrity.

Additionally, auto collision centers may encounter complex geometry and intricate designs in modern vehicles, where traditional repair methods might prove challenging. Plastic welding offers a versatile solution for repairing these intricate areas, allowing technicians to precisely mend hidden or hard-to-reach sections. By employing this advanced technique, collision repair shops can provide top-notch services, ensuring vehicles return to the road with restored aesthetics and enhanced safety features.

The Process of Plastic Welding for Collision Repairs: Step-by-Step Guide

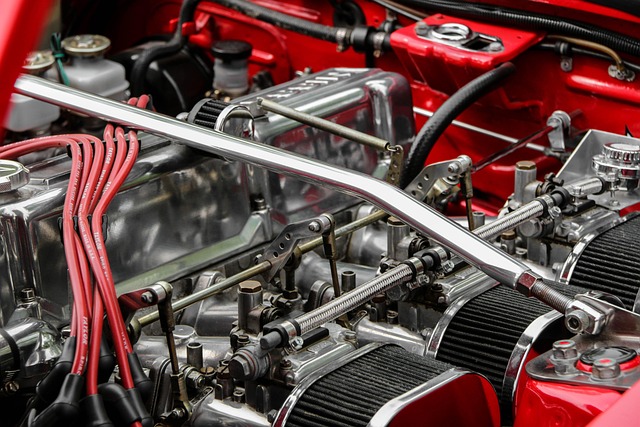

Plastic welding is a specialized process used to repair car damage, particularly common collision areas on vehicles. Unlike traditional metal welding techniques, plastic welding is tailored for thermoplastic materials found in modern car bodies. This non-invasive method fuses the damaged parts together by applying heat and pressure, creating a strong bond that matches the original material’s properties.

The process begins with thorough preparation: cleaning and degreasing the collision area to ensure optimal adhesion. Next, the welder uses specialized equipment to heat the plastic, often employing infrared technology for precise temperature control. As the plastic softens, a robotic arm or skilled technician fuses the damaged components together. Finally, cool the joint gradually, allowing it to set and cure properly. This step-by-step approach ensures minimal disruption to the car’s original structure, making plastic welding an ideal solution for intricate automotive restoration and effective in many car repair shops handling collision damage repair.

Benefits and Applications: Why Choose Plastic Welding for Collisions?

When it comes to repairing common collision areas on vehicles, plastic welding stands out as a preferred method over traditional techniques. Its benefits are numerous; it offers precision and versatility in fixing parts made from various types of plastics used in modern cars. This makes it ideal for a wide range of vehicle repair services, especially in the collision center setting.

One of the key advantages of plastic welding is its ability to preserve the structural integrity and aesthetic appeal of the damaged area. Unlike other collision repair methods, it allows for seamless bonding of plastic components without compromising the original factory finish. This ensures that vehicles not only function optimally but also retain their value and look as good as new. As such, many collision centers are now incorporating advanced plastic welding techniques into their service offerings to cater to the growing demand for efficient and effective vehicle repair services.

Plastic welding has established itself as a game-changer in the automotive industry, offering efficient and effective solutions for common collision areas. By understanding the process, benefits, and applications of this innovative technique, it’s clear that plastic welding collision repairs are a smart choice for both technicians and vehicle owners. This modern approach to car crash damage not only enhances structural integrity but also ensures superior aesthetics, making vehicles look as good as new.